Full-automatic closed sampling system for reaction kettle

A sampling system and reactor technology, applied in sampling, sampling device, general control system, etc., can solve problems such as explosion danger, operator injury, danger, etc., and achieve the effects of large-capacity sampling, rational setting and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

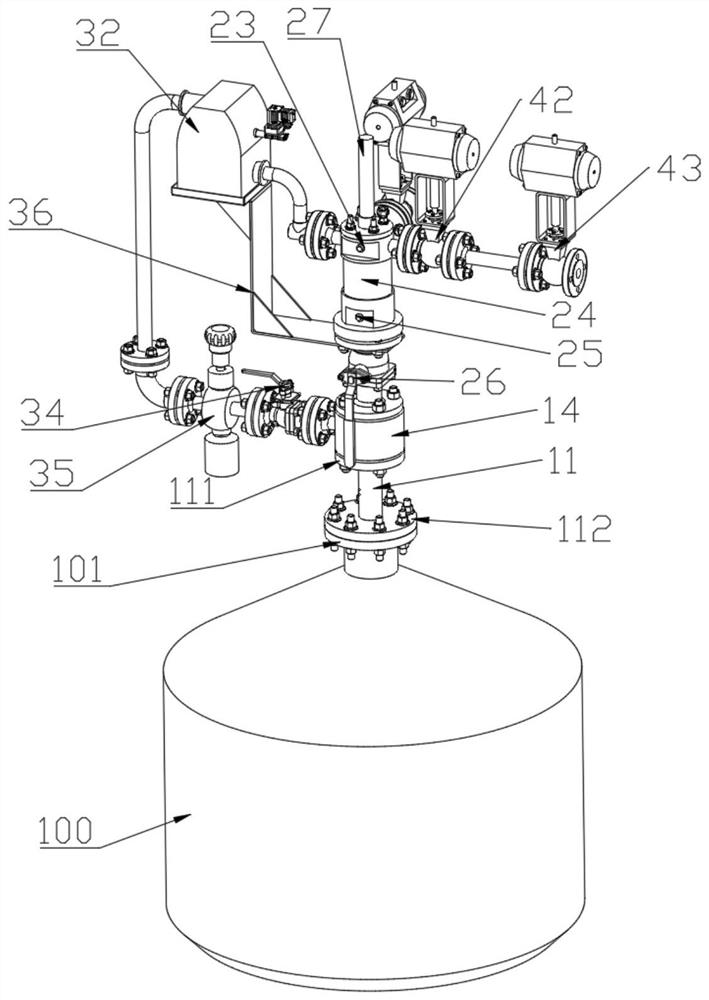

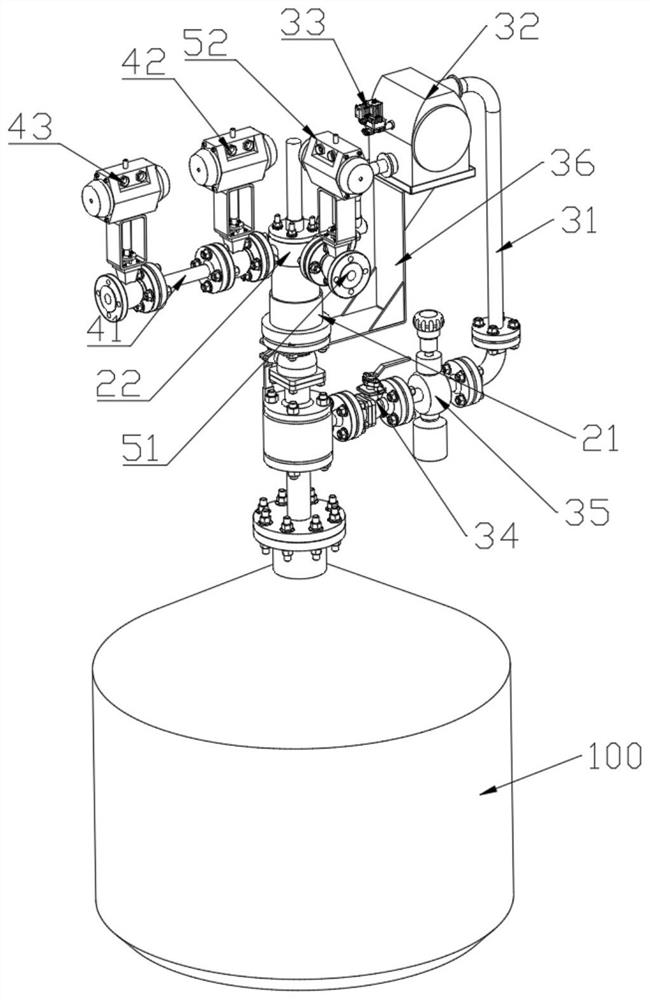

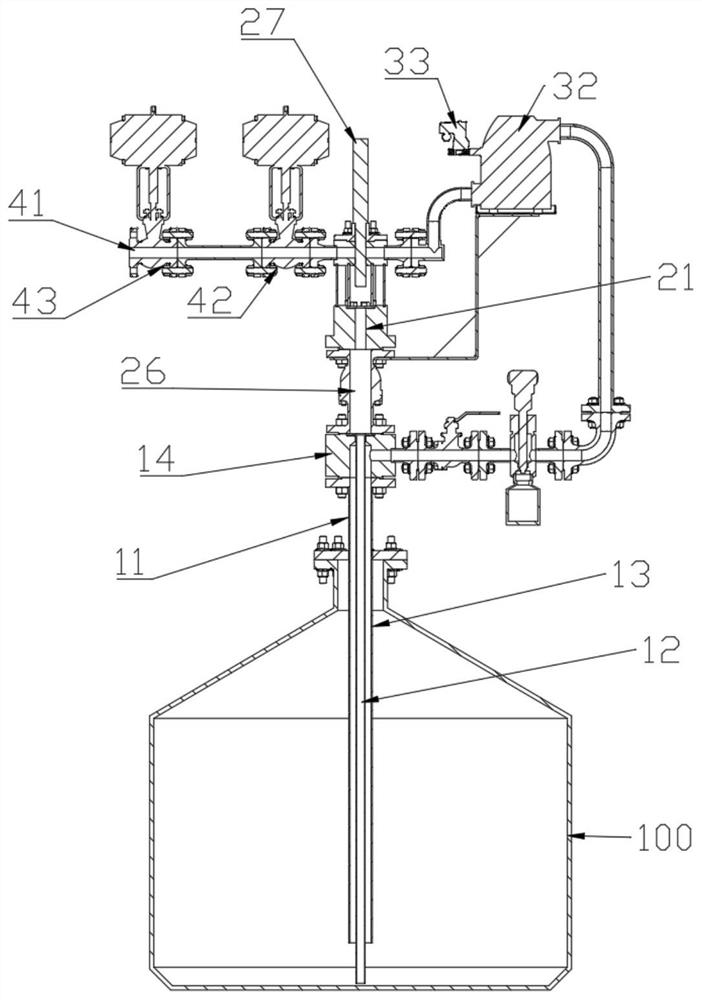

[0041] refer to Figure 1-3 , is a kind of fully automatic reaction kettle airtight sampling system according to the present invention, which mainly includes a material suction component, a liquid level monitoring component, a cycle sampling component, a vacuum adsorption component, a nitrogen purging component, a pH value measurement component and a PLC control component, Each will be described in detail below.

[0042] Wherein, the material suction assembly has a connecting pipe 11 and a suction sleeve 13 which is arranged in it and extends from its lower end. The suction sleeve 13 is provided with a suction pipe 12, and the lower end of the connection pipe 11 is The nozzle is sealingly connected with the upper nozzle of the reactor 100 to be sampled, and the upper nozzle of the connecting pipe 11 is sealed and connected with the lower in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com