Installation method of electrical equipment

An installation method and technology for electrical equipment, which are applied in the processing of electrical equipment casings/cabinets/drawers, electrical components, and building materials, