Trapezoidal shielding device for producing corrosion foil for lead-free electrolytic capacitor

A technology of shielding device and capacitor, applied in the field of electrolysis, can solve the problems of shaking up and down and left and right, inaccurate detection, not detecting aluminum foil first, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

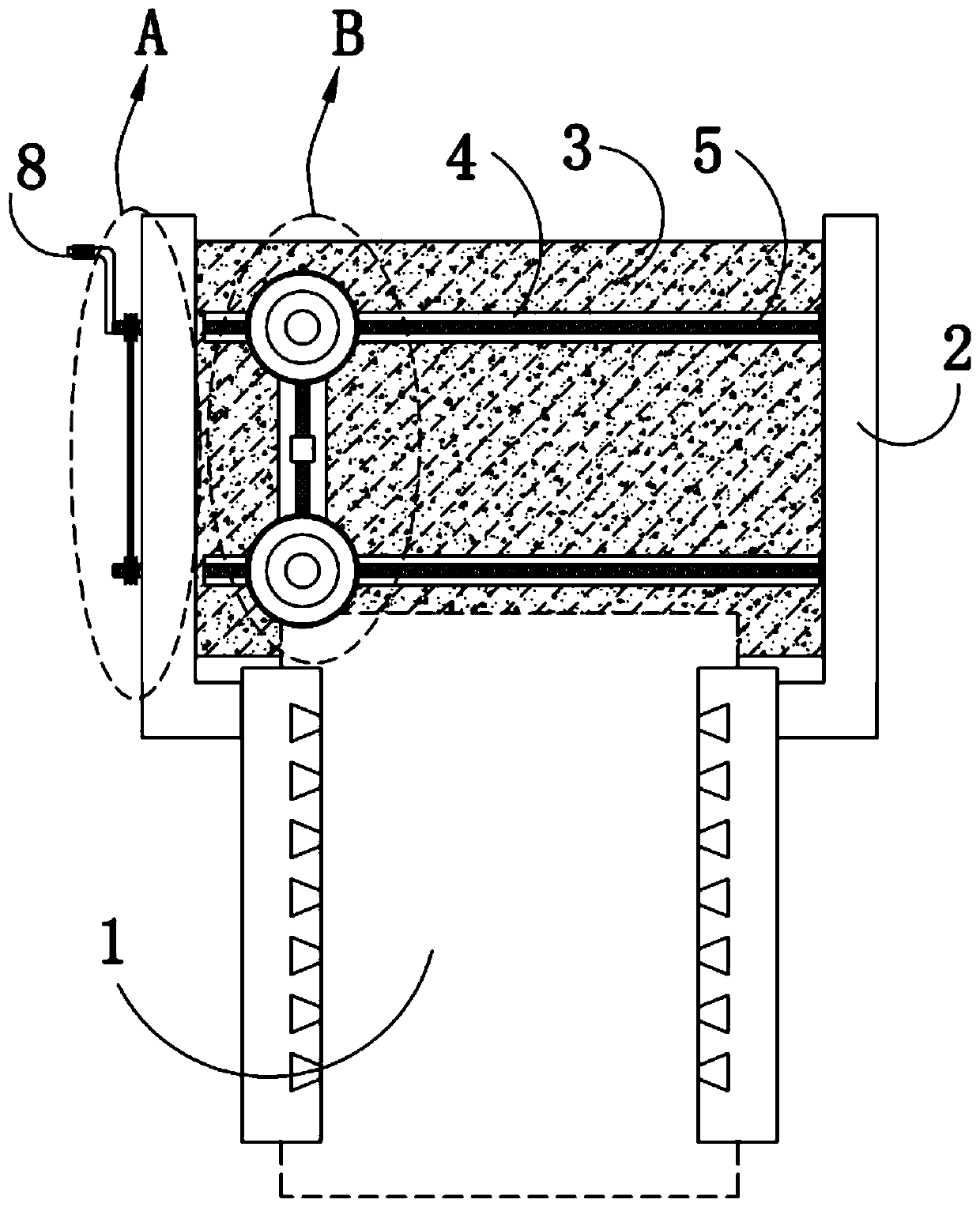

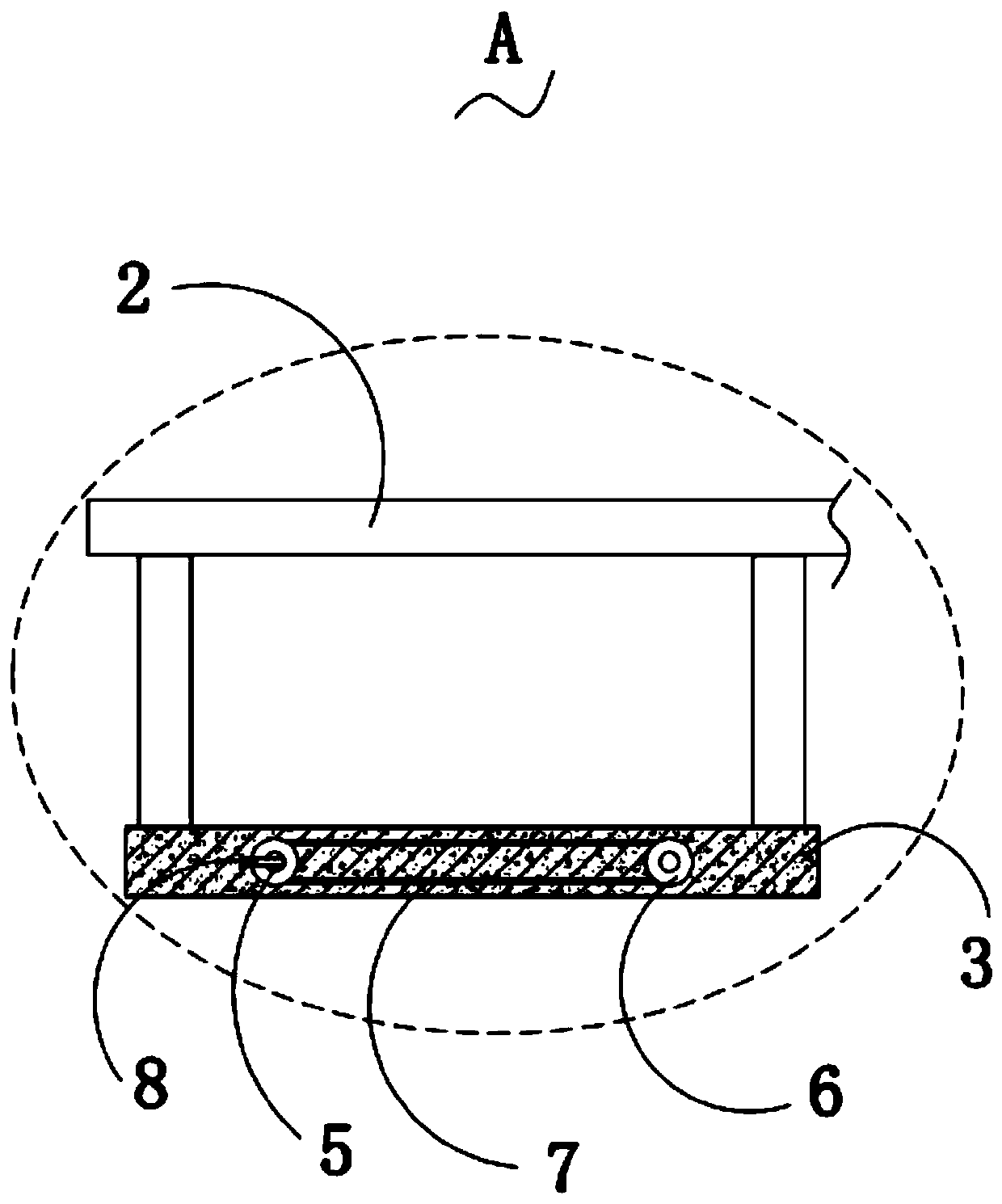

[0026] Please refer to figure 1 and figure 2 ,in, figure 1 A schematic diagram of the top view structure of a preferred embodiment of the trapezoidal shielding device produced by the corrosion foil for the lead-free electrolytic capacitor provided by the invention; figure 2 for figure 1 Schematic diagram of the side-view structure of part A shown. The trapezoidal shielding device produced by corrosion foil for lead-free electrolytic capacitors includes: a trapezoidal shielding device body 1; two L-shaped round rods 2, and the two L-shaped round rods 2 are fixedly installed on the trapezoidal shielding device body 1; A horizontal plate 3, the horizontal plate 3 is arranged below the two L-shaped round rods 2; two first grooves 4, the two first grooves 4 are set on the top of the horizontal plate 3 Two first crossbars 5, two first crossbars 5 are respectively rotatably installed in the two first grooves 4, and one end of the first crossbar 5 extends to the corresponding fi...

