Circulating primary grinding machine

A preliminary grinding and circulating technology, applied in the field of grinding machines, can solve the problems of weak pertinence and achieve the effect of speeding up the flow, increasing the number of collisions, and clear functional purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below according to the drawings and embodiments.

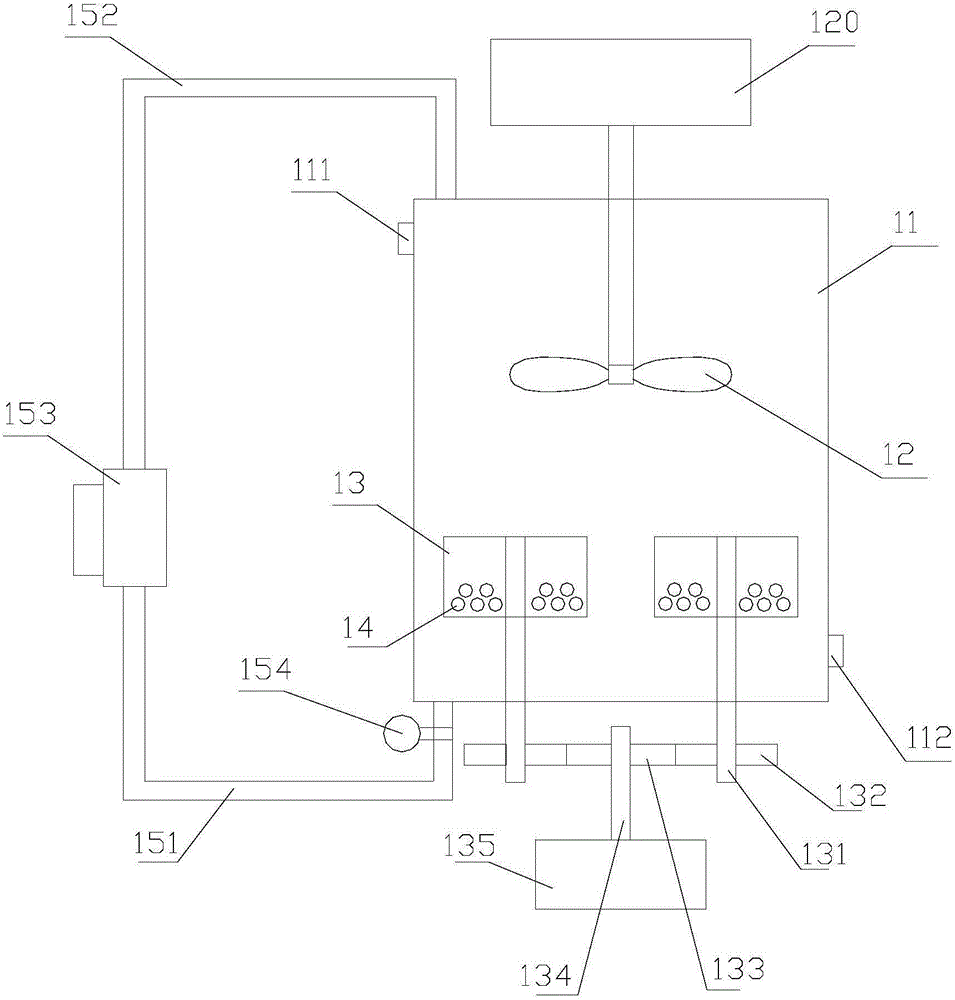

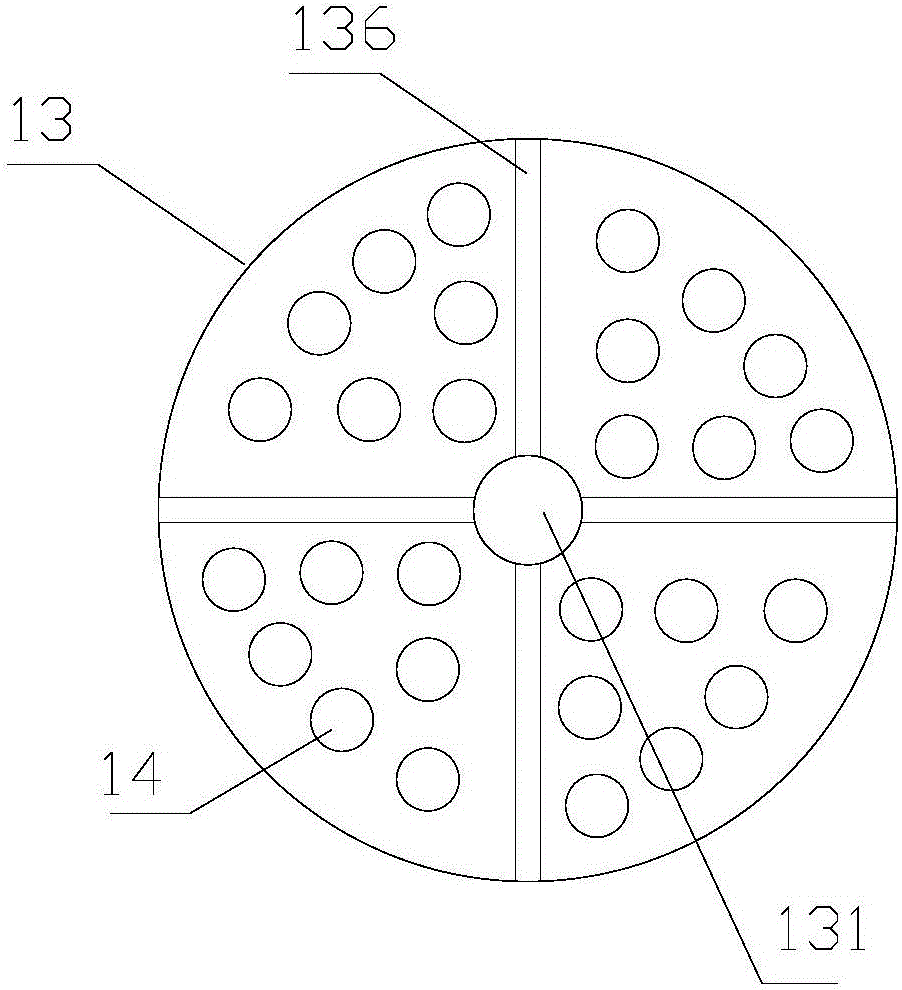

[0014] figure 1 It is the structural representation of the circulation type primary grinder of the present invention, figure 2 It is a top view structure schematic diagram of the grinding tank 13 of the present invention, refer to Figure 1-Figure 2 , the present invention, the circulation type preliminary grinder, comprises preliminary grinder housing 11, preliminary grinder, paddle fan 12, paddle fan driving device 120, circulation device, above-mentioned preliminary grinder shell 11 upper part is provided with preliminary grinding entrance 111, and the bottom is provided with preliminary grinding inlet 111. Grinding outlet 112, the above-mentioned paddle fan 12 is located at the upper position inside the above-mentioned preliminary grinding machine shell 11, and is driven to rotate by the above-mentioned paddle fan 12 driving device. The bottom of the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com