Stator punching piece lamination device

A stator punching and lifting device technology, applied in the field of lamination mechanism, can solve the problems of harmful workers' health and waist injury, and achieve the effect of ensuring physical health, reducing the number of times of bending, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

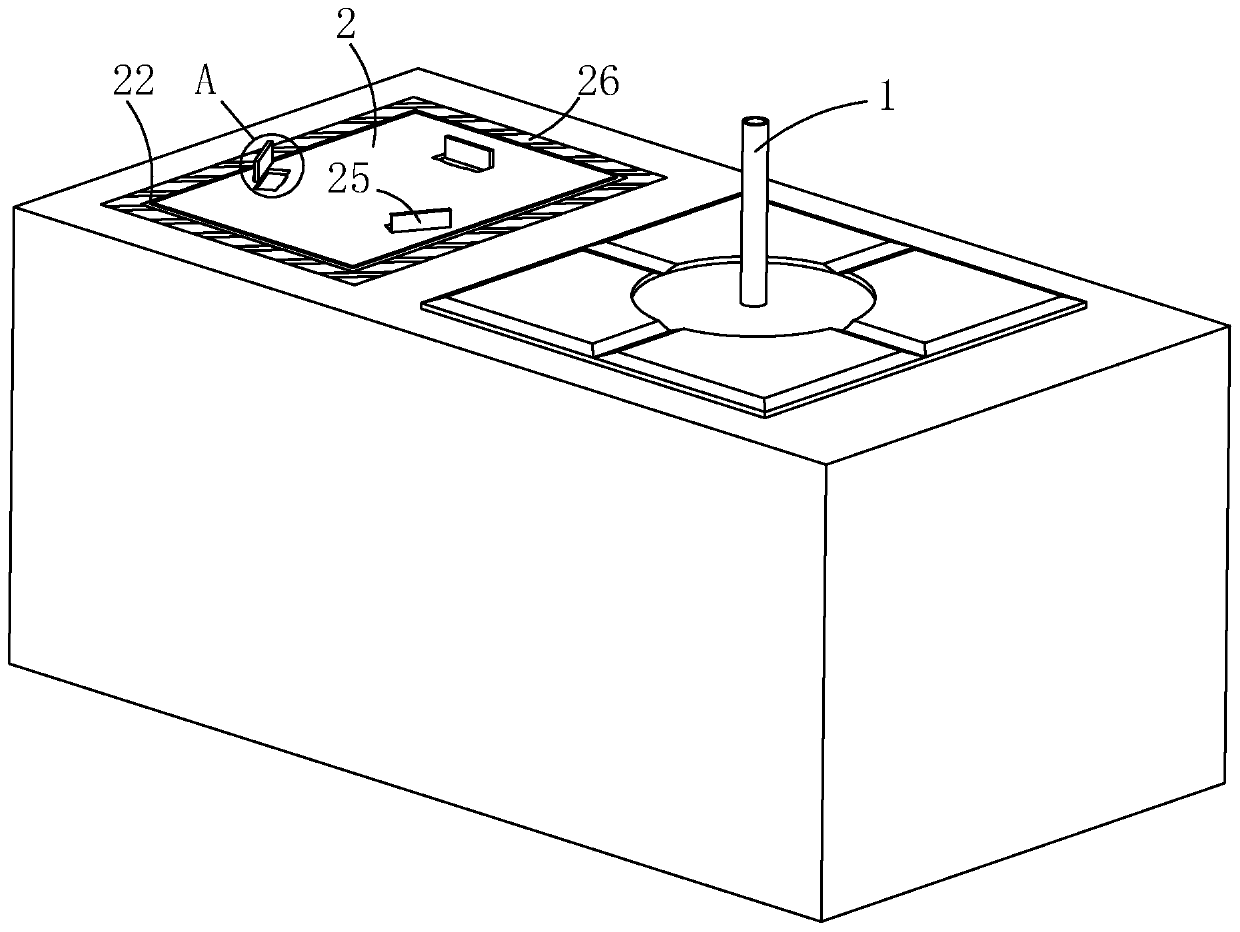

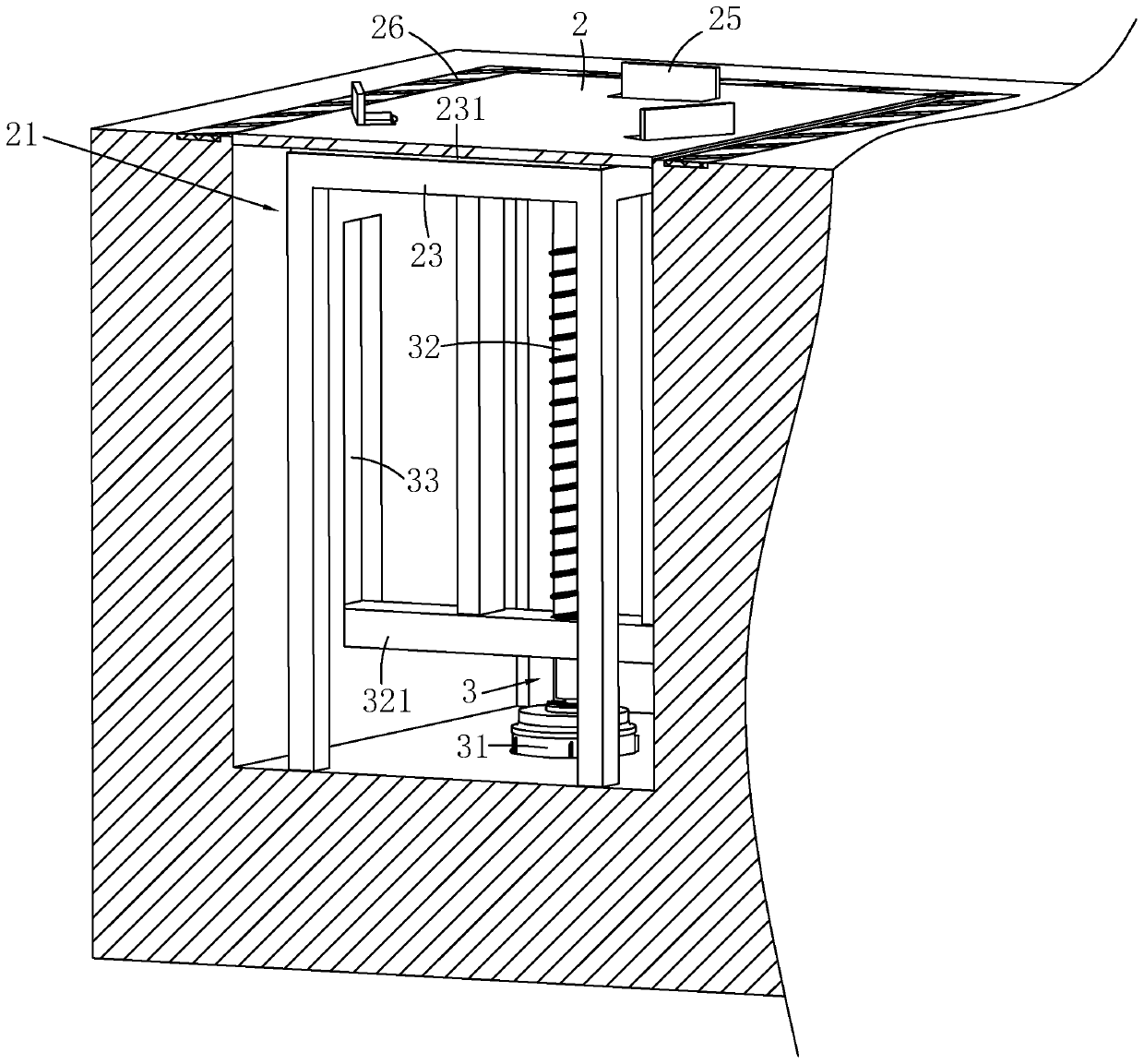

[0037] refer to figure 1 , is a stator punching lamination device disclosed in the present invention, which includes a cylindrical column 1 vertically arranged on the ground, and the side of the column 1 is provided with a placing platform 2 for placing stator punching pieces, and the ground There is a cavity 21 corresponding to the placement platform 2 on the upper side, wherein the side with the largest surface area of the placement platform 2 is equal to the surface area of the mouth of the cavity 21, and a warning line 26 is pasted around the cavity 21 on the ground around the mouth of the cavity 21 , warning line 26 is made of yellow and black reflective material.

