Production process of optically clear adhesive (OCA) optical adhesive

A production process, optical adhesive technology, applied in the direction of adhesives, films/sheets without carriers, etc., can solve the problems of high waste discharge process, small hole area, not very good, etc., to achieve good waste discharge effect, material quality Soft, close-fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

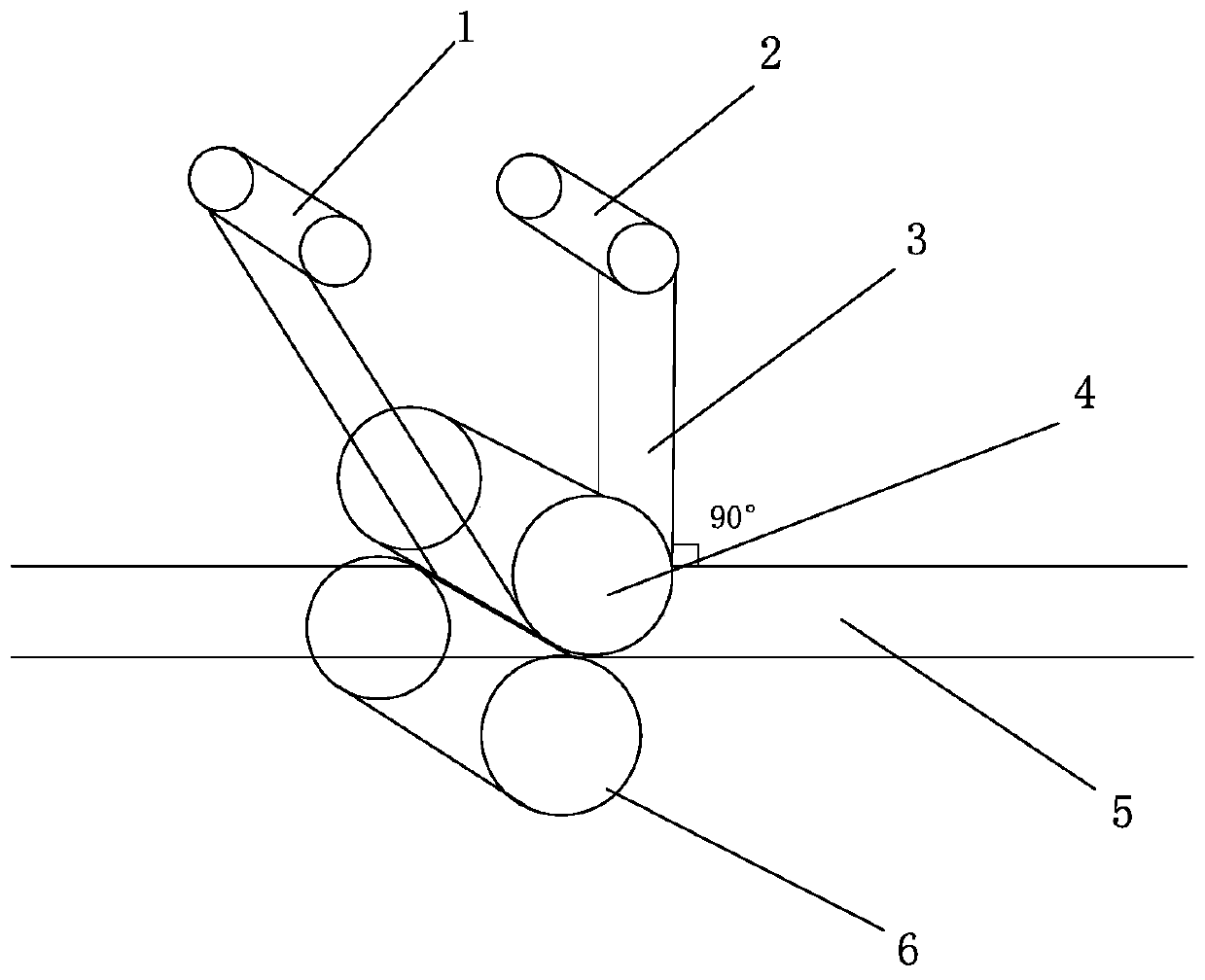

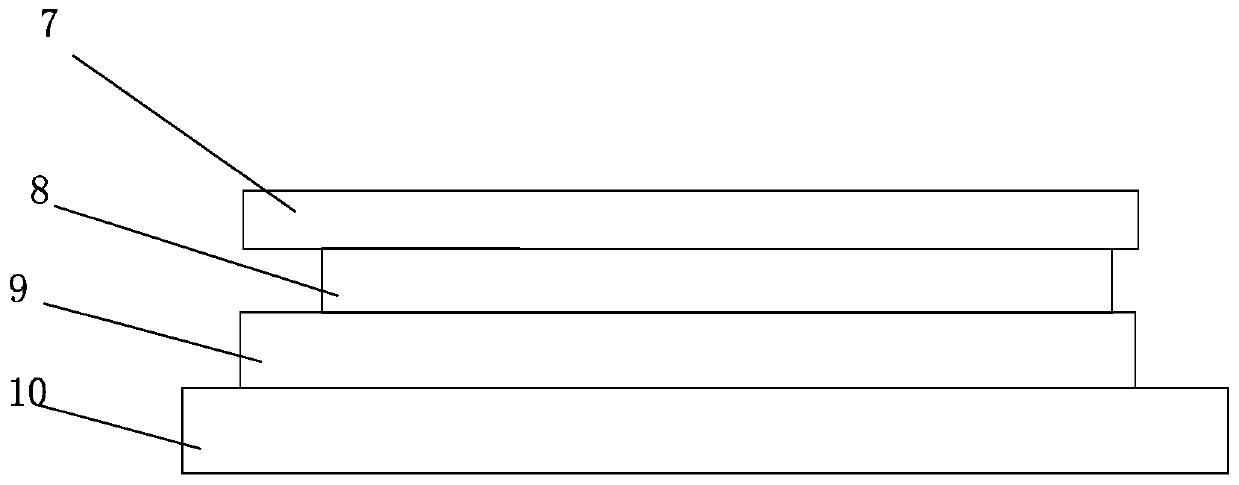

[0028] Embodiment 1: refer to Figure 1-Figure 4 , a production process of OCA optical adhesive, the OCA optical adhesive semi-finished product 5 produced in the present embodiment includes light release film layer 7, OCA layer 8, heavy release film layer 9 and bottom film layer arranged in