Preparation method of metal side wall and device structure

A technology for metal sidewalls and device structures, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of inability to prepare ultra-thin metal sidewalls, limited lithography accuracy, etc. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

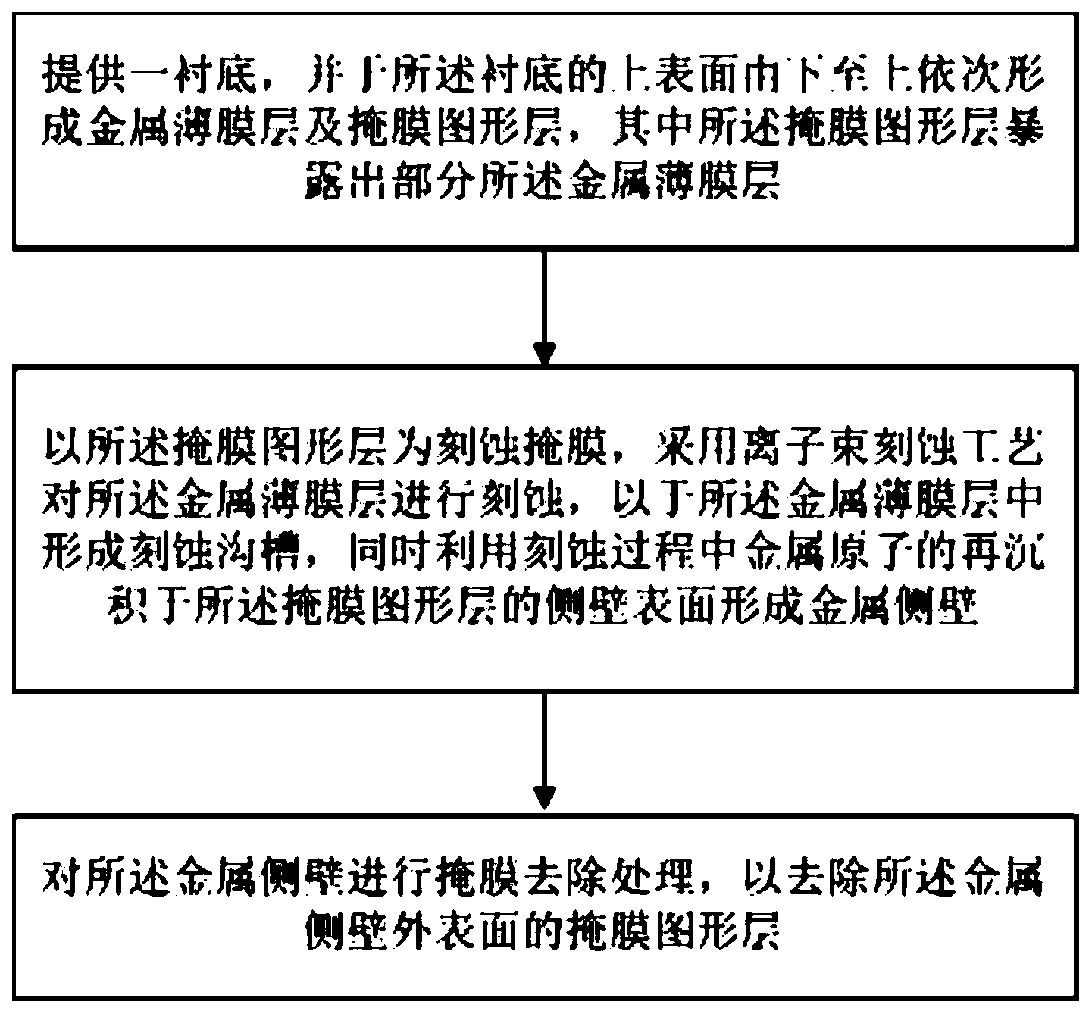

[0035] Such as figure 1 As shown, this embodiment provides a method for preparing a metal sidewall, the preparation method comprising:

