Flat wire unwinding machine

A technology of pay-off machine and flat wire, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of unfavorable production personnel for installation, replacement of wire barrels, damage to the surface protective layer of wire materials, and large space occupation and other issues to achieve the effect of shortening equipment downtime, ensuring sustainability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

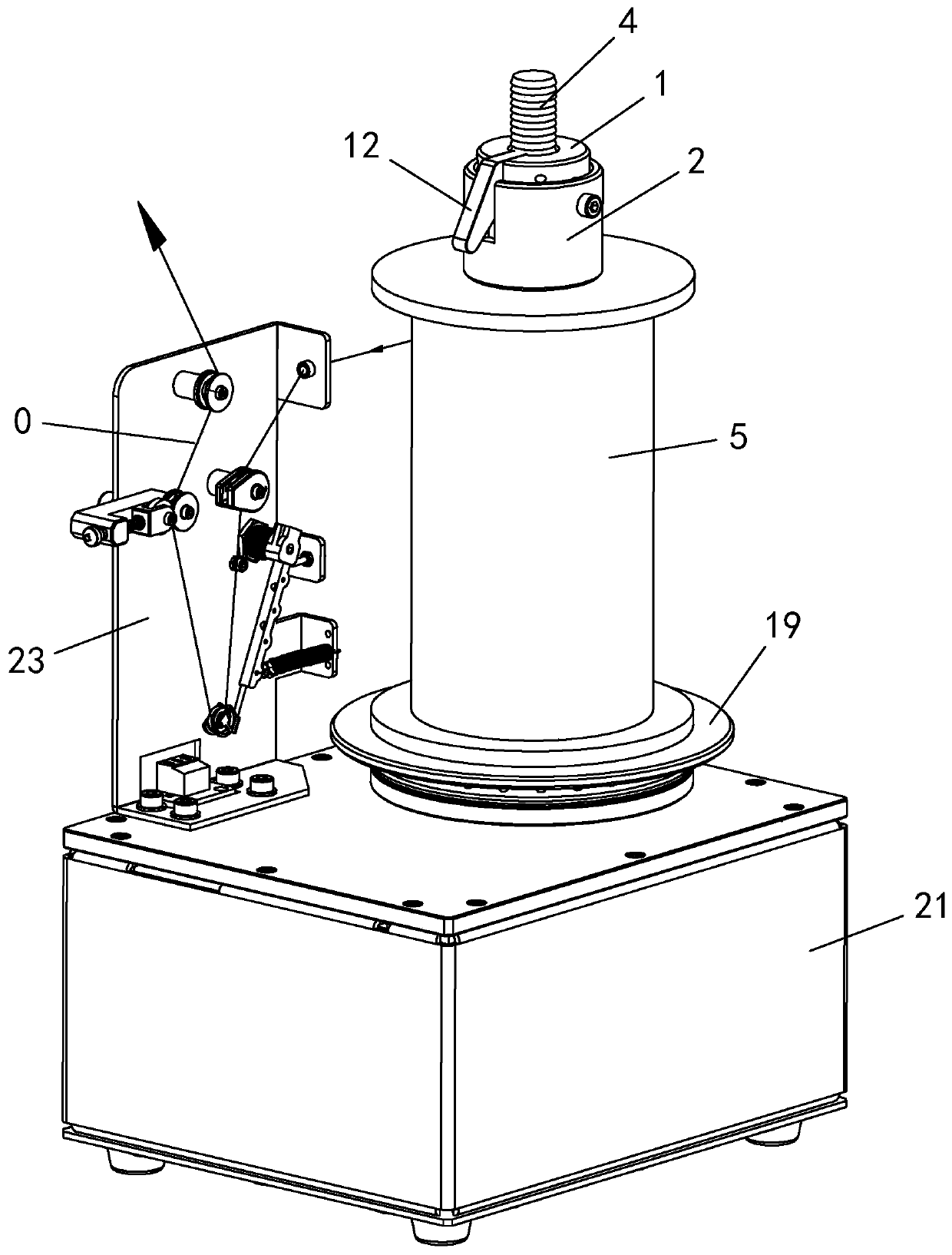

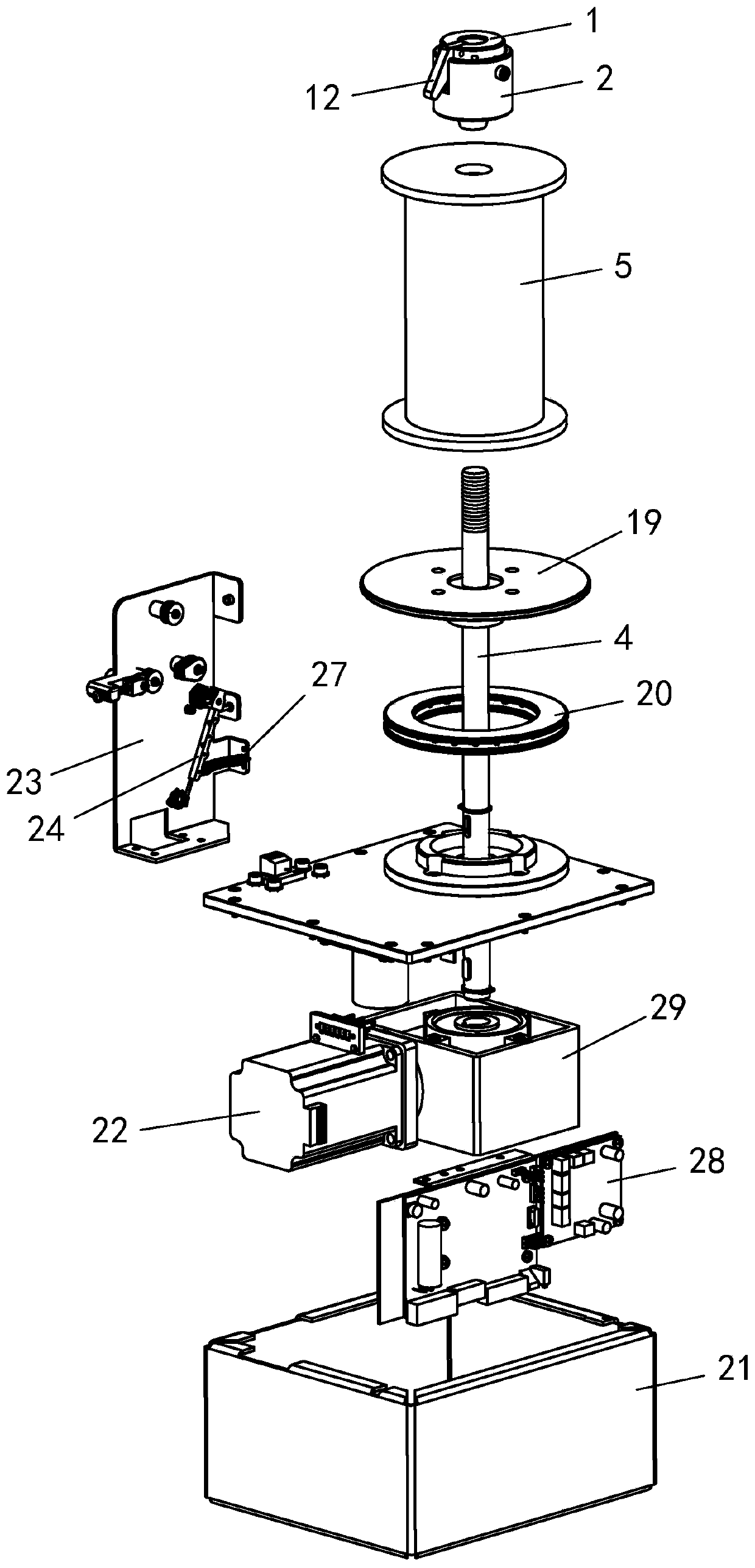

[0058] Example: see attached Figure 1~14 As shown, a flat wire pay-off machine includes a pay-off unit and a tension control unit.

[0059] Wherein, the pay-off unit includes a wire barrel quick disassembly structure and a wire barrel positioning structure.

