A cluster cathode micro-arc oxidation film preparation device and method

A cathode micro-arc and preparation device technology, which is applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve the problems of high power requirements, low processing efficiency of small-area workpieces, and low micro-arc oxidation processing accuracy. , to achieve the effects of strong controllability, reduced processing costs, and fast matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

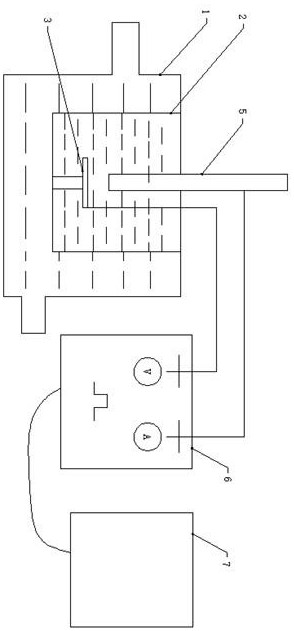

[0033] like figure 1 , 2 As shown, a cluster cathode micro-arc oxidation film preparation device includes a distance adjustment device, a cooling tank 1, an electrolytic tank 2, a cluster cathode 5, a power supply 6 and a main control computer 7.

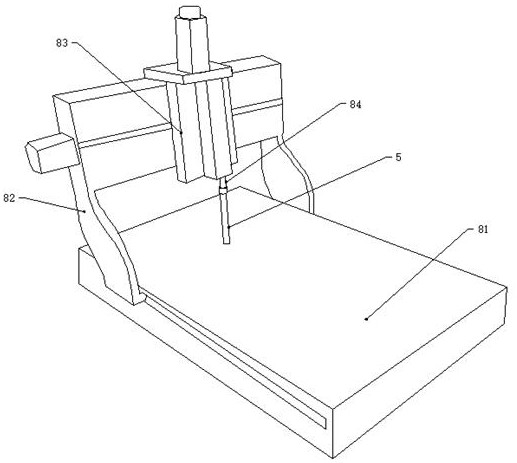

[0034] like figure 2 As shown, the distance adjustment device includes a workbench 81, a vertical arm 82, a traverse slider 83 and a telescopic rod 84, and the vertical arm 82 can linearly reciprocate on the workbench 81 under the action of the servo motor-driven ball screw transmission mechanism; The traverse slider 83 is arranged on the vertical arm 82, and can reciprocate linearly on the vertical arm 82 under the action of the servo motor-driven ball screw transmission mechanism; the telescopic rod 84 is arranged on the traverse slider 83, Under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com