Embodiment 2

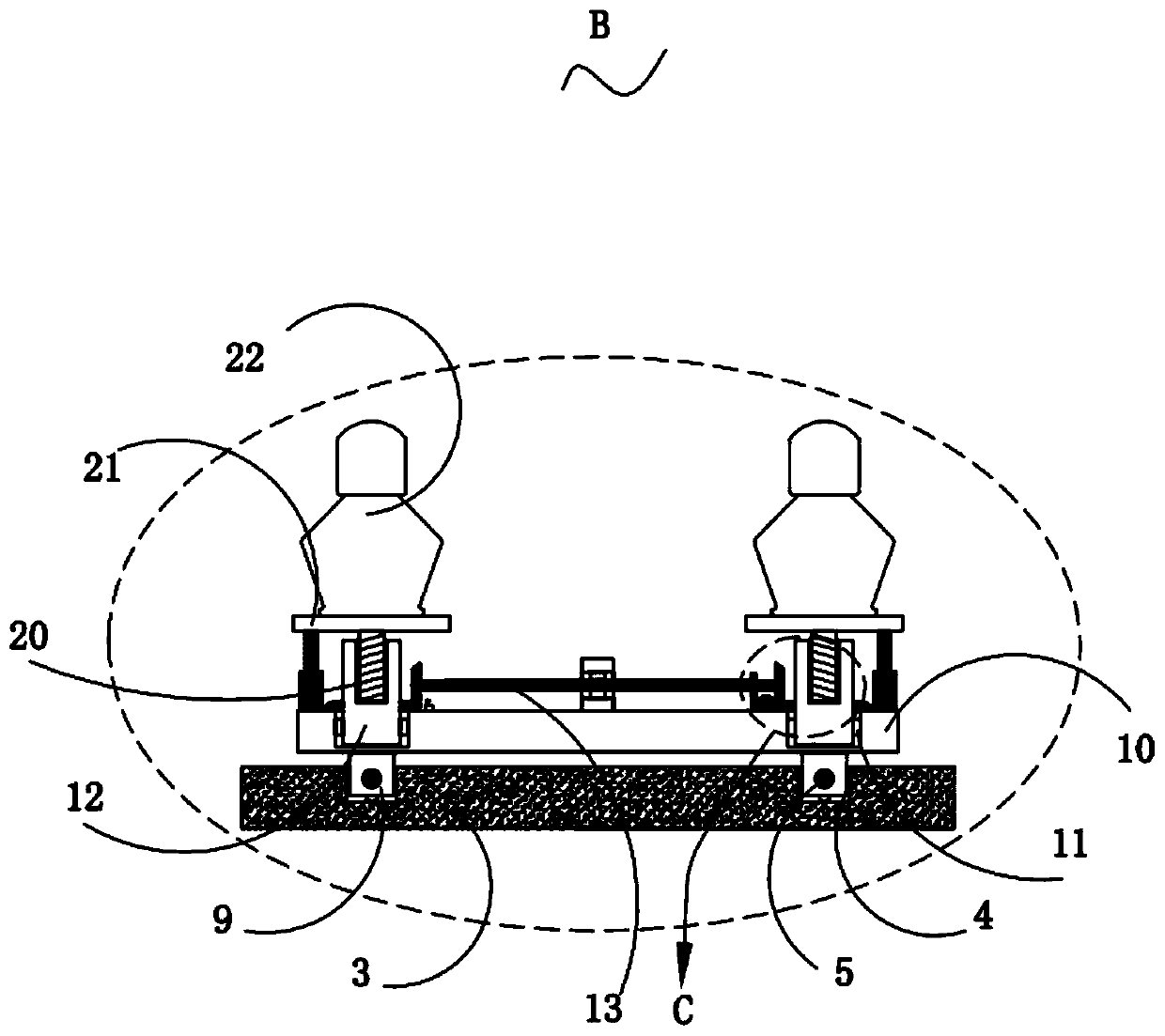

[0032] Please combine image 3 , Figure 4 and Figure 5 ,in, image 3 for figure 1 The schematic diagram of the side view sectional structure of part B shown; Figure 4 for image 3 The schematic diagram of the enlarged structure of part C shown; Figure 5 is an assembly diagram of the first bevel gear and the second bevel in the present invention.

[0033] Described elevating mechanism comprises slide block 9, bar block 10, the second groove 11, the first round bar 12, the second cross bar 13, the first bevel gear 14, the second bevel gear 15, motor 16, the first A circular gear 17, a second circular gear 18, a third groove 19, a second round bar 20 and a circular plate 21, the threaded sleeve on the first cross bar 5 is provided with a slide block 9, and the slide block 9 extends to the outside of the corresponding first groove 4, the tops of the two sliders 9 are fixedly installed with the same bar block 10, and the top of the bar block 10 is symmetrically provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com