Method fordisassembling single shield dual mode TBM (tunnel boring machine) in subsea tunnel

A subsea tunnel and single-shield technology, which is applied to tunnels, earthwork drilling, mining equipment, etc., can solve the problems of inability to disassemble the machine and the inability to set up receiving shafts, etc., to eliminate construction risks, improve construction efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

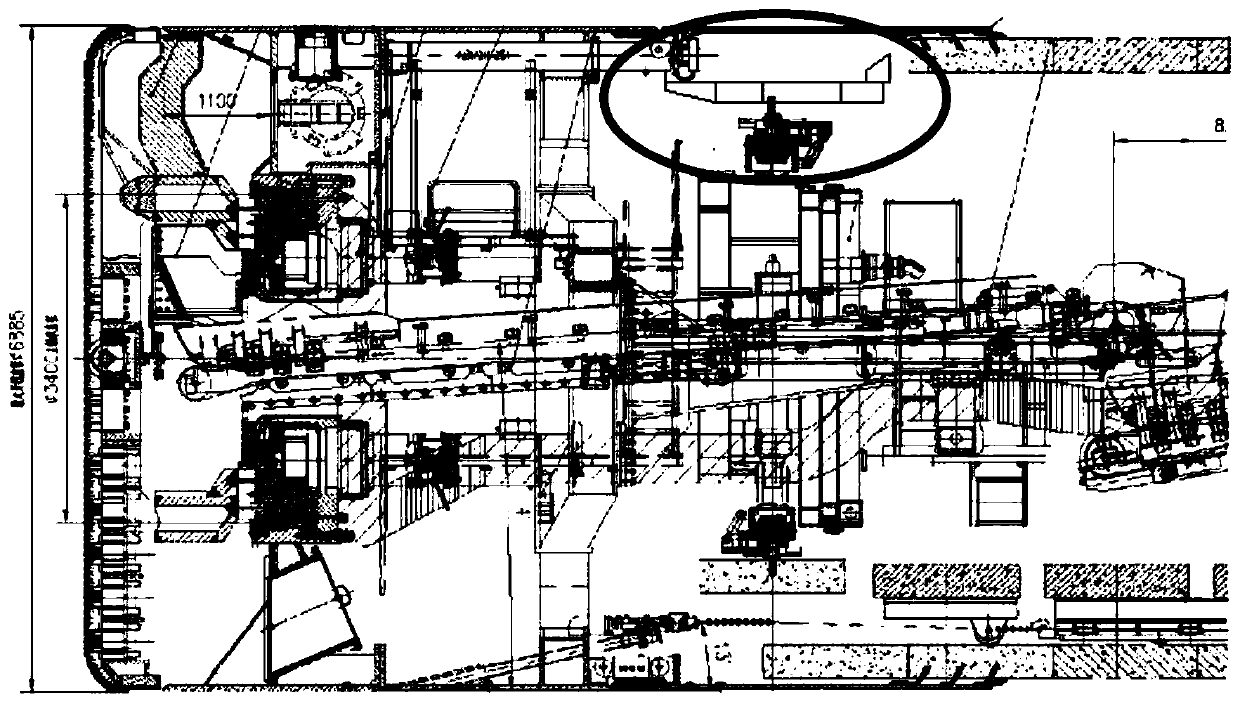

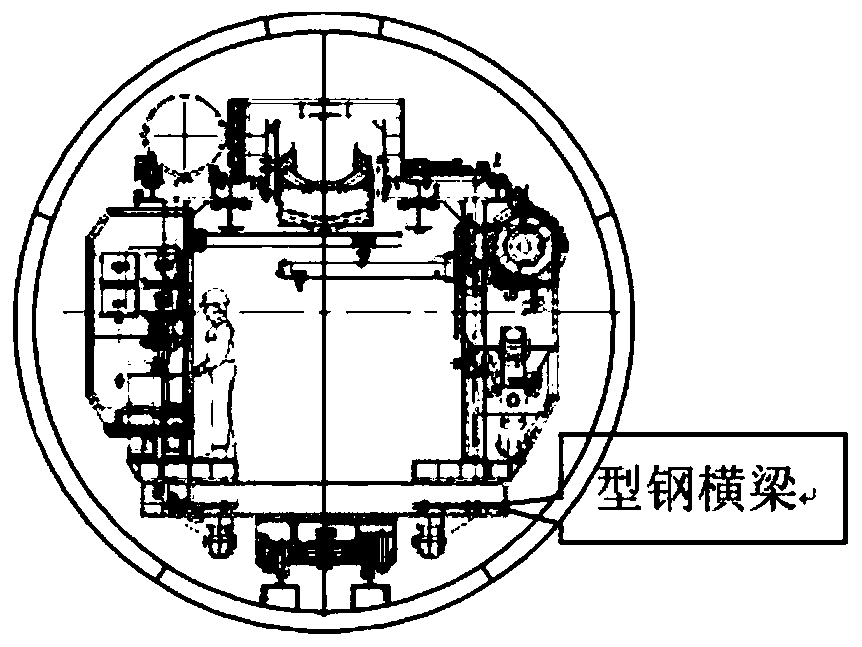

[0038] Such as Figure 1-11 As shown, a method for dismantling a single-shield dual-mode TBM in a subsea tunnel according to the present invention comprises the following steps:

[0039] A. The last ring of TBM equipment is excavated to 1870mm, and the segments are not assembled. The section steel and the shield tail are welded together to reinforce the last ring segment. At the same time, the back of the shield tail segment is grouted and reinforced to block water coming from behind;

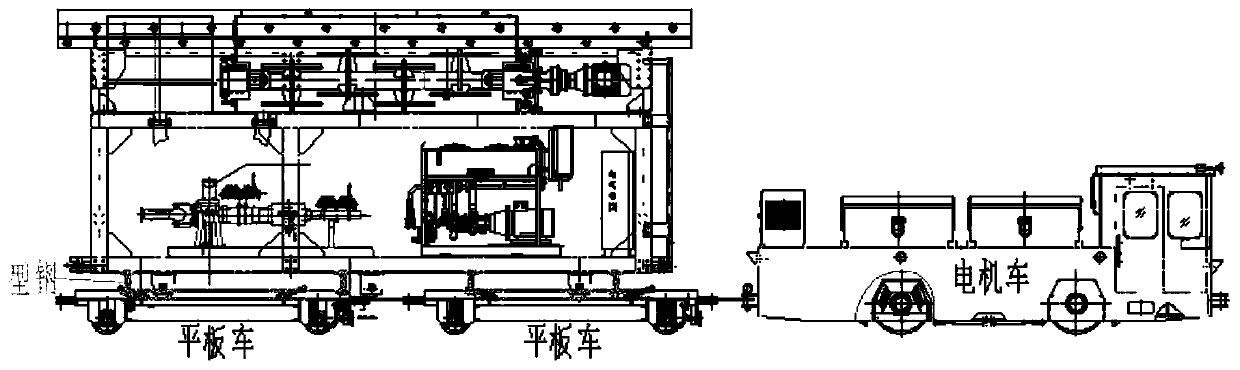

[0040] B. Use the assembly machine to dismantle the propulsion cylinder and hinged cylinder, and at the same time dismantle the walkway plate, continuous belt conveyor and segment transport trolley in the tunnel, and transport them out by electric locomotive;

[0041] C. Install steel brackets on the flatbed car, place the reinforced flatbed car in the supporting trolley to be consigned, use four jacks to lift the four corners of the trolley off the track, and arrange four Root the steel beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com