Anti-abrasion tile expansion joint used for thermoelectric boiler

A technology of anti-wear tiles and expansion joints, which is applied to expansion compensation devices for pipelines, pipelines to prevent damage/wear, pipes/pipe joints/fittings, etc. It can solve the problem of adding anti-wear tiles to prevent further wear and welding of pipes Part of the problem is easy to wear, poor welding, etc., to achieve the effect of reducing welding hours, good wear resistance, and convenient processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

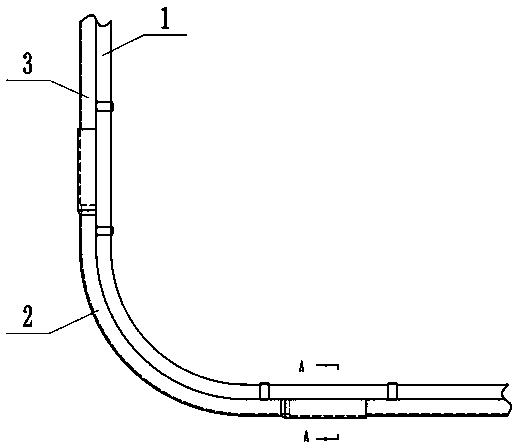

[0014] by figure 1 It is known that an anti-wear tile expansion joint for thermoelectric boilers of the present invention is composed of a heat exchange tube 1, an elbow anti-wear tile 2, a straight pipe anti-wear tile 3, and the elbow anti-wear tile 2 is fixed on the heat exchange tube 1 elbow. On the outside of the part, the straight pipe anti-friction shoe 3 is installed on the outside of the straight pipe part of the heat exchange tube 1.

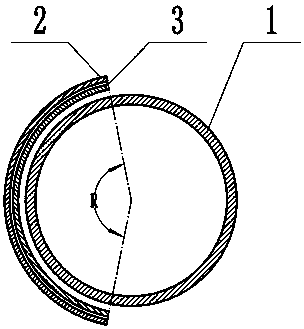

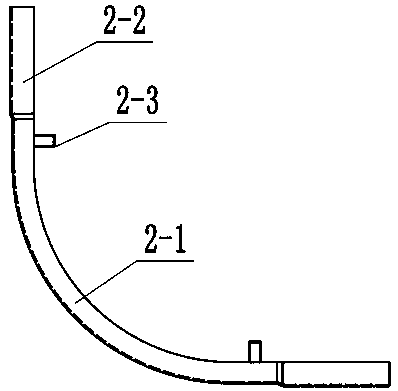

[0015] by figure 2 It is known that since the portion of the straight pipe wear-resistant tile 3 extends into the inner side of the straight shell portion 2-2 of the bent pipe wear-resistant tile 2, the inner diameter of the straight shell portion 2-2 is larger than the outer diameter 2 of the straight pipe wear tile 3 -5mm, in order to facilitate installation, the bending angle R of the bending pipe anti-wear tile 2 and straight pipe anti-wear tile 3 is 120-180 degrees, and the windward side of the heat exchange tube 1 is the outer side, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com