Automatic hand-eye calibration method and device for optimal calibration point selection and error automatic measurement

A hand-eye calibration and calibration point technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of decreased accuracy, the inability to guarantee the solution of the collected points, and the inconvenience of calibration boards or cameras.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

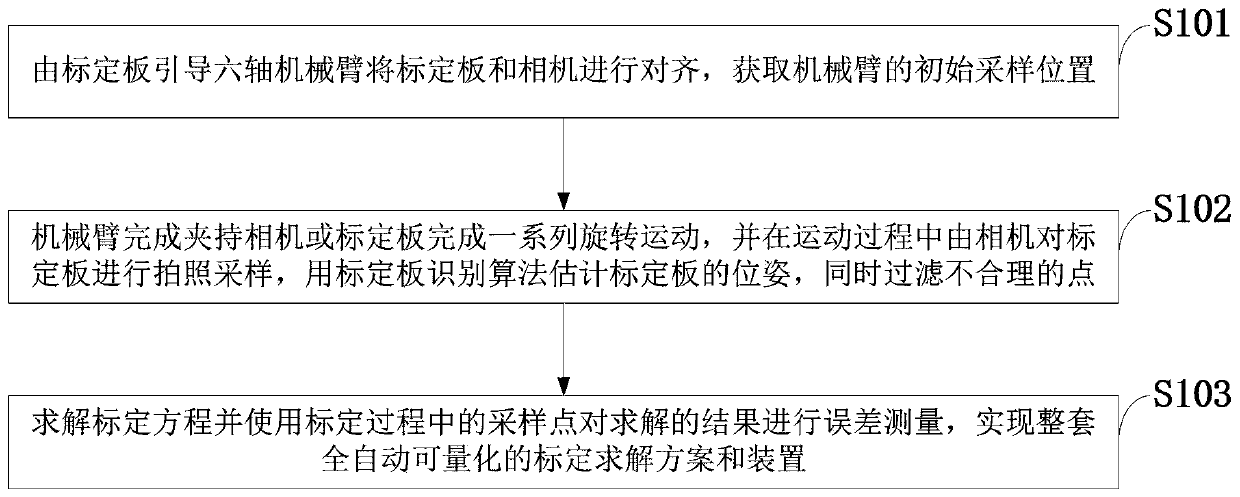

[0291] (1) Eye-in-hand one-click calibration test on the sawyer robot:

