Air filtering device and control method for air filtering device

An air filter device and control method technology, applied in the field of air purification, can solve the problems of inability to filter excessive pollutants, affecting the filtration rate of excessive pollutants, inability to adjust the filter gap of the filter screen, etc., to achieve stable and reliable transmission accuracy and occupy less space. , The effect of high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

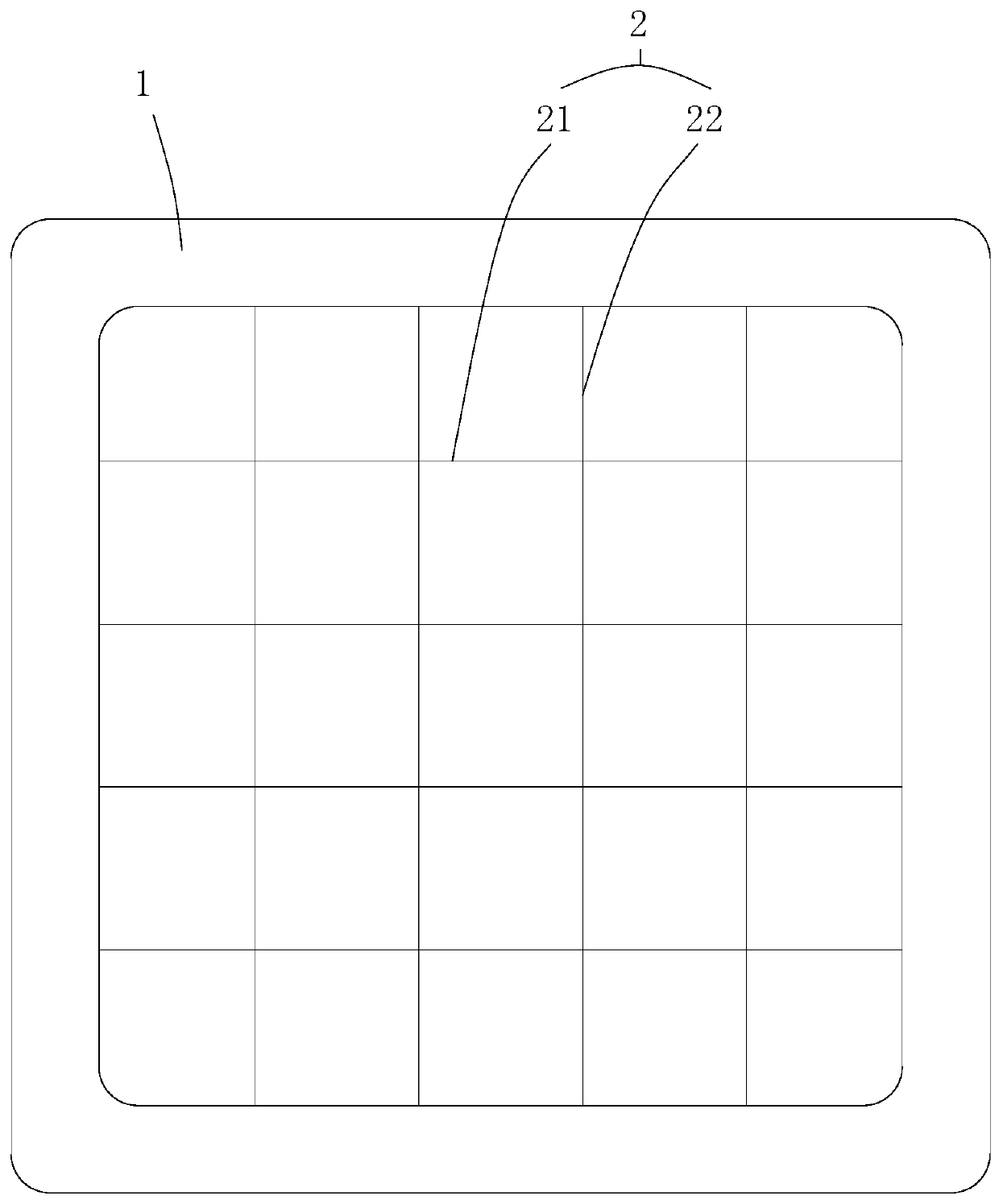

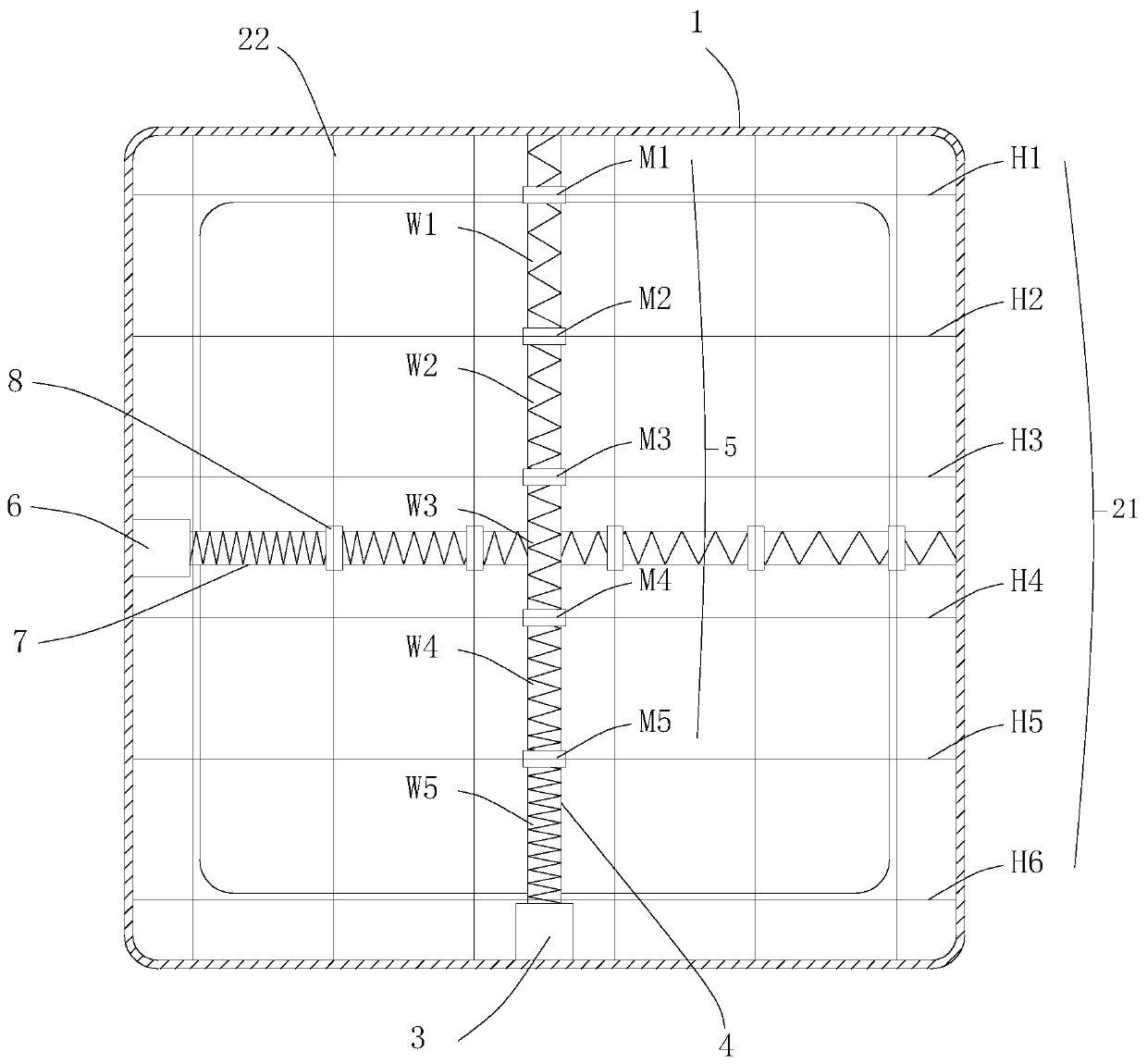

[0036] Such as figure 2 As shown, the first driving member is a first driving motor 3, the first transmission member includes a first lead screw 4 and a plurality of first nuts 5 screwed with the first lead screw 4, the first lead screw 4 and the first drive The output shaft of the motor 3 is connected, and the first nut 5 is connected with the corresponding horizontal wire 21. The first drive motor 3 can drive the first screw 4 to rotate to drive the plurality of first nuts 5 to move and thus drive the corresponding horizontal wire 21 vertically. The first lead screw 4 is configured to drive the plurality of first nuts 5 to move proportionally and thus drive the corresponding horizontal wires 21 to move vertically in proportion. In a possible situation, the filter screen 2 includes 6 transverse wires 21 ( figure 2 Shown H1, H2, H3, H4, H5 and H6), the first transmission member includes 5 first nuts 5 ( figure 2 M1, M2, M3, M4 and M5 shown), where M1 is connected to H1, M...

