Novel optical fiber jumper branch curing device

A technology of curing device and optical fiber jumper, which is applied in the field of optical fiber jumper connection, can solve the problems of inability to meet the requirements of waterproof and dustproof, affecting the optical performance index of products, and deformation of heat shrinkable tubes by force, so as to achieve light weight and good mechanical performance. , the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

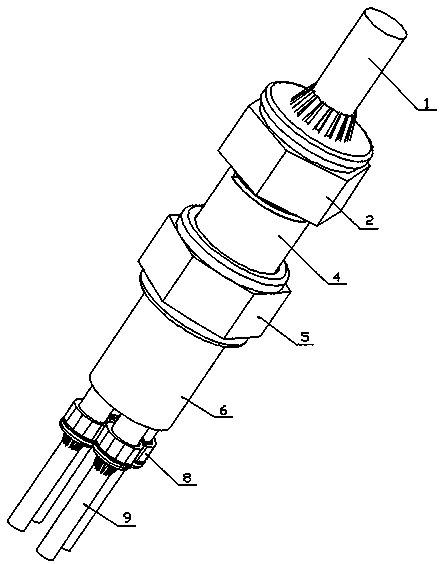

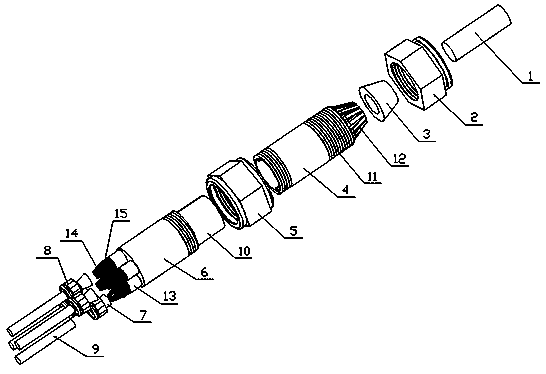

[0030] A novel fiber jumper branch curing device of the present invention includes a main cable locking mechanism for locking the main optical cable 1, an auxiliary cable locking mechanism for locking the branch optical cable 9, and a connecting main cable. The branch locking mechanism of the cable locking mechanism and the auxiliary cable locking mechanism; wherein, the main cable locking mechanism and the auxiliary cable locking mechanism are respectively provided with a sealing structure and a locking structure for sealing and locking the optical cable.

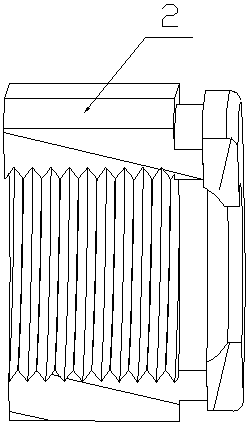

[0031] In the present invention, the main cable locking mechanism includes a main cable locking nut 2, a main cable rubber plug 3 and a main cable branch end 4; wherein, the main cable locking nut 2 and the main cable branch end 4 can be made of nylon as required. , PE, PP, PC, ABS and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com