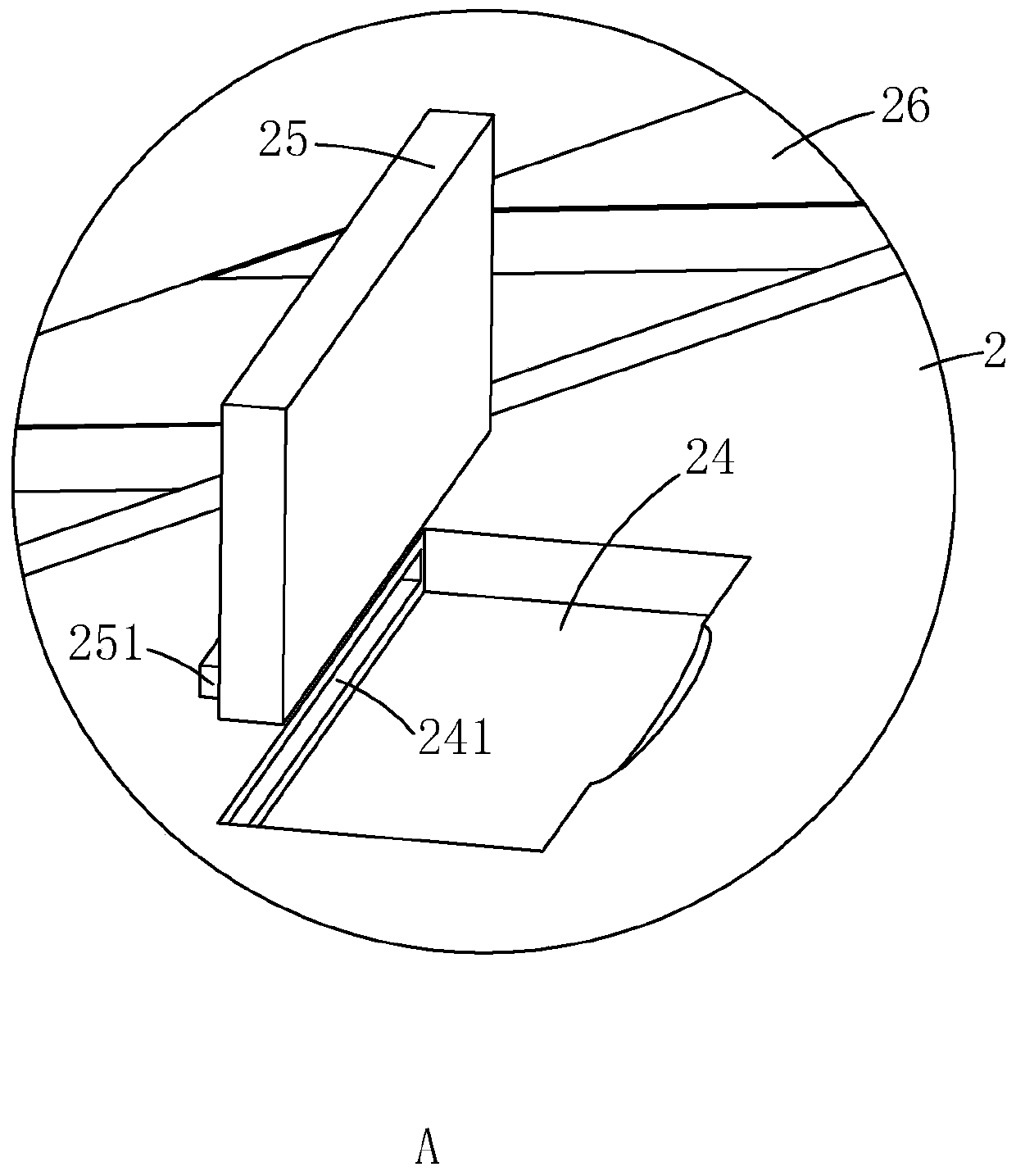

[0038] refer to figure 1 and figure 2 , the upper surface of the placement table 2 is provided with grooves 24, and there are at least three grooves 24. In this embodiment, there are three grooves 24, and the connecting line between two adjacent grooves 24 is An equilateral triangle is arranged; each g...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 mainly lies in: Figure 4 As shown, the lifting device 3 includes a cylinder 34 vertically arranged on the bottom wall of the cavity 21 , and the piston rod of the cylinder 34 is fixedly connected to the bottom of the placing platform 2 . A right-angled triangle support plate 322 is provided between the piston rod of the cylinder 34 and the placement table 2, wherein one right-angled side of the support plate 322 is connected with the bottom of the placement platform 2, and the other right-angled side is connected with the piston rod of the cylinder 34.

[0046] The implementation principle of this embodiment is: when in use, turn over the limiting plate 25, turn the limiting plate 25 until the block 251 is engaged in the slot 241, at this time the limiting plate 25 will protrude from the groove 24 and remain vertical In this way, the stacked stator punches are placed between the limit plates 25, the limit plate 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com