Device for detecting complex profile displacement in narrow and small space, and method for detecting displacement

A technology with complex shapes and narrow spaces, which is applied in the field of detection of misalignment, can solve the problems of light incident angle limitation, sample paste cannot be reused, laser scanning cost is high, etc., achieve low manufacturing cost, realize online measurement, and facilitate workers The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

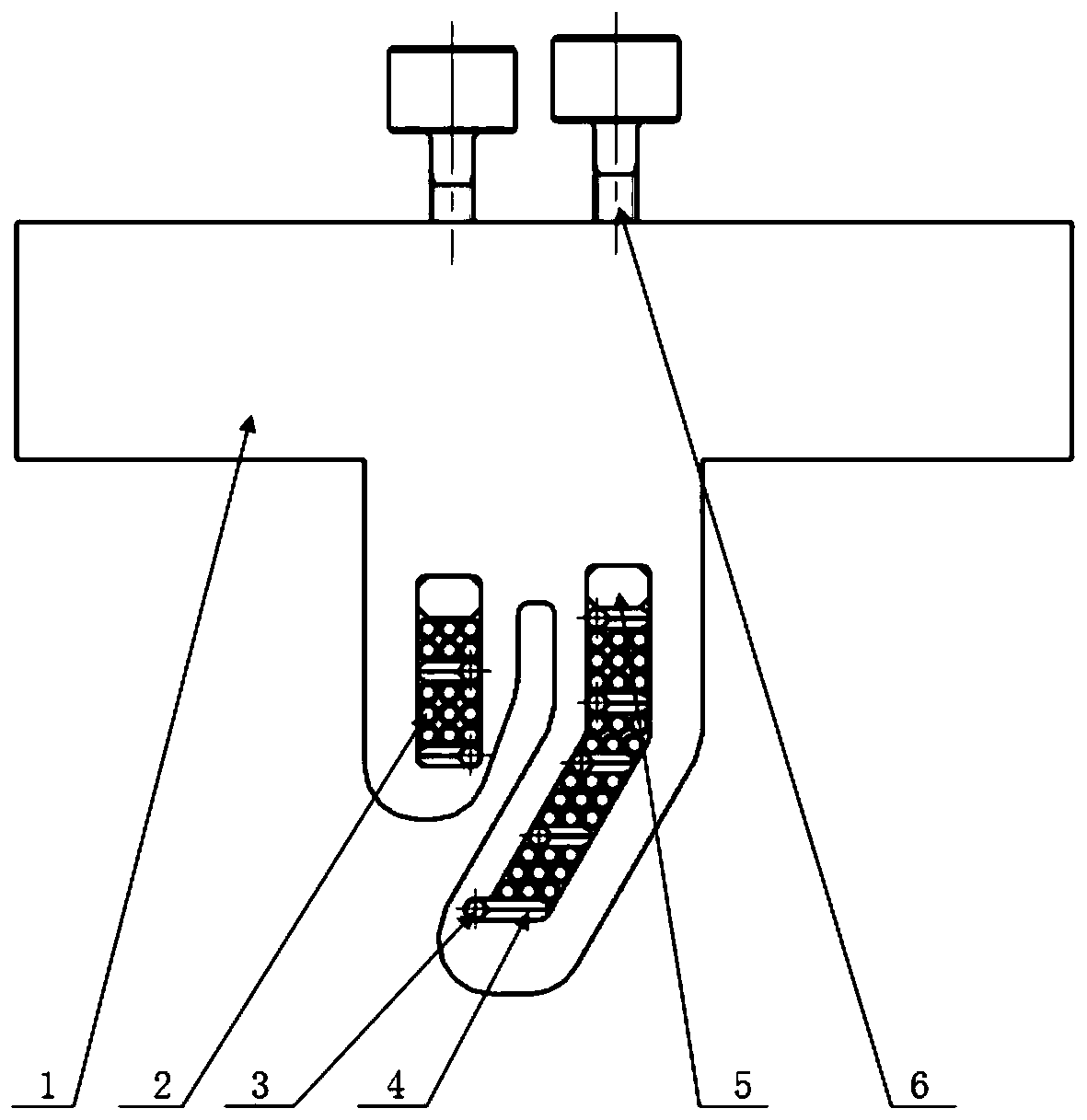

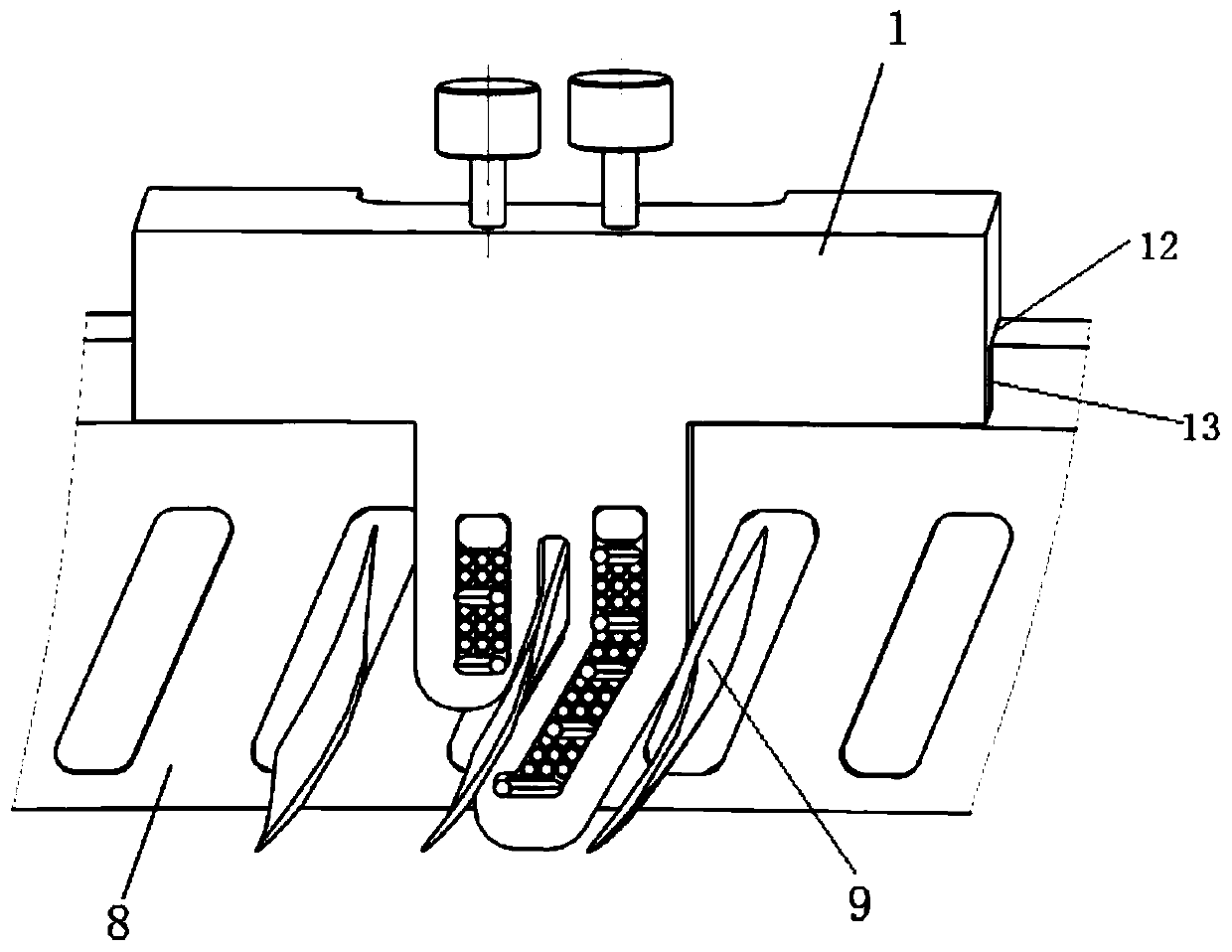

[0049] Such as image 3 As shown, the second part 9 needs to be installed in the hole on the first part 8, and it is required to detect the displacement of the mounting surface of the second part 9 on the part one 8 relative to the arc surface of the first part 8. According to the characteristics of part 18, an end face 12 and an arc surface 13 are designed on the body 1 as the positioning surface. Because the displacement of the parts in the same axial section is the same, there is no need to limit the position along the arc surface when the detection device is used. turn.

