Sampling device and sampling method for anhydrous hydrogen fluoride

An anhydrous hydrogen fluoride and sampling device technology, applied in the field of analytical chemistry, can solve the problems of increased cleaning difficulty, corrosion, inconvenient safe disposal, etc., and achieve the effects of reducing sampling cost, improving sampling efficiency, and ensuring authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

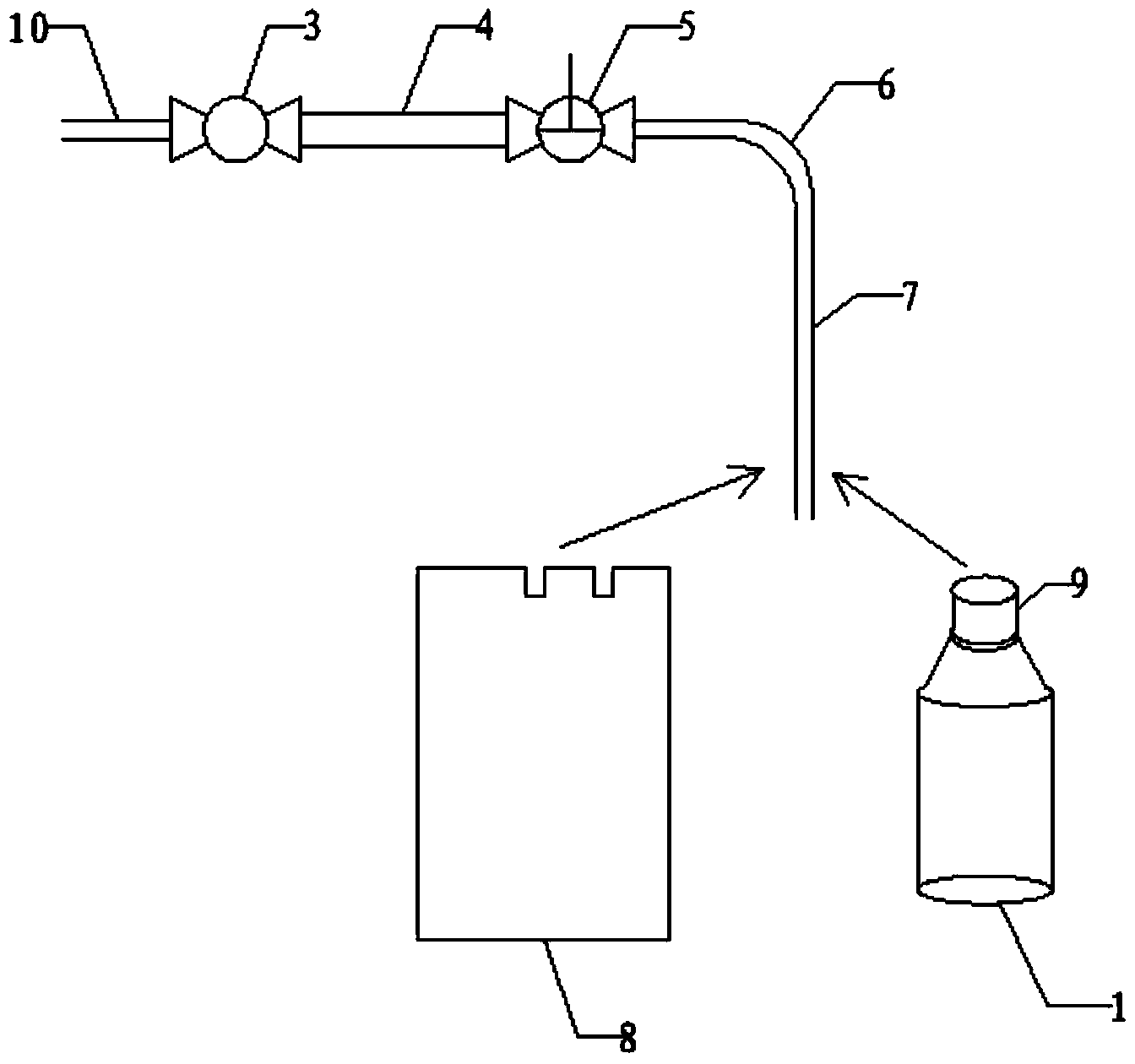

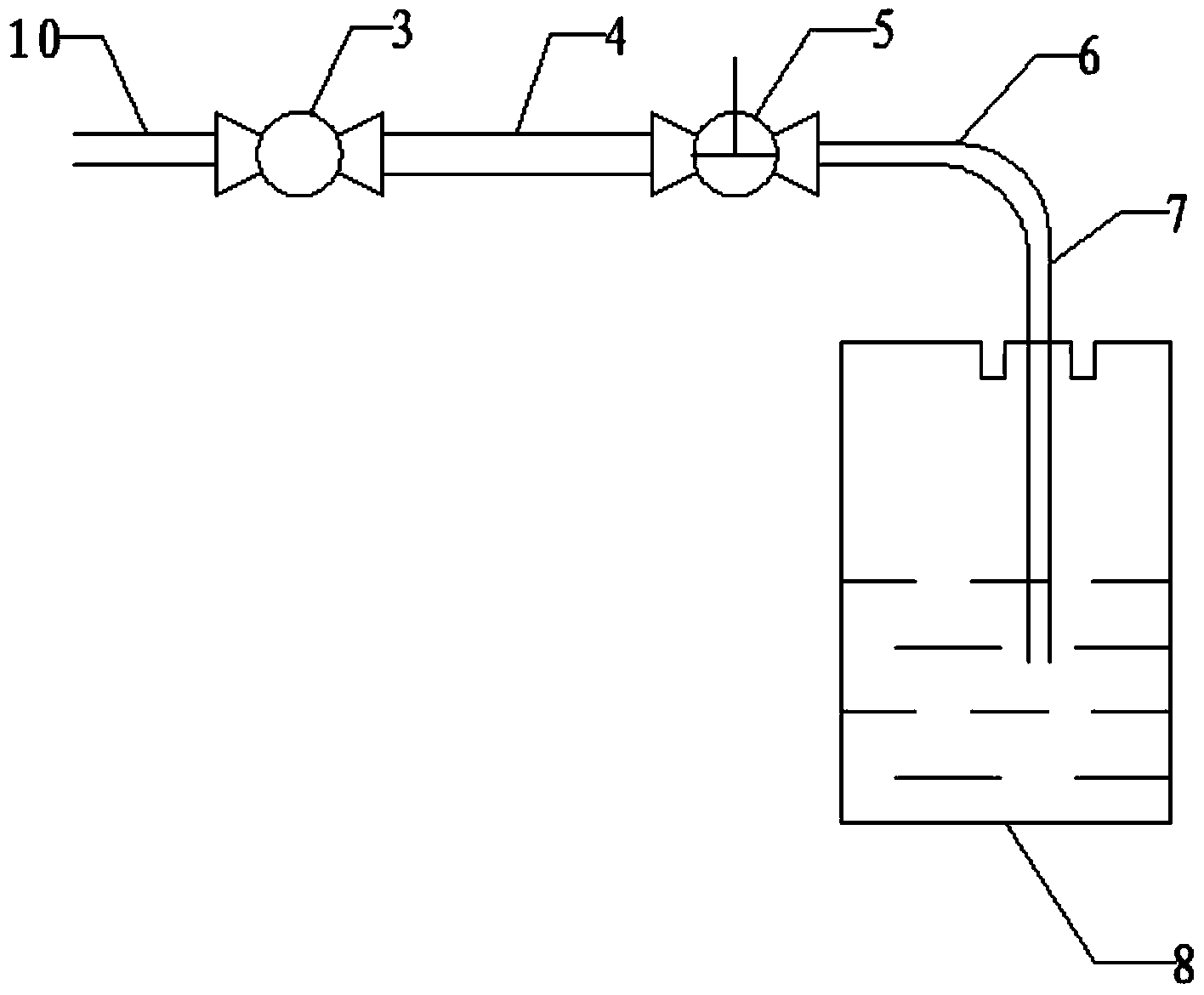

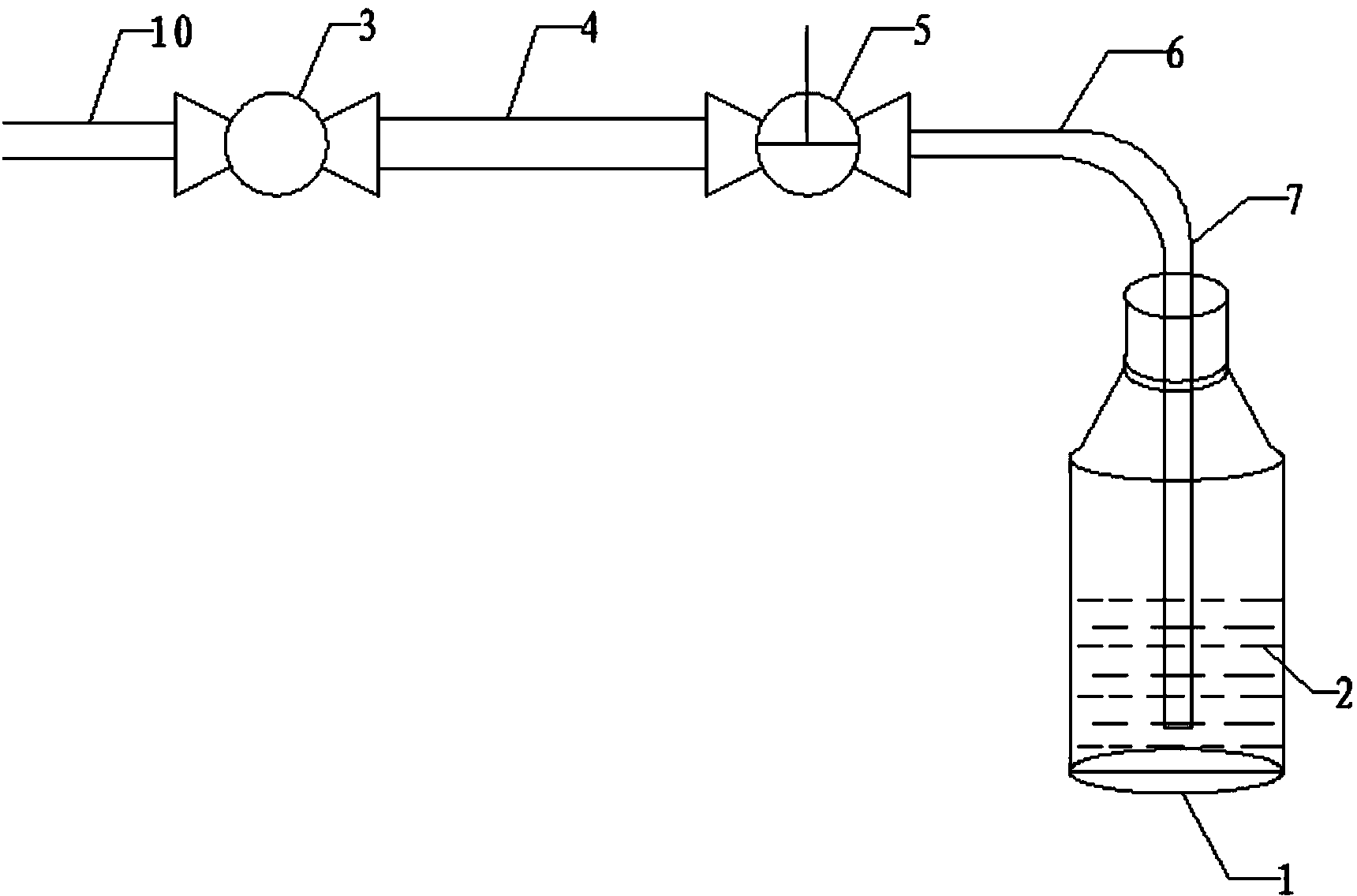

[0069] see Figure 5 As shown, the anhydrous hydrogen fluoride sampling device of the present embodiment includes an acid inlet pipe 1', a ball valve 2', a large and small head reducing diameter 3', a 1 / 4 inch pipe 4', a 1 / 4 inch PFA ball valve 5', with The 1 / 4 inch F46 pipe 6' of the bottle cap, the waste bucket 