A kind of method for extracting rubidium in fly ash

A fly ash and leaching technology, which is applied in the field of extracting rubidium from fly ash and recycling fly ash, can solve the problems of a large amount of strong alkaline wastewater environment, increase production cost, pollution, etc., and avoid the generation of a large number of low-value by-products , reduce the amount of use, reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

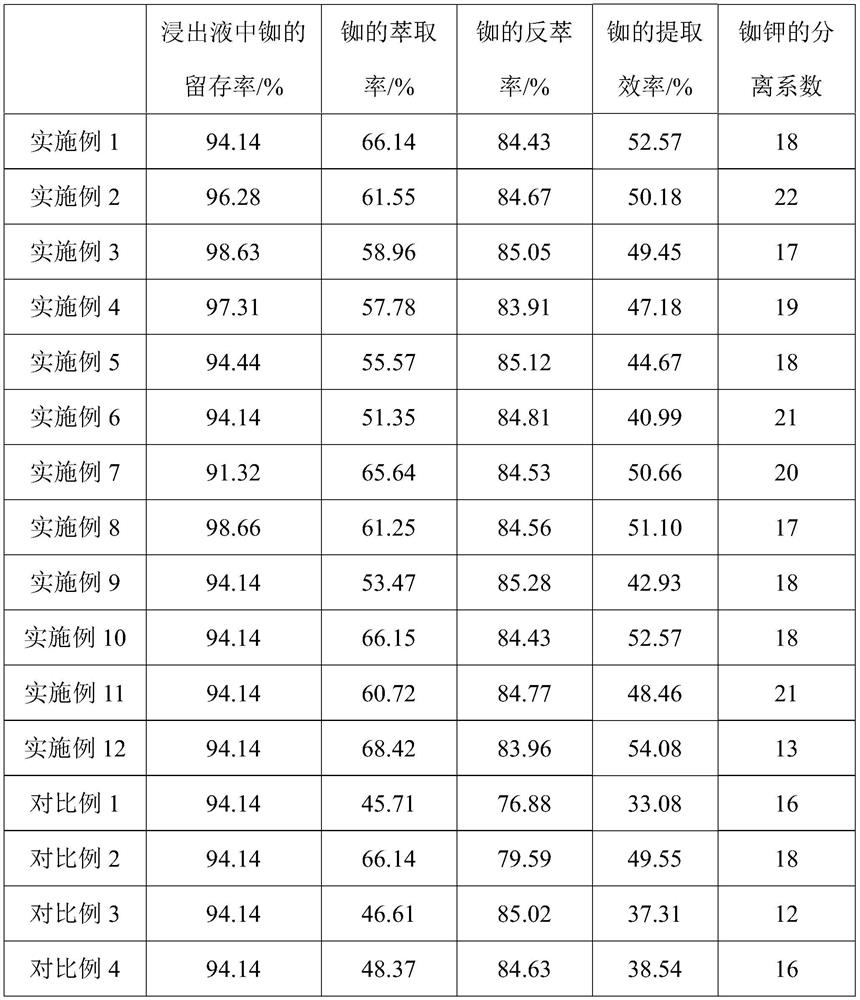

Examples

Embodiment 1

[0068] The present embodiment provides a method for extracting rubidium in fly ash, said method comprising the steps of:

[0069] (1) use the aqueous solution of 0.8% sodium dimethyl dithiocarbamate to leach fly ash for 2h at room temperature, the liquid-solid ratio of the aqueous solution of sodium dimethyl dithiocarbamate and fly ash is 5: 1. Solid-liquid separation to obtain leach residue and leachate with a pH value of 12;

[0070] (2) mixing sodium carbonate and step (1) gained leaching solution, solid-liquid separation after precipitation is complete, obtain precipitation slag and precipitation liquid, the mass ratio of described sodium carbonate and fly ash is 1.5:1;

[0071] (3) Use an extractant to extract the precipitated liquid obtained in step (2) for 5h at room temperature, and separate the liquids to obtain an organic phase containing rubidium and the first aqueous phase. The extractant is a mixture of t-BAMBP and sulfonated kerosene Organic solution, the concen...

Embodiment 2

[0075] The present embodiment provides a method for extracting rubidium in fly ash, said method comprising the steps of:

[0076] (1) Use an aqueous solution of sodium diethyldithiocarbamate with a mass fraction of 0.5 to leach fly ash for 5 hours at room temperature, and the liquid-solid ratio of the aqueous solution of sodium diethyldithiocarbamate to fly ash is 10:1 , solid-liquid separation to obtain leach slag and leachate with a pH value of 11.5;

[0077] (2) mixing sodium carbonate and step (1) gained leaching solution, solid-liquid separation after precipitation is complete, obtain precipitation slag and precipitation liquid, the mass ratio of described sodium carbonate and fly ash is 1.2:1;

[0078] (3) Use an extractant to extract the precipitated liquid obtained in step (2) for 6 hours at room temperature, and separate the liquids to obtain an organic phase containing rubidium and the first aqueous phase. The extractant is a mixture of t-BAMBP and sulfonated kerosen...

Embodiment 3

[0082] The present embodiment provides a method for extracting rubidium in fly ash, said method comprising the steps of:

[0083] (1) Use the aqueous solution of 1% polyethyleneimine dithiocarbamate to leaching fly ash at room temperature for 6 hours, the aqueous solution of polyethyleneimine dithiocarbamate and fly ash The liquid-solid ratio is 4:1, the solid-liquid is separated, and the leach residue and the leachate with a pH value of 12.5 are obtained;

[0084] (2) mixing sodium carbonate and step (1) gained leaching solution, solid-liquid separation after precipitation is complete, obtain precipitation slag and precipitation liquid, the mass ratio of described sodium carbonate and fly ash is 1.8:1;

[0085] (3) Use an extractant to extract the precipitated liquid obtained in step (2) for 2 hours at room temperature, and separate the liquids to obtain an organic phase containing rubidium and the first aqueous phase. The extractant is an organic compound formed by mixing t-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com