Vacuum pumping buffer structure for die-casting mold

A buffer structure and vacuum pumping technology, which is applied in the field of vacuum pumping of die-casting molds, can solve the problems of molds not being able to produce normally, vacuum valves being blocked, aluminum liquid entering the vacuum valves, etc., to reduce mold costs, avoid damage to vacuum valves, Improve the effect of the cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

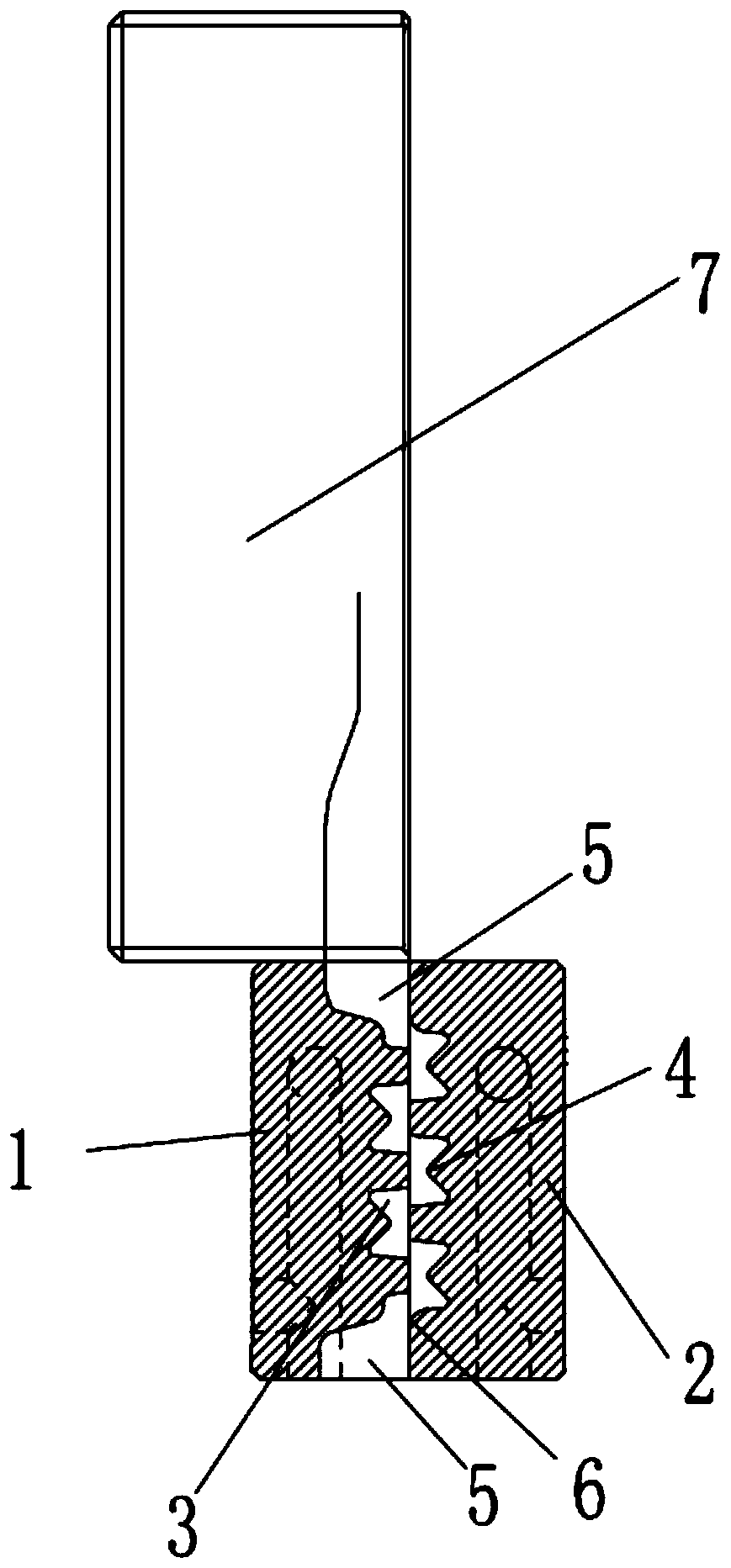

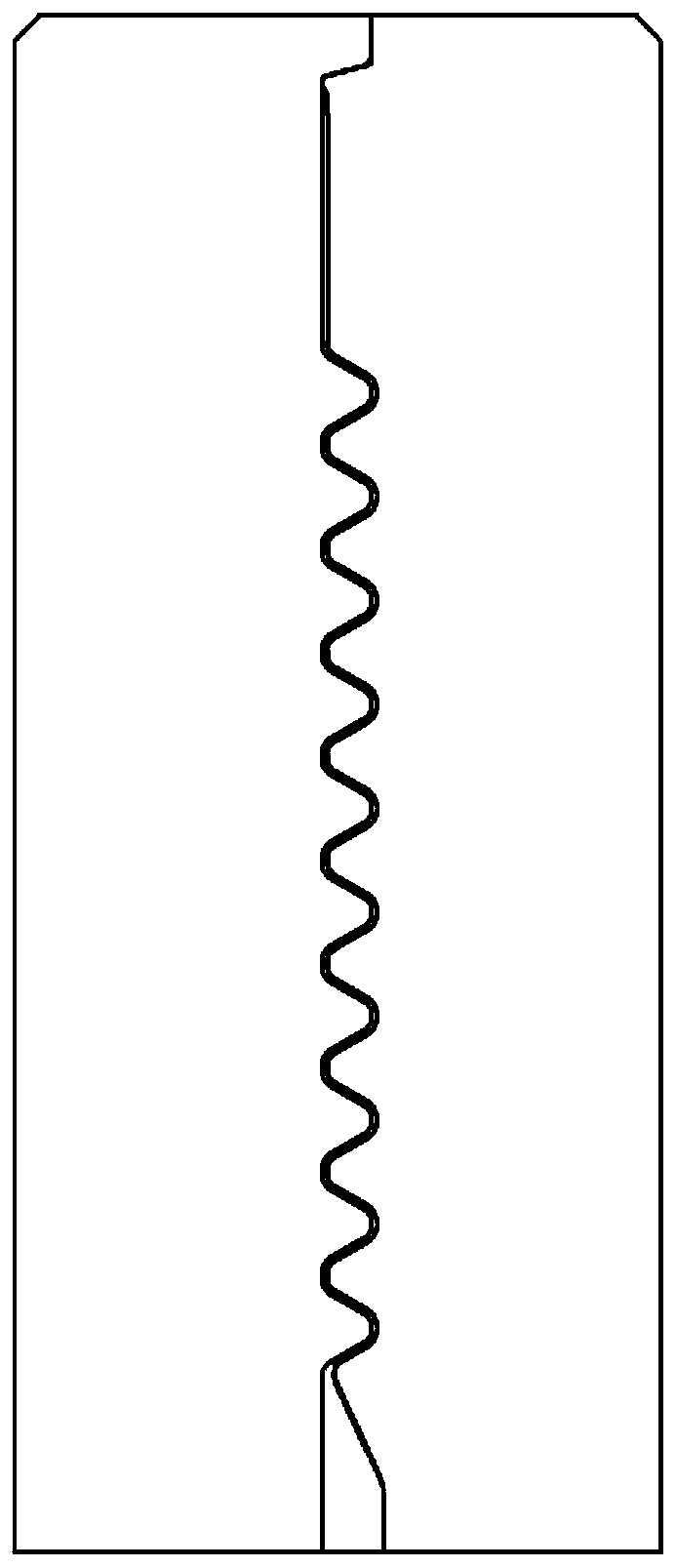