7', the sampling bottle 8', the anti-fouling bottle 9' and the cooling tank 10', the acid inlet pipe 1', the ball valve 2', the reducing head and the small head 3', 1 / 4 inch pipe 4', 1 / 4 inch PFA ball valve 5' and 1 / 4 inch F46 pipe 6' with bottle cap are connected in sequence to form a sampling pipeline, and the inlet end of the acid inlet pipe 1' For accessing the anhydrous hydrogen fluoride to be sampled, the outlet end of the 1 / 4 inch F46 tube 6' with a bottle cap is connected to the waste bucket 7', the sampling bottle 8' or the antifouling bottle 9', the The sampling bottle 8' is placed in the cooling tank 10'.

[0070] In the above embodiment, the diameter of ...

Embodiment 2

[0078] see Figure 9As shown, the anhydrous hydrogen fluoride sampling device of the present embodiment includes an acid inlet pipe 1', a ball valve 2', a large and small head reducing diameter 3', a 1 / 4 inch pipe 4', a 1 / 4 inch PFA ball valve 5', with 1 / 4 inch F46 pipe 6' of bottle cap, waste discharge barrel 7', sampling bottle 8', anti-fouling bottle 9', cooling tank 10', waste discharge valve 12' and waste discharge pipe 13', the acid inlet Pipe 1', ball valve 2', reducing head diameter 3', 1 / 4 inch pipe 4', 1 / 4 inch PFA ball valve 5' and 1 / 4 inch F46 pipe 6' with bottle cap are connected in sequence, the The waste discharge valve 12' and the waste discharge pipe 13' are sequentially connected to the 1 / 4 inch pipe 4' to form a waste discharge branch, the waste discharge valve 12' is a 1 / 4 inch PFA ball valve, and the waste discharge pipe 13' is a 1 / 4 inch F46 pipe, the inlet end of the acid inlet pipe 1' is used to access the anhydrous hydrogen fluoride to be sampled, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com