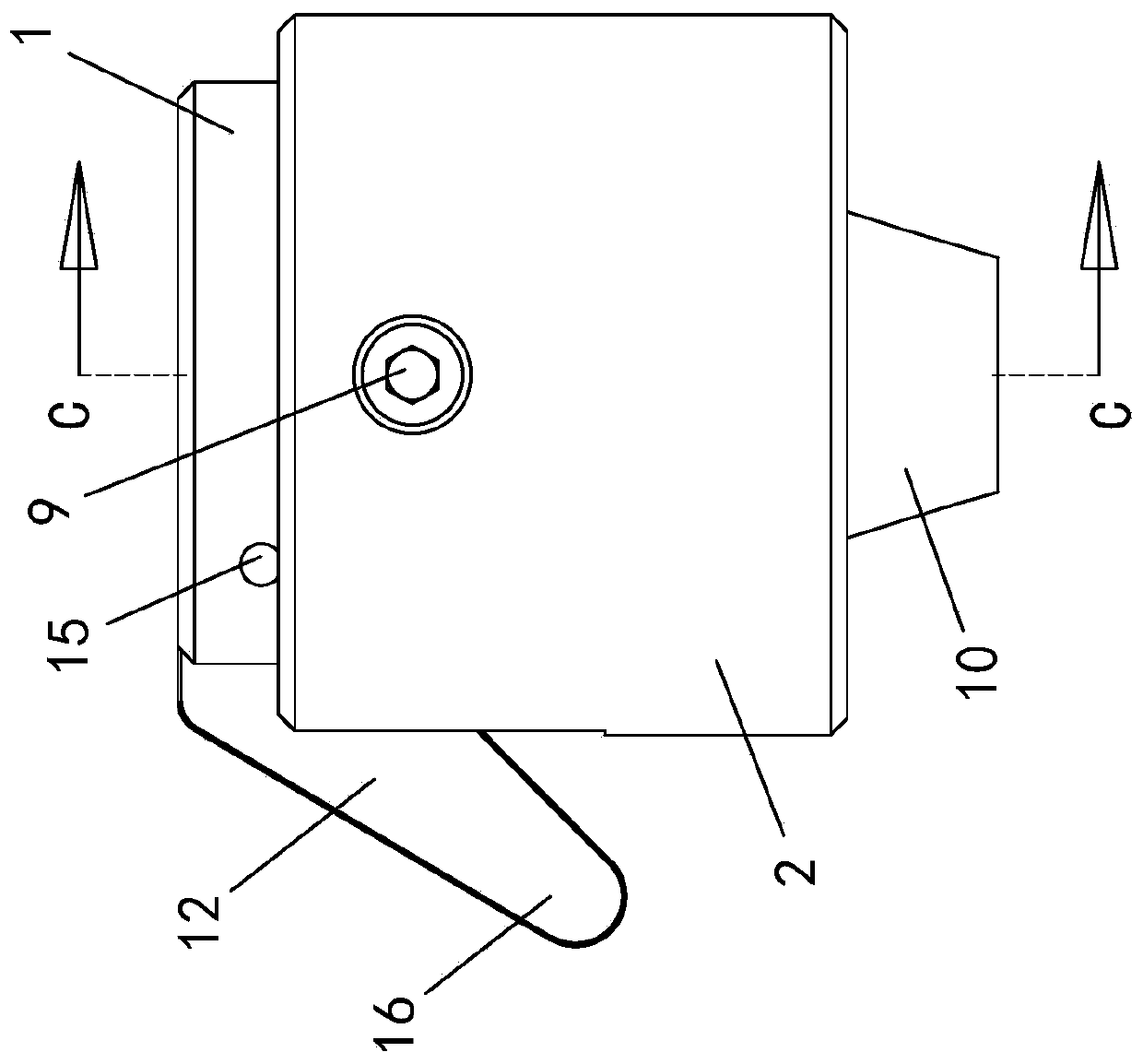

[0060] Such as Figure 3~10 As shown, the quick assembly and disassembly structure of the bobbin includes a pressing block 1 and a guide pressing cover 2 .

[0061] The middle part of the pressing block 1 is provided with a through hole 3 along the up and down direction, and the through hole 3 is used for the line barrel positioning shaft 4 of the pay-off machine to pass through.

[0062] A positioning hole 6 is arranged axially in the wire cylinder 5, and the radial width of the positioning hole 6 is greater than or equal to the radial width of the wire cylinder positioning shaft 4; when the wire cylinder 5 is installed, the wire cylinder 5 passes through the The positioning hole 6 is sleeved on the spool positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com