Target-absorbing superfine crusher with accelerating rotation

An ultra-fine pulverizer and accelerated rotation technology, applied in grain processing and other directions, can solve the problems of high energy consumption, low efficiency, purity impact, etc., and achieve the effects of high energy utilization, increased movement speed, and strong pulverization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

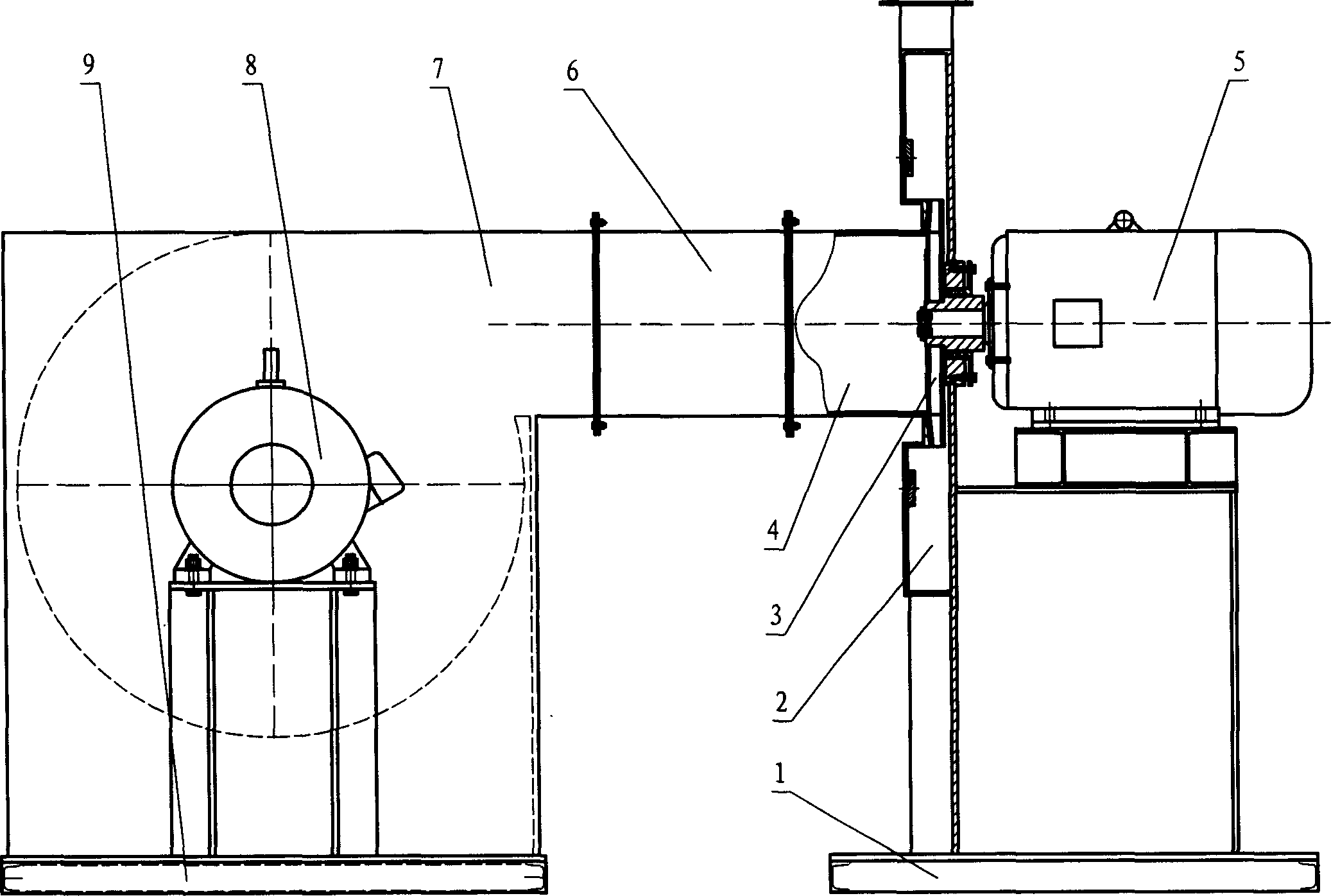

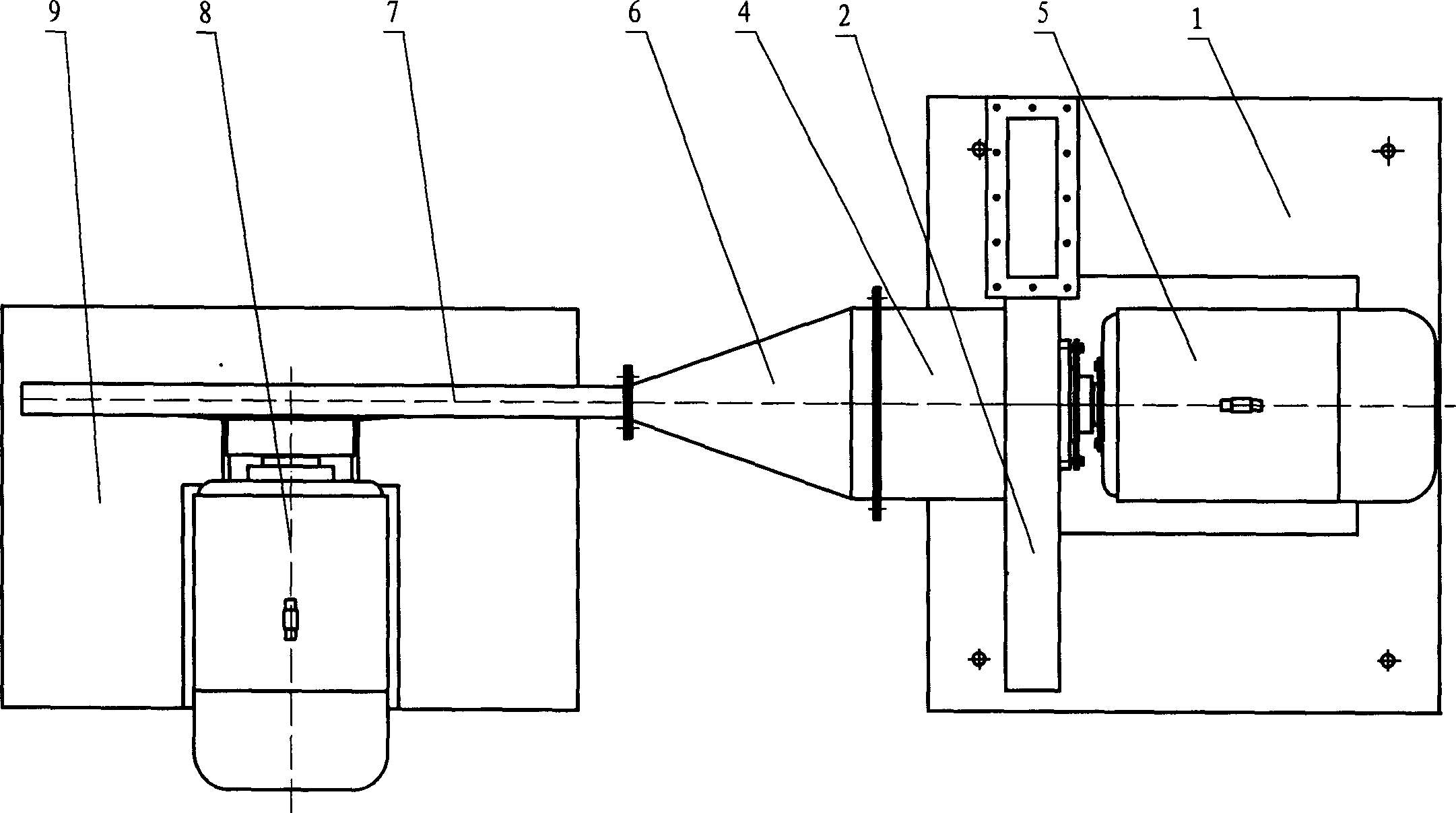

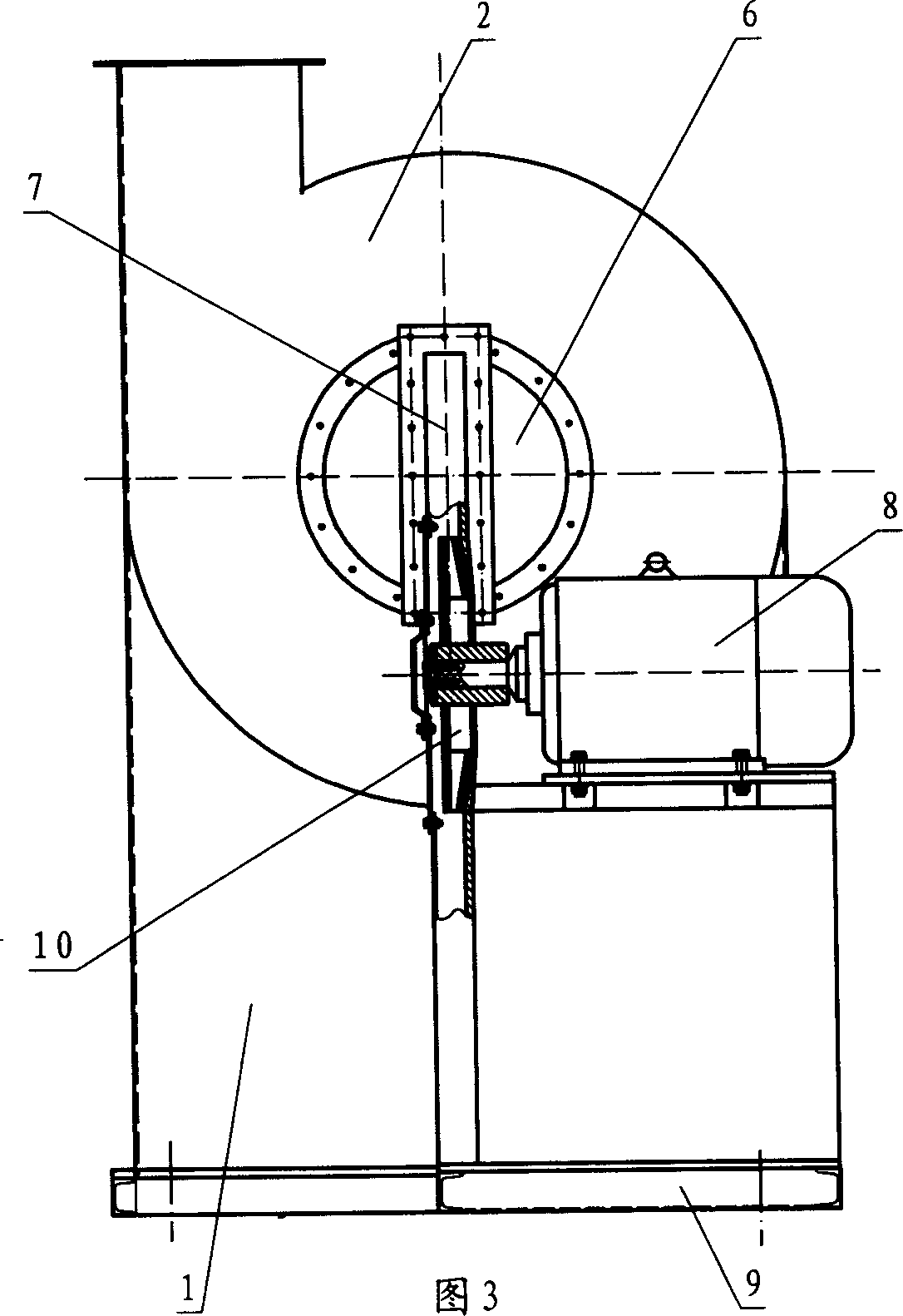

[0014] As shown in the accompanying drawings, the present invention has a frame 1, and the frame 1 is welded with profiles and steel plates; a chassis 2 and a power unit 5 are housed on the frame 1, and the power unit 5 is an electric motor, which can also be other The power unit, the chassis 2 is circular, the center of which is the feed end, and the discharge end is located at the upper end of the chassis 2; a semi-closed target wheel 3 is installed in the chassis 2, and the semi-closed target wheel 3 is installed on the output shaft of the power unit 5 On, constitute the rotary suction target type pulverizing device, described semi-closed target wheel 3 has a wheel hub 14, and a circular target plate 13 is arranged on the wheel hub 14, and several target blades 12 are arranged on the circular target plate 13, the target The leaves 12 are evenly distributed on the circular target plate 13, and the hub 14, the circular target plate 13 and the target leaf 12 are welded together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com