A device for homogenizing direct-writing solar cell electrodes

A solar cell and electrode technology, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of limiting the photoelectric conversion efficiency of solar cells, the thickness of the silicon substrate cannot be further reduced, and the uneven surface fluctuation of the electrode grid lines, so as to improve the photoelectric conversion Efficiency, guaranteed stable progress, and good shape uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

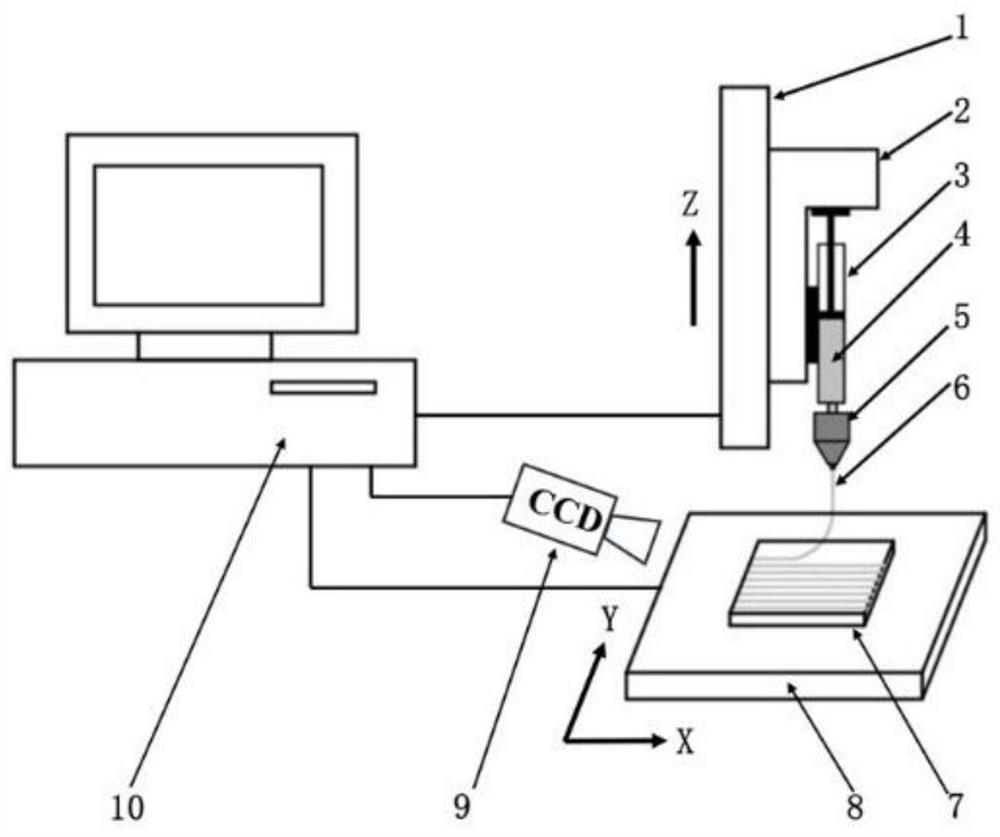

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The embodiment mainly consists of four parts: a pressure supply module, a nozzle module, a motion control module and a vision module.

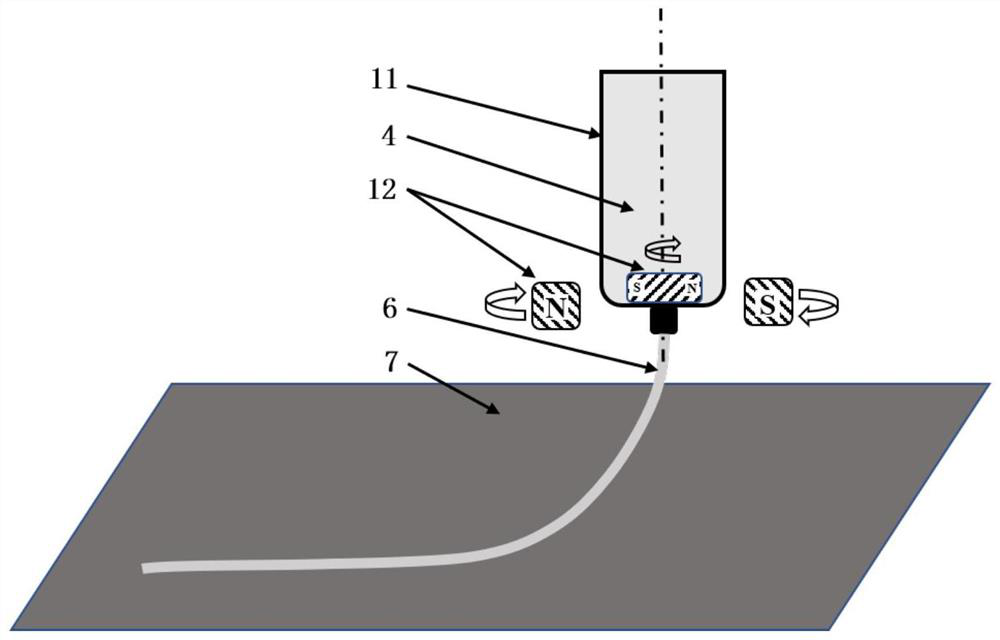

[0020] The pressure supply module includes a syringe pump 2 and an electrode slurry injection chamber 3 . The syringe pump 2 is a mechanical screw pump with a flow rate set at 10 μL / min, which is installed vertically on the Z displacement axis 1; the electrode slurry spray chamber 3 is a polyethylene sealed cylinder with electrode slurry inside 4. The tail is a pressure piston rod, and the head is a threaded structure connected with the nozzle module 5. The electrode slurry injection chamber 3 is installed on the injection pump 2, and the thrust of the injection pump 2 acts on the electrode slurry 4 in the electrode slurry injection chamber 3 through the pressure piston rod to realize pressure supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com