Physical simulation and numerical simulation combined measurement method for crack generation full-diameter rock core

A full-diameter core and physical simulation technology, which is applied in the measurement field of fracture-making full-diameter core physical simulation and numerical simulation, can solve the problem of long period of high-temperature and high-pressure physical experiment of full-diameter core, system error, high cost of physical experiment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

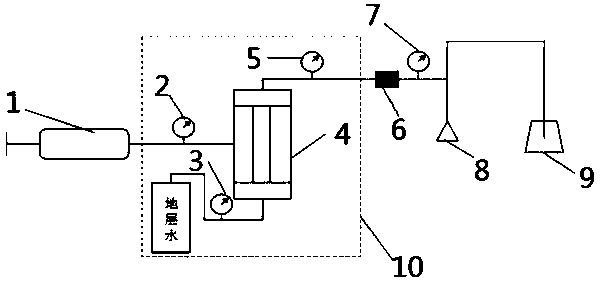

[0063] 1. In order to ensure the quantitative comparability of the simulation experiment, the experimental design analysis first extracts the main influencing factors of gas reservoir water intrusion, and then sets the parameter level values of the factors according to the actual situation on site, and then carries out the corresponding physical simulation experiments and some numerical simulations experiment.

[0064] The influencing factors of this extraction include four factors: fracture permeability, fracture dip angle, fracture penetration degree, and water body size.

[0065] Considering the experimental comparability, the number of cores and the cost of the experiment, the factor level value used in this analysis is 3 levels, so the L with 4 factors and 3 levels can be used. 9 (3 4 ) Orthogonal experiment table to carry out the design of experimental projects. The experiment of water invasion mechanism in complex carbonate gas reservoirs is based on the gas and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com