High-efficiency logistics flexible sorting device

A sorting device and logistics technology, applied in the direction of sorting, conveyor objects, transportation and packaging, etc., can solve the problems of small size of sorting device, easy to break materials, hidden safety hazards, etc., and achieve convenient disassembly and maintenance, saving The effect of manufacturing cost and reducing the weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

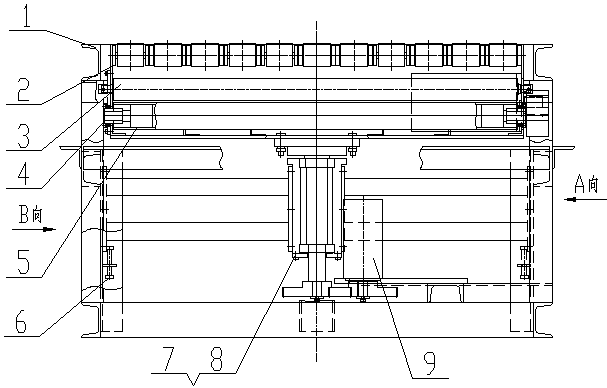

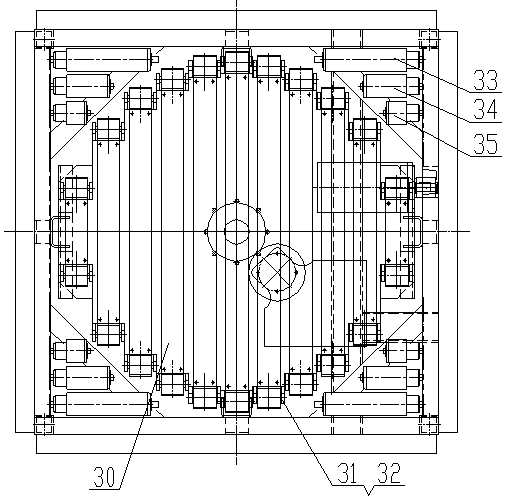

[0017] Now in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0018] The structure of the sorting device is as follows: the tension roller 3 is installed on the rotating body 2, the two shaft ends are fixed with bolts F-22, and the bolts F-22 are screwed to the fixed plate 23. The drive shaft 5 forms a revolving pair with the rotating body 2 through the sliding bearings 4 installed at both ends, and a large synchronous wheel 25 is installed at one end of the drive shaft 5 . Belt motor 28 is fixed on the rotating body 2 by bolt G-29, and the end of belt motor 28 is equipped with small synchronous wheel 26 simultaneously, and synchronous belt 27 is installed on the large synchronous wheel 25 and small synchronous wheel 26, as figure 1 with Figure 4 shown.

[0019] The shaft 16 is fixed on the lower part of the rotating body 2 through the bolt C-10 and the nut C-11. The upper part of the shaft 16 is equipped with the upper bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com