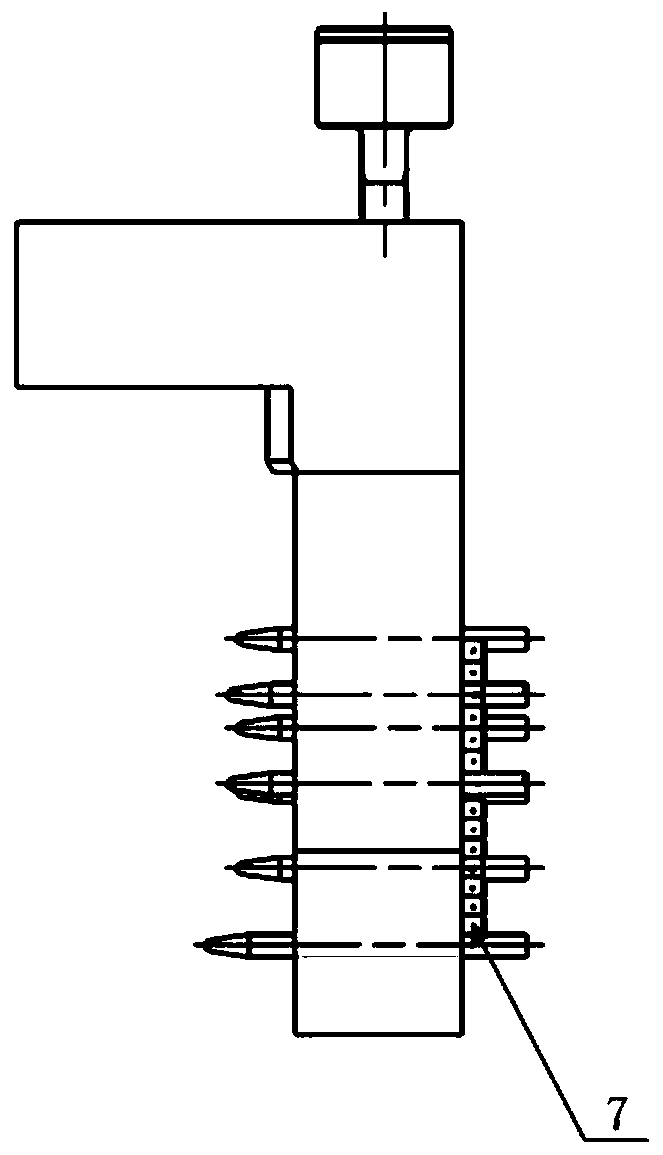

[0050]For the installation structure of part 1 and part 2, the lower half has a first measuring end and a second measuring end, and there is a gap between the first measuring end and the second measuring end. Due to the narrow measurement space, an irregularly shaped body 1 is designed according to the measurement space, and through holes are opened on the first measuring end and the second measuring end...

Embodiment 2

[0053] refer to image 3 To illustrate, there is no part 2 9, and what is required to be detected is the concave and convex amount of the arc surface of part 1 8 itself. At this time, the measured profile and the misaligned profile are the profile of a component. The measuring terminal can be designed as one or more.

[0054] When measuring, the body 1 and the part 18 are positioned well, and the lead-out pin 3 and the L-shaped measuring pin 4 are pressed down by hand, and the lead-out pin 3 and the L-shaped measuring pin 4 are in contact with the profile of the part 18, and the clamping screw 6 is tightened , then take out the detection device, observe the rear end surface of the lead-out needle 3 and the L-shaped measuring needle 4, or judge with the help of a tool, if the end surface of the lead-out needle 3 is between the step surface 11 of the L-shaped measuring needle 4 or is aligned with any end surface of the step surface 11 If it is flat, the amount of misalignment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com