Certified product packaging anti-counterfeiting method and system based on discontinuous bar code adhesive tape

An anti-counterfeiting system and barcode technology, applied in the fields of collaborative operation devices, structured data retrieval, instruments, etc., can solve the problems of high threshold for successful calculation and copying, and anti-counterfeiting means are easy to be counterfeited. Uniqueness, the effect of preventing tampering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

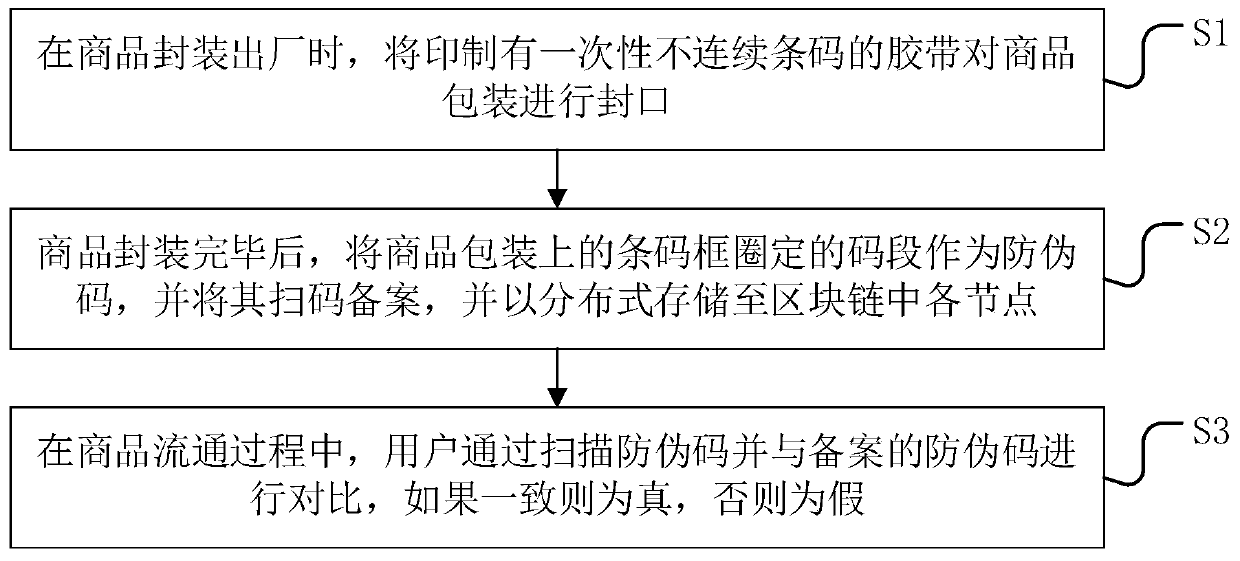

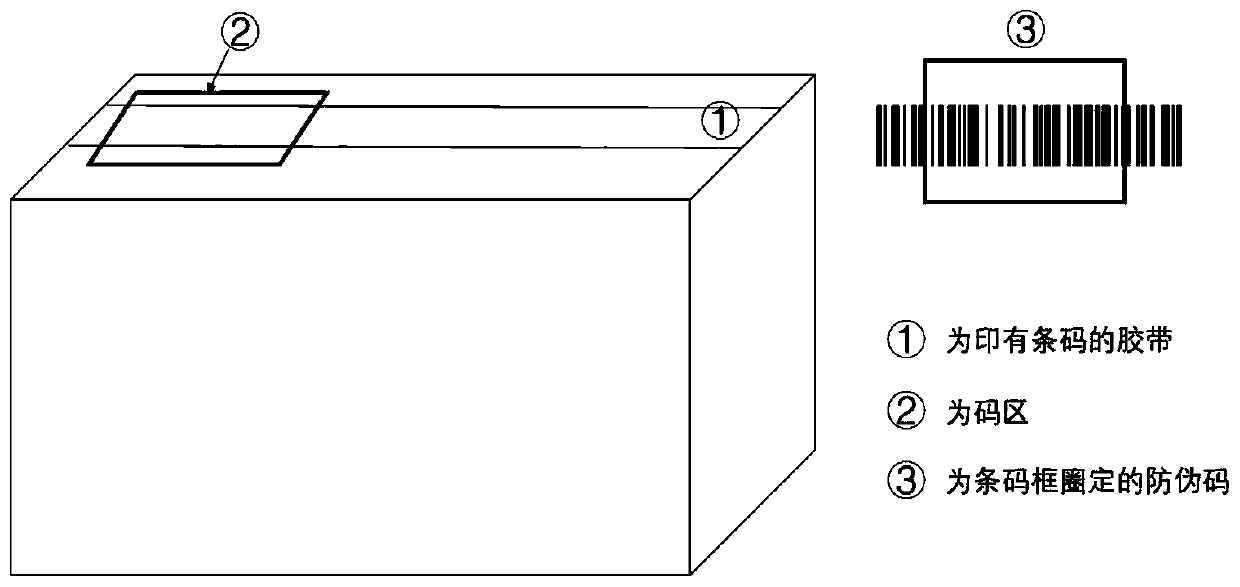

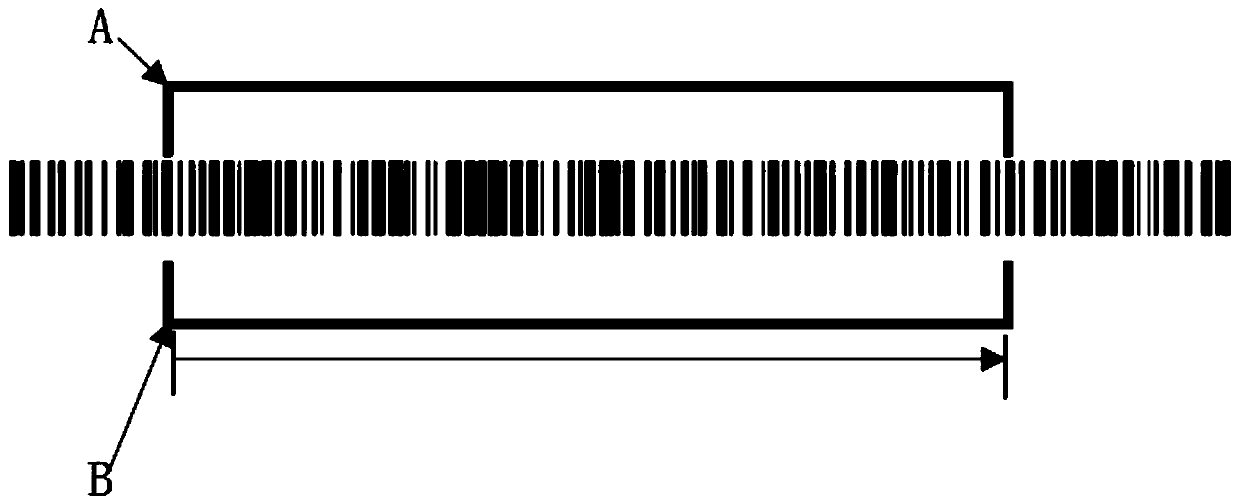

[0037] Such as figure 2 As shown, when the product is packaged and leaves the factory, the manufacturer needs to seal the tape on the seal of the product's outer package. The tape is preferably a mark-retaining tape to ensure that the tape cannot be torn off and reused. The tape prints a one-time discontinuous, non-repetitive, and regular barcode from the beginning to the end. The barcode is composed of numbers and letters. The barcodes on the tape are different to ensure the uniqueness of the anti-counterfeiting code. The characters are "3597932346264338279502878164062863452...", and there is a barcode box on the tape seal of the product outer packaging box, which is used for end consumers to verify the authenticity.

[0038] When the product is packaged, ensure that the tape covers the sealing area of the box without interruption, including but not limited to the front and back I-shaped areas, and ensure that the tape at the barcode frame does not overlap.

[0039] After...

Embodiment 2

[0045] Such as Figure 4 As shown, when the product is packaged and leaves the factory, the manufacturer needs to seal the tape on the seal of the product's outer package. The tape is preferably a mark-retaining tape to ensure that the tape cannot be torn off and reused. The tape prints a one-time discontinuous, non-repetitive, and regular barcode from the beginning to the end. The barcode is composed of numbers and letters. The barcodes on the tape are different to ensure the uniqueness of the anti-counterfeiting code. The characters are "314159265359793234626433827950287816406286...", and the barcodes on the tapes of all the outer boxes are different. The characters corresponding to the barcode of the packing tape of the minimum packaging specification for a single product are "1314535943054424567...", and the barcodes on each packing box are also different. Set up two barcode boxes at the sealing place of the tape route of the outer packing box, which are used for authenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com