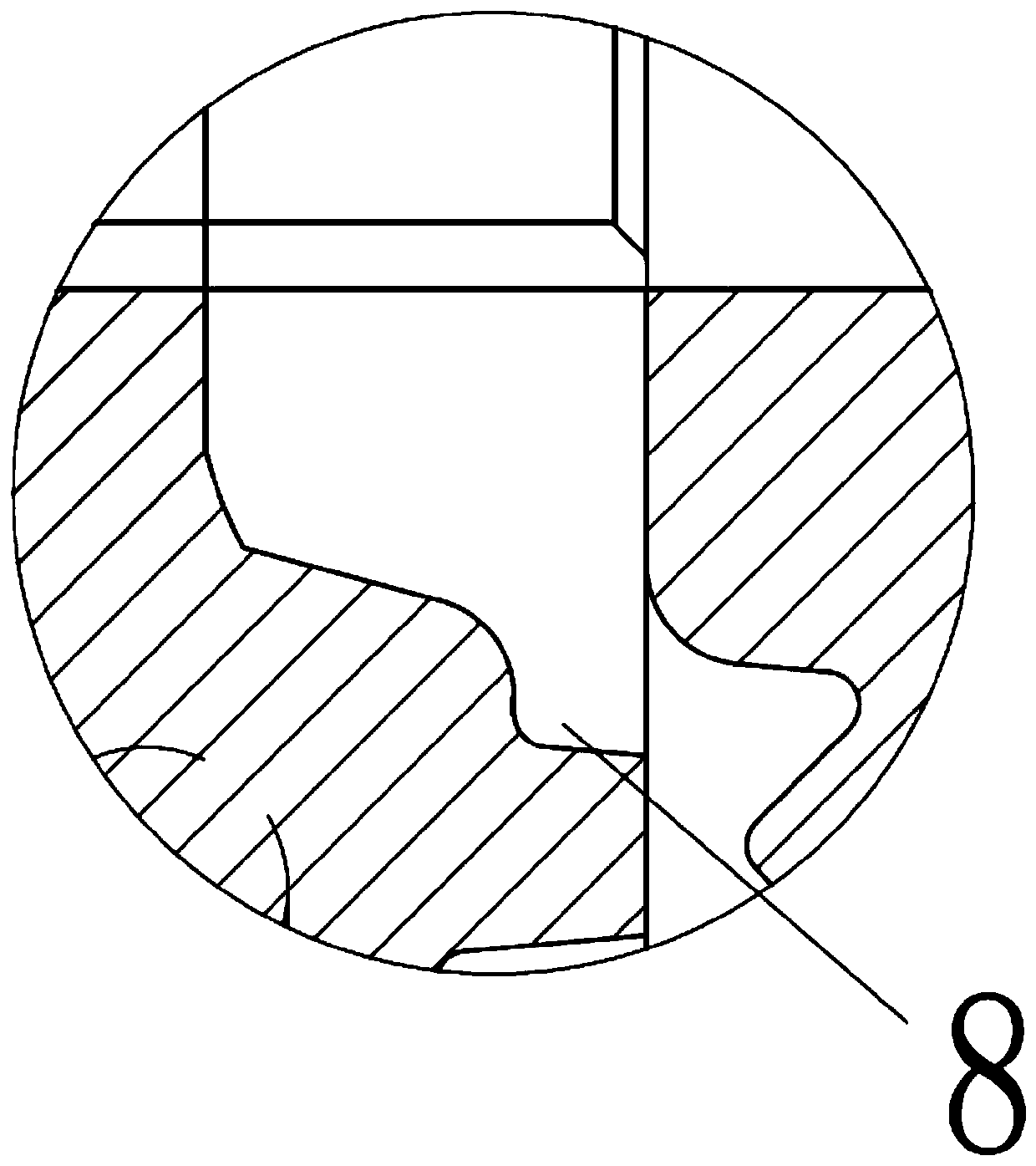

[0027] During the production process, the vacuum valve is connected to the upper buffer block 2 and the lower buffer block 1 through the vacuum valve connecting block 7. When working, the vacuum valve is activated to extract the air in the mold cavity, thereby increasing the injection speed of the aluminum liquid. Simultaneously start the cooling pipes in the upper buffer block 2 and the lower buffer block 1. When the aluminum liquid fills the mold cavity, it will enter the buffer tank 3 between the upper buffer block 2 and the lower buffer block 1. The rectangular structure of the buffer protrusion 4 and the buffer tank 3 itself reduces the kinetic energy of the molten aluminum after multiple collisions, and at the same time due to the cooling pipes in the upper buffer block 2 and the lower buffer block 1, the upper buffer block 2 and the lower buffer block The liquid aluminum in 1 is cooled, and the part is sealed to prevent the liquid aluminum from being directly sucked by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com