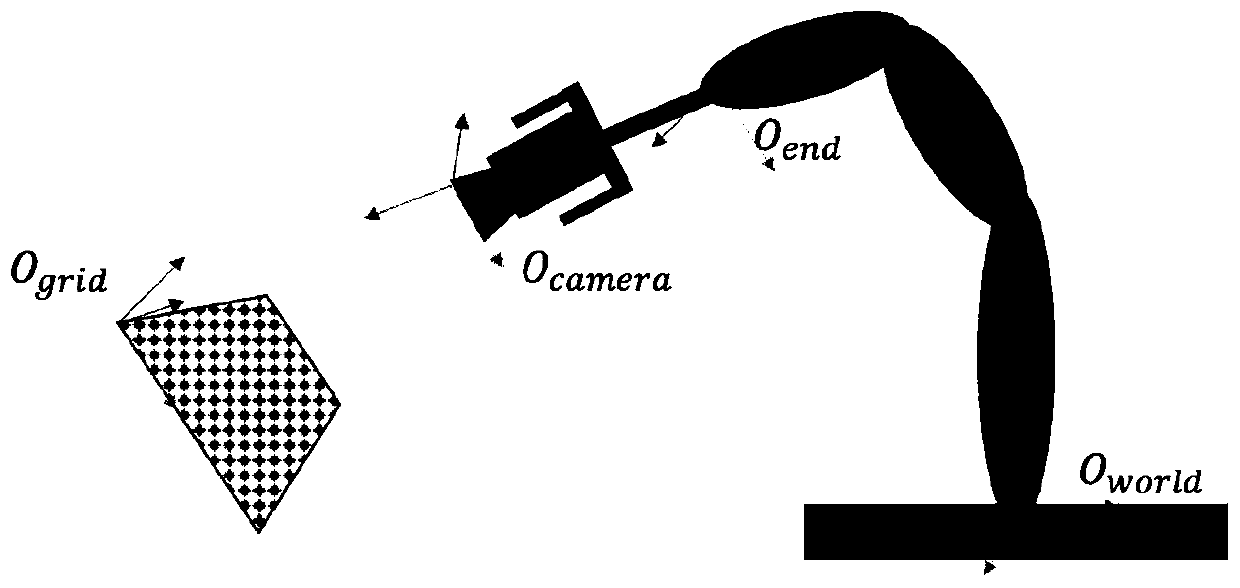

[0292] a) The robot holds the camera and moves around itself to detect whether there is a calibration plate around (such as Figure 11 shown).

[0293] b) The camera detects the existence of the calibration plate, and the robot holds the camera and moves in different directions to estimate the orientation of the calibration plate in the robot coordinate system (such as Figure 12 shown).

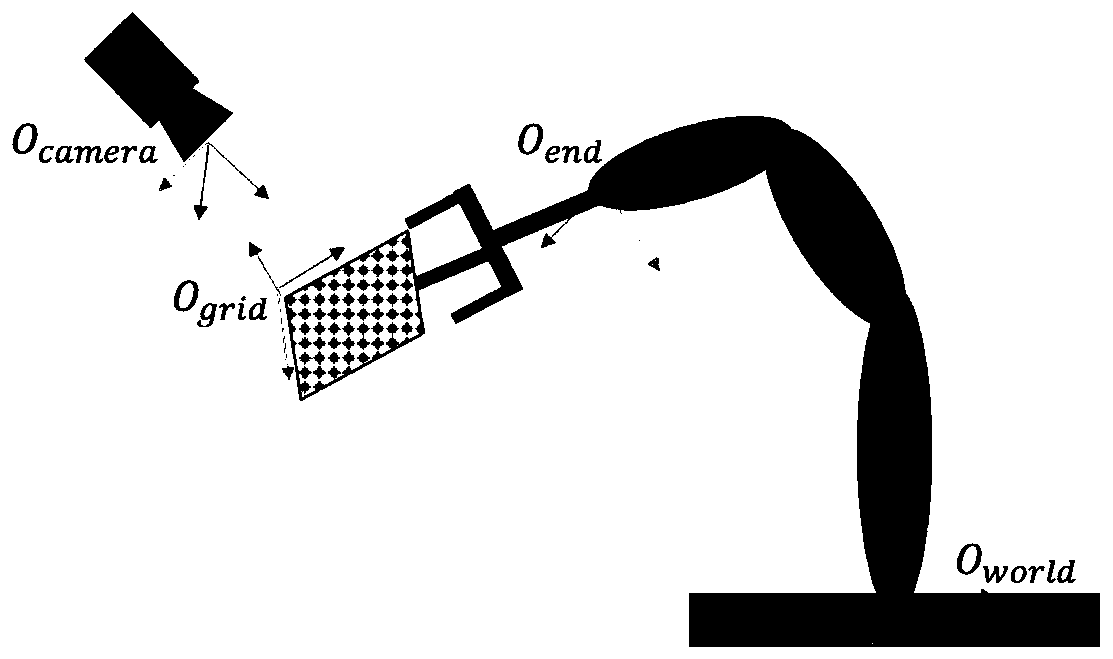

[0294] c) The robot estimates the position of the calibration plate, and at this time the end of the mechanical arm has moved directly above the calibration plate (such as Figure 13 shown).

[0295] d) The robot takes the estimated position of the calibration plate as the center, rotates and samples the calibration plate, and records the position of the end of the mechanical arm in the camera coordinate system (such as Figure 14 shown).

[0296] e) Solving the calibration equation, the data collected during the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com