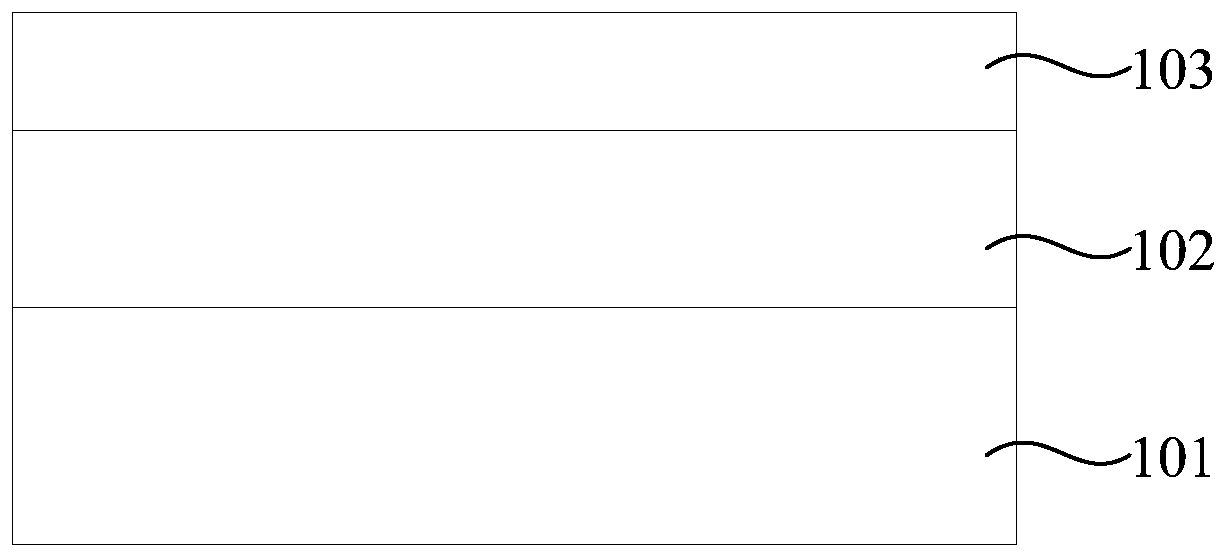

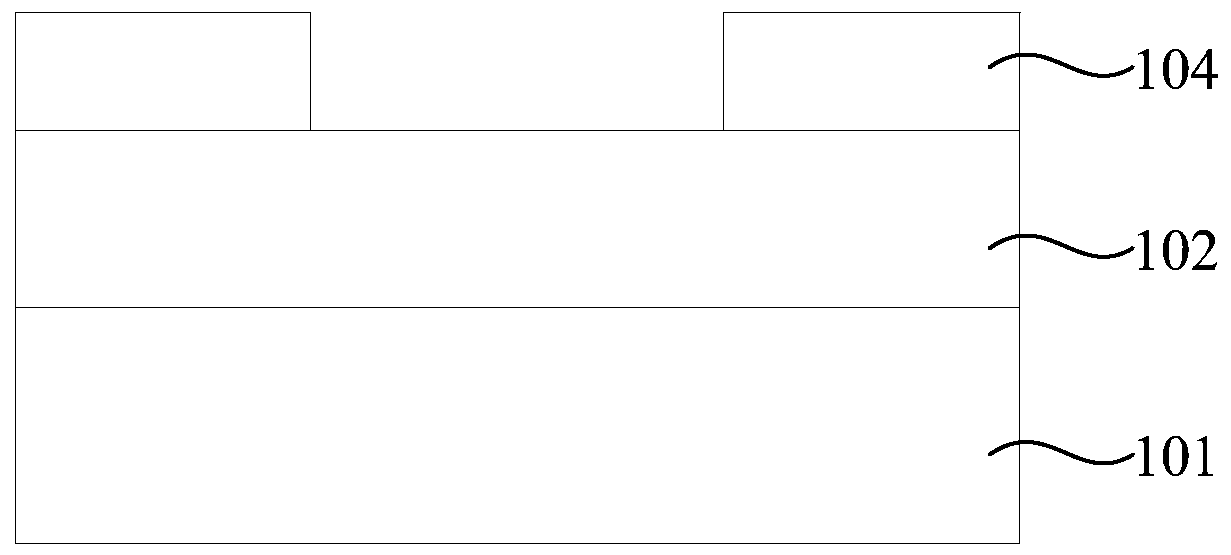

[0036] Provide a substrate 101, and sequentially form a metal thin film layer 102 and a mask pattern layer 104 on the upper surface of the substrate 101 from bottom to top, wherein the mask pattern layer 104 exposes part of the metal thin film layer 102;

[0037] Using the mask pattern layer 104 as an etching mask, the metal thin film layer 102 is etched by an ion beam etching process, so as to form an etching groove 105 in the metal thin film layer 102. Re-deposition of metal atoms in the etching process forms metal sidewalls 106 on the sidewall surface of the mask pattern layer 104;

[0038] Mask removal treatment is performed on the metal sidewall 106 to remove the mask pattern layer 104 on the outer surface of the metal sidewall 106 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com