Embodiment 2

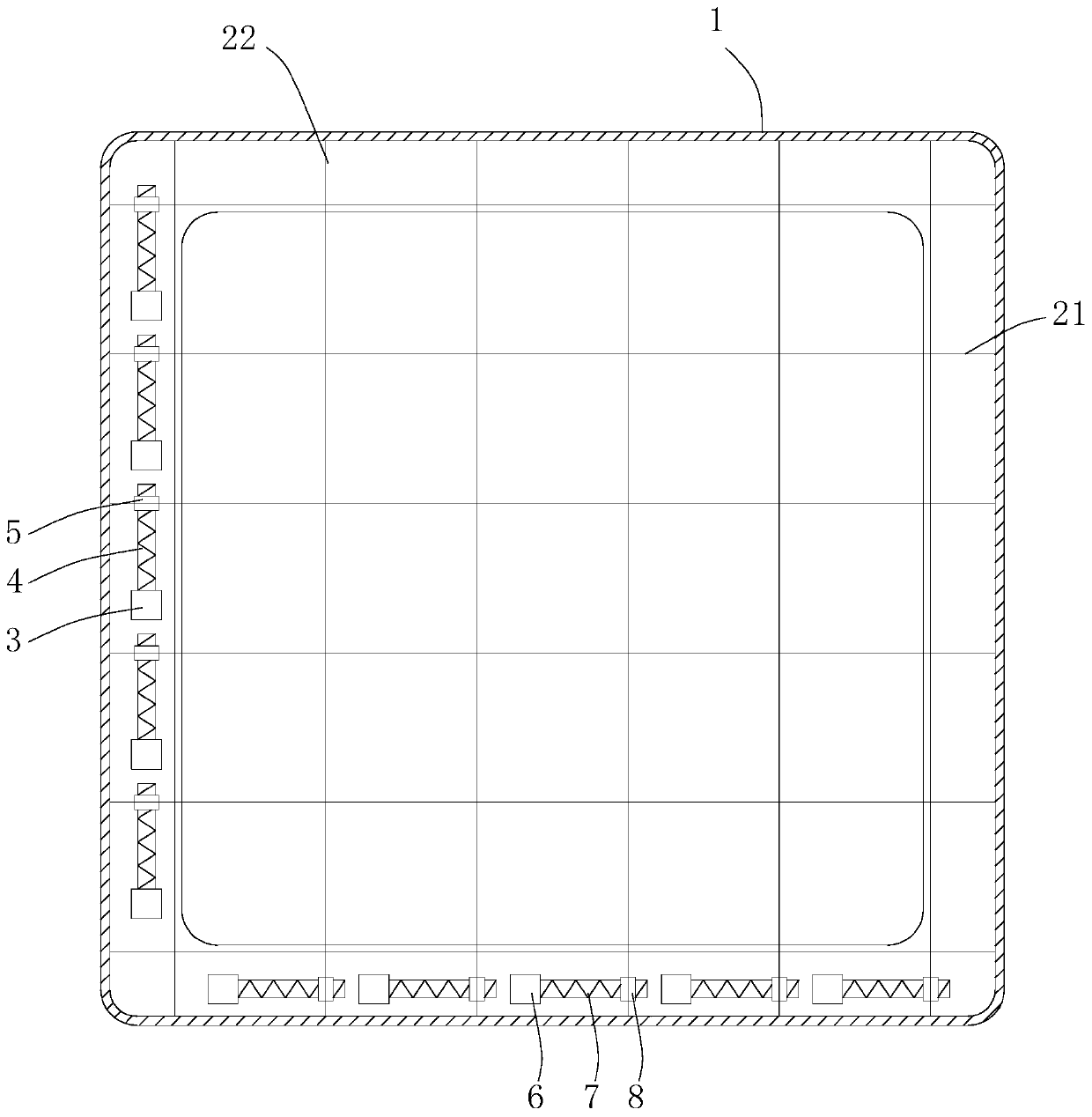

[0039] Such as image 3 As shown, the first driving member includes a plurality of first driving motors 3, the first transmission member includes a plurality of first lead screws 4 and first nuts 5 screwed to each other, and the first lead screws 4 and corresponding first drive motors 3, the first nut 5 is connected with the corresponding horizontal wire 21, the first drive motor 3 can drive the corresponding first lead screw 4 to rotate to drive the corresponding first nut 5 to move and thus drive the corresponding horizontal wire 21 Move vertically, the second drive member includes a plurality of second drive motors 6, the second transmission member includes a plurality of second lead screws 7 and second nuts 8 that are screwed to each other, the second lead screws 7 and the corresponding second drive The output shaft of the motor 6 is connected, the second nut 8 is connected with the corresponding vertical wire 22, and the second driving motor 6 can drive the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com