Detection method for micro faults in chemical process

A chemical process and fault detection technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve the problem of low detection rate of small faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

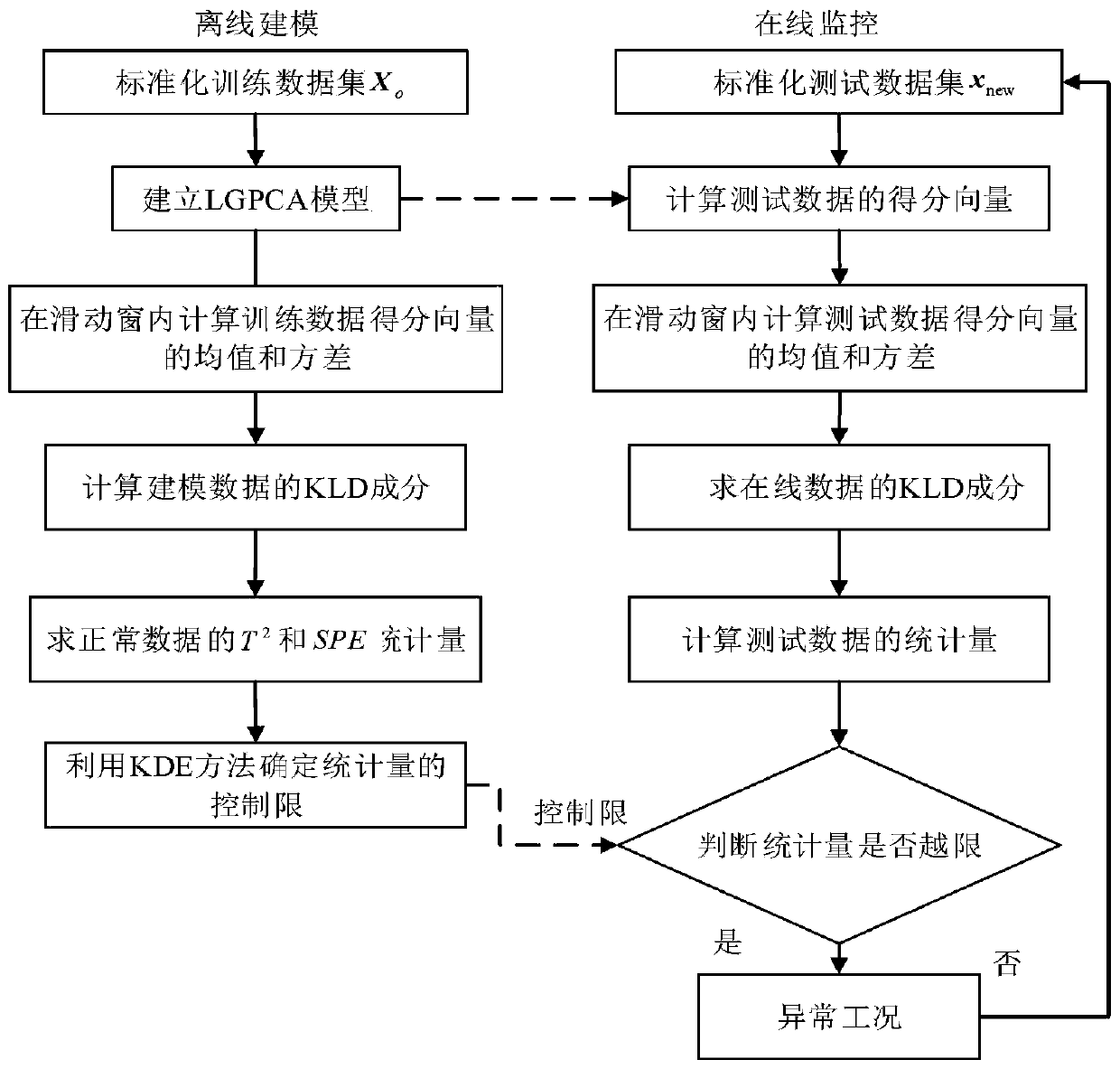

Method used

Image

Examples

Embodiment

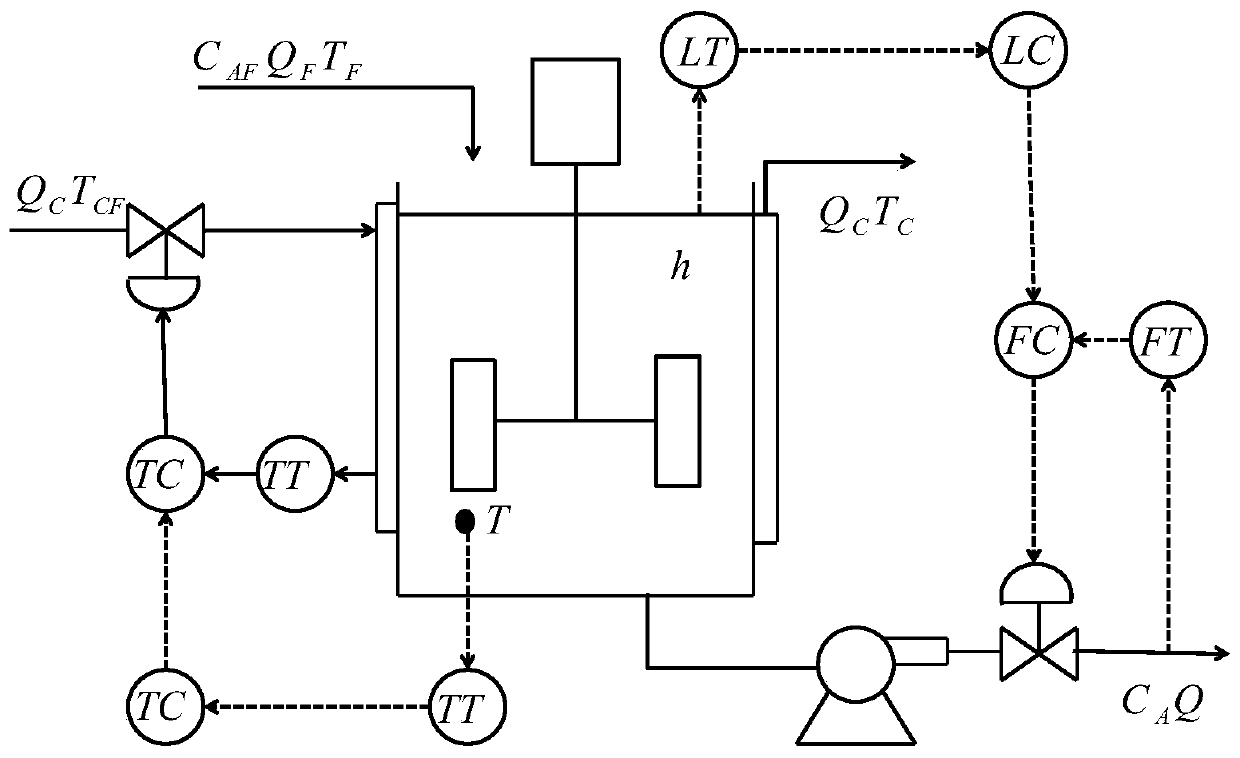

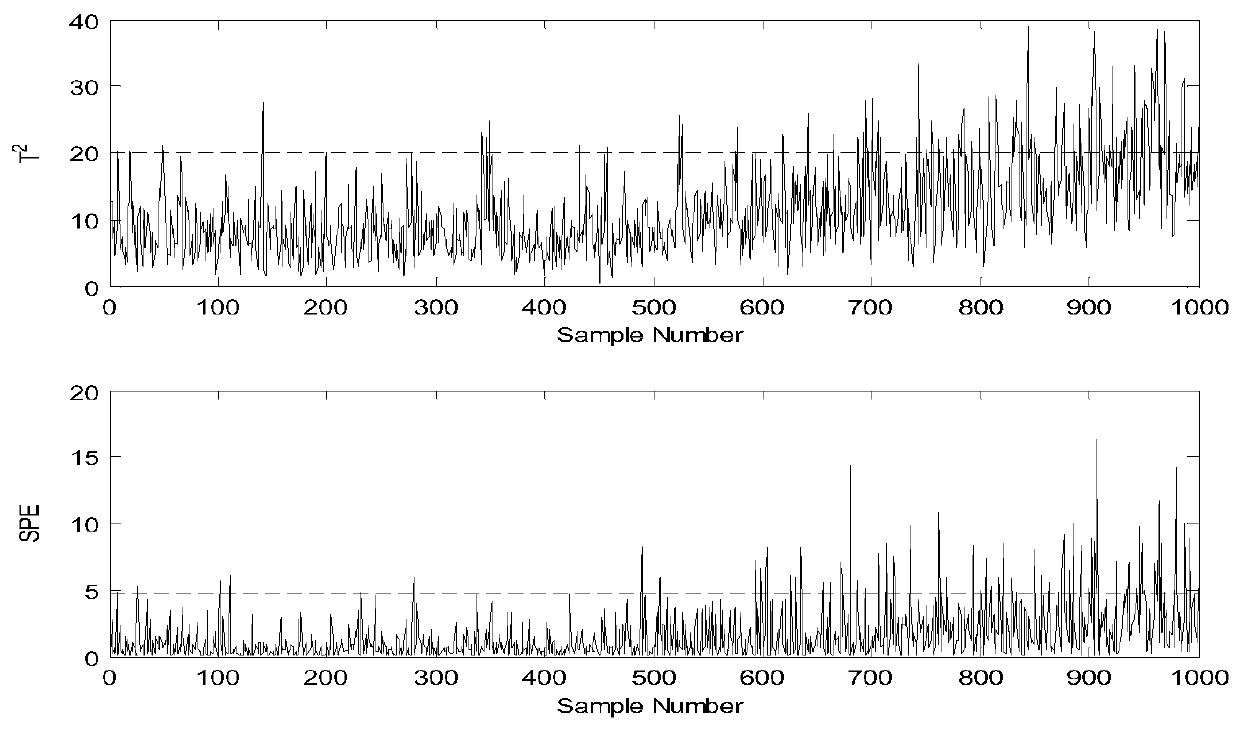

[0125] The continuous stirred reactor (hereinafter referred to as: CSTR) system is a typical nonlinear chemical process control system, which is widely used in the field of fault detection and diagnosis. see figure 2 , The CSTR system includes a temperature and liquid level control loop, and substance A undergoes a first-order irreversible exothermic reaction in the reactor to form substance B. During the simulation, measurement noise is added to simulate normal and six fault conditions. The process data information is collected from 10 variables of the CSTR system, including 4 state variables and 6 input variables, see Table 1 for details. The 6 faults used in this embodiment are shown in Table 2, and the monitoring performance of each method is verified through the faults in Table 2. Both normal and fault conditions contain 1000 samples. First, 1000 sets of normal data are simulated as a training set for historical modeling. In order to generate fault data, a fault is int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com