sequence from top to bottom 10. The bottom film layer 10 is used to protect the OCA optical glue, and the production process includes the following steps:

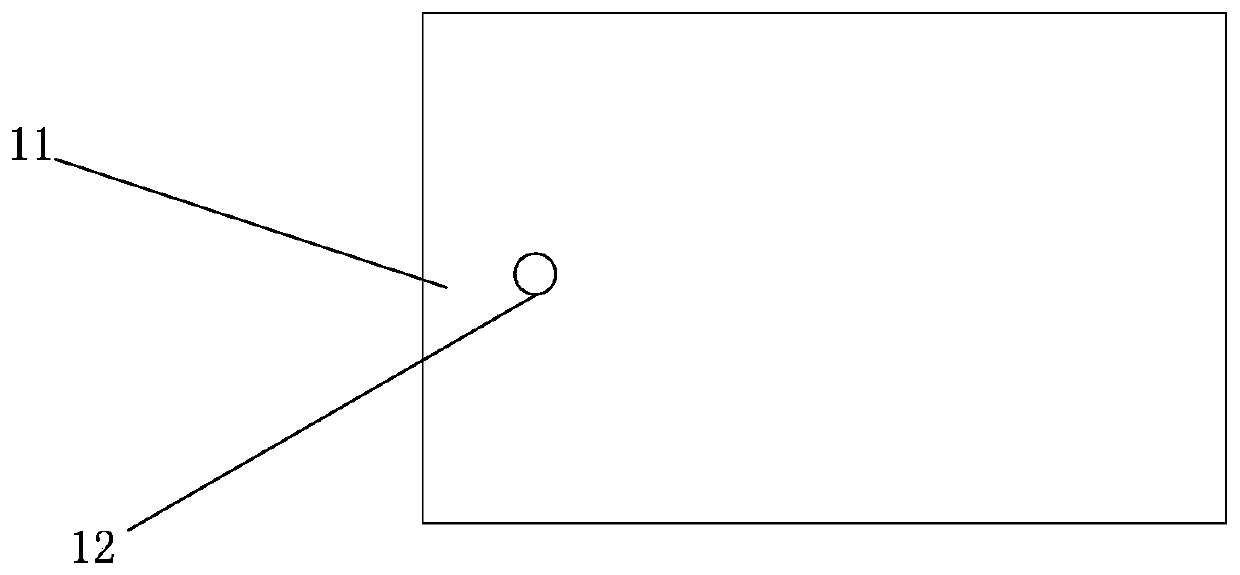

[0029] S1. Put the OCA optical adhesive semi-finished product 5 flat on the workbench, and die-cutting tool 11 is punched from top to bottom. The die-cutting tool 11 is provided with a circular cutter 12, and the light release film layer 7 and the OCA layer 8 Completely cut off, the heavy release film layer 9 is cut in half to form a circular hole;

[0030] S2. Remove the light-release film layer 7 above the small hole. The specific method is to attach the Marathon tape to the light-release film layer 7, and the Marla tape sticks to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com