Device and method for grinding and descaling metal plate belts

A metal strip and descaling device technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of thick and difficult to remove metal strip scales, so as to achieve a small equipment footprint and reduce maintenance Cost, system composition simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

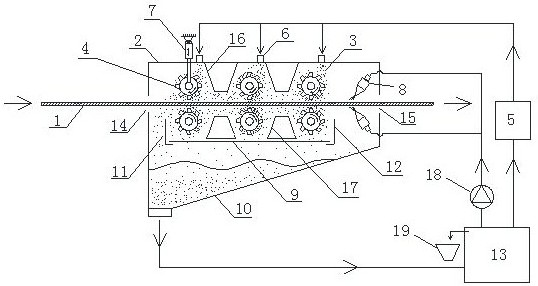

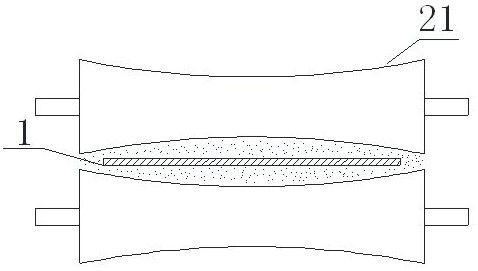

[0066] Taking the descaling of high-strength steel with conventional width and thicker side scales as an example, refer to the attached figure 1 And attached image 3 , the specific implementation is as follows:

[0067] The metal strip 1 in this embodiment has a width of 1300-1600 mm, and the steel type is a hot-rolled strip of high-strength steel B600L for automobile structure. The scale on the surface of the metal strip 1 of this steel type is difficult to remove, and the thickness of the scale at the edge of the metal strip 1 is obviously greater than that at the middle of the metal strip 1, so there is a problem that it is difficult to remove the scale at the edge. Therefore, for the metal strip of this specification 1 descaling, grinding stick 4 selection as attached image 3 The shown curved profile grinding rod 21 is to strengthen the treatment of the edge scales; during the descaling work of the grinding rod 4, the distance between the middle part of the grinding ro...

Embodiment 3

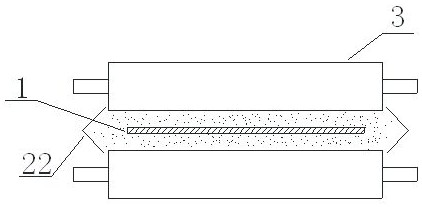

[0069] Taking the descaling of high-strength steel with narrow width specifications and thicker side scales as an example, refer to the attached figure 1 And attached Figure 4 , the specific implementation is as follows:

[0070] The metal strip 1 in this embodiment is a hot-rolled steel strip with a width of 900-1300 mm and a steel type of high-strength steel B600L for automobile structures. The scale on the surface of the metal strip 1 of this steel type is difficult to remove, and the thickness of the scale at the edge of the metal strip 1 is obviously greater than that at the middle of the metal strip 1, so there is a problem that it is difficult to remove the scale at the edge. The width is narrow, so for the descaling of the metal strip 1 of this specification, the grinding stick 4 is selected as attached Figure 4 The curved contour grinding roller 21 is shown, and the curved contour grinding roller 21 has the ability to move axially. The formula for calculating the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com