Wave generator cam design method, wave generator and harmonic reducer

A technology of harmonic reducer and wave generator, applied in computer-aided design, design optimization/simulation, instruments, etc., can solve the problems of plummeting harmonic performance, depression, damage, etc., to speed up the research and development process and reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, below in conjunction with accompanying drawing and specific embodiment do further description:

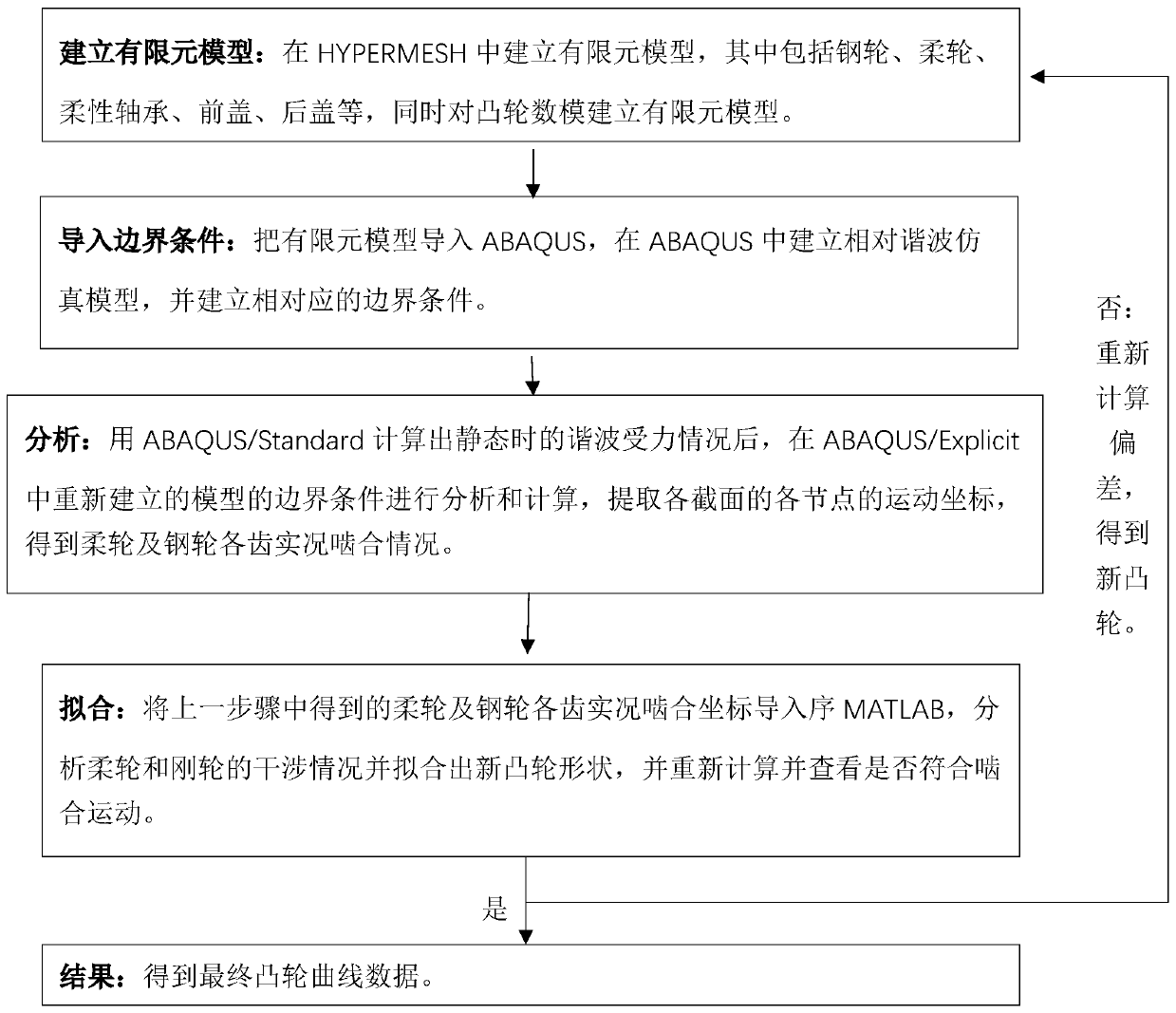

[0039] Such as figure 1 The design method of the shown wave generator cam comprises the following steps:

[0040] i. Establish finite element model

[0041] The finite element model is established in the finite element pre-processor HYPERMESH according to the harmonic reducer structure that needs to be applied to the wave generator cam. The harmonic reducer includes harmonic finite element models such as the wave generator cam, flex spline and rigid spline;

[0042] ii. Import boundary conditions

[0043] After the virtual finite element model is obtained, it is imported into the finite element analysis program ABAQUS by the finite element preprocessor HYPERMESH, and the relative harmonic simulation model is established in the finite element analysis program ABAQUS, and the corresponding boundary conditions are establish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com