JQ900A bridge erecting machine assembly technology

A JQ900A, process technology, applied in the field of bridge erection machine assembly process, can solve the problems of poor applicability, lack of construction equipment and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

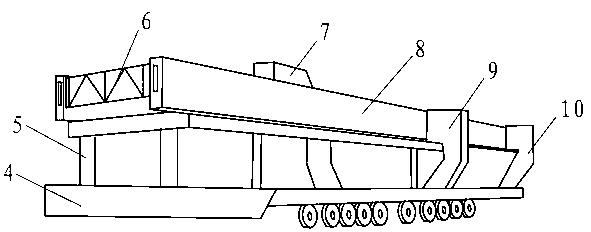

[0028] According to attached figure 1 It can be seen that the present invention specifically relates to a JQ900A bridge erecting machine assembly process, which belongs to the technical field of bridge construction.

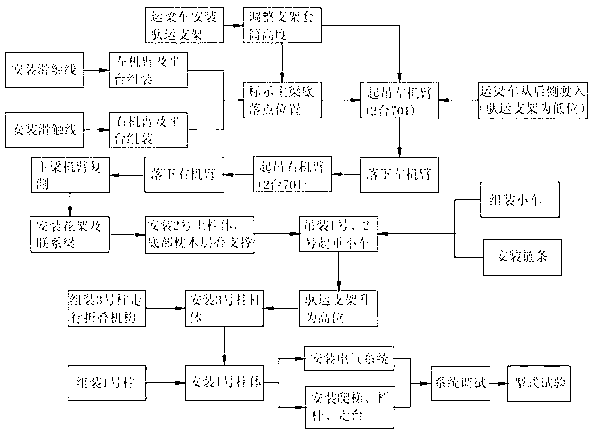

[0029] The assembly process of JQ900A bridge erecting machine is as follows:

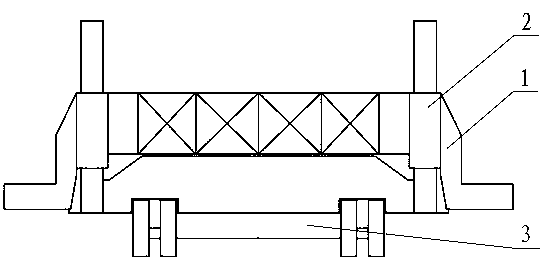

[0030] 1) According to the direction of the beam erection, first assemble the left and right main beams 8 and the supporting platform, and then install the carrying bracket 1 on the beam transporting vehicle and adjust the height through the bracket sleeve 2;

[0031] 2) Adjust the height of the support sleeve 2 so that the cross arm of the carrying support 1 is 2 meters away from the ground, that is, the lower position, and fix the support sleeve 2 with a pin;

[0032] 3) According to the structural shape and size of the main beam 8, mark the landing point position on the bottom surface of the main beam 8 and the bracket ear;

[0033] 4) Through the cooperation of two 70-ton cranes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com