Vortex mixer for three phases

A mixer and three-phase technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sewage treatment, etc., can solve the problems of low floc formation efficiency, uneven mixing of bubbles, etc., and reduce equipment investment and running cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

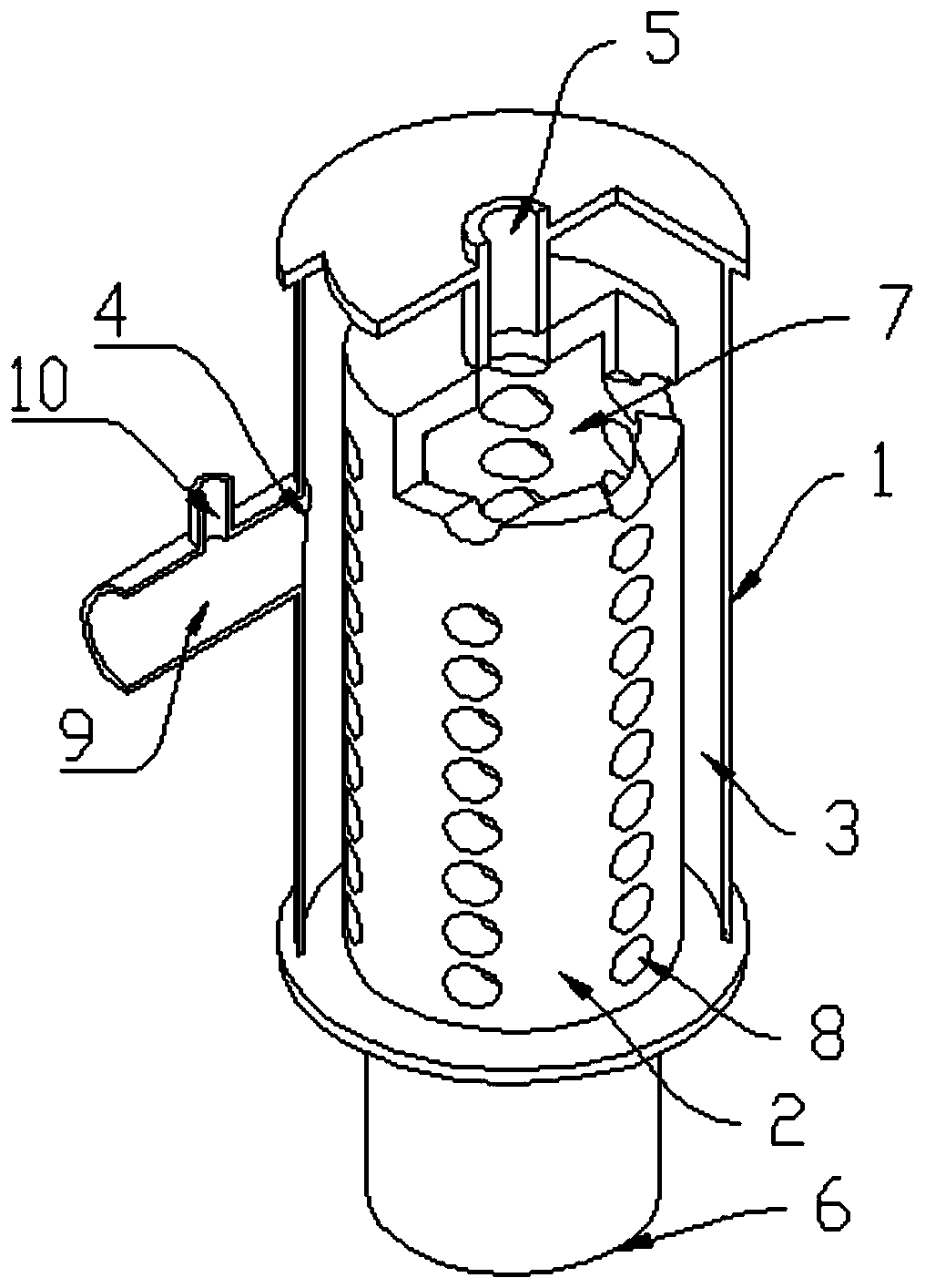

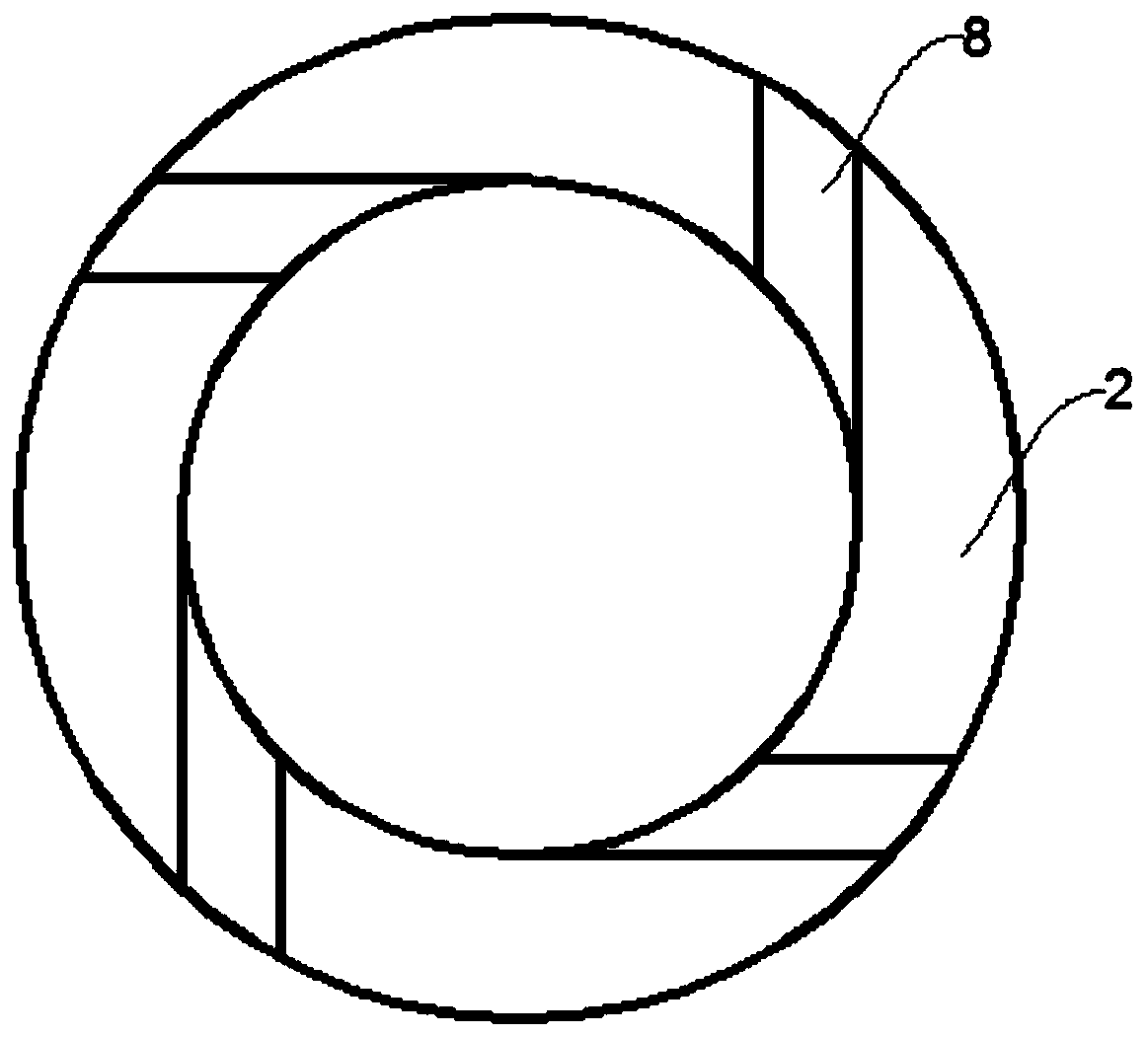

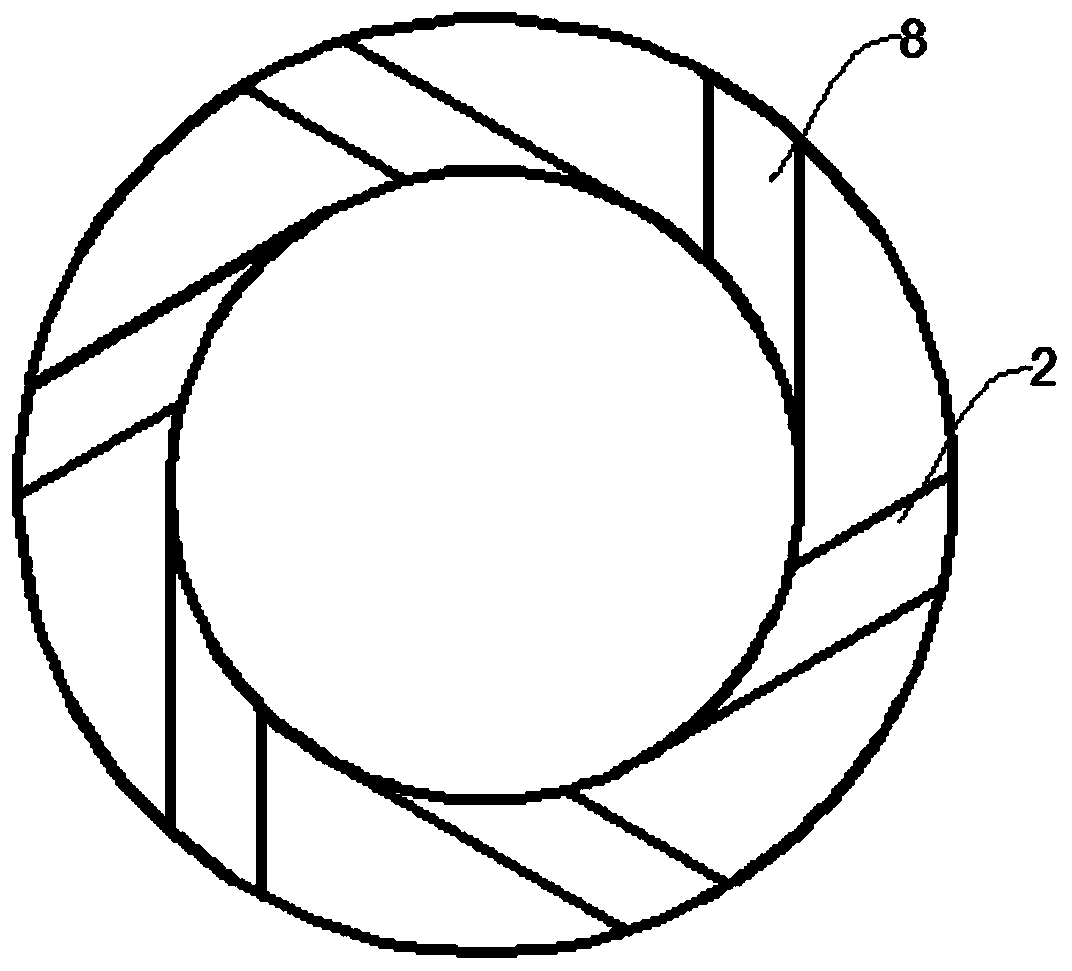

[0031] During wastewater operation, use a high-pressure water inlet pump to flow the sewage from the sewage delivery pipe through the water inlet 4 into the annular channel 3 of the three-phase mixer, and form a vortex therein. Then, the sewage is dispersed through the through hole 8 under the action of water pressure, and is divided into fine streams and flows into the mixing chamber 7 . At the same time, the compressed air is delivered to the mixing chamber 7 through the air inlet 5, where it is directly dissolved in the influent sewage. During the whole process, the chemical agent is directly added to the sewage through the dosing port 10, and enters the mixing chamber 7 along with the sewage, where the three-phase mixing of the chemical agent, the polluted particles, water and gas is completed. Since there is an included angle between the axis of the through hole 8 and the tangent of the inner cylinder, a vortex will be formed when the nozzle enters the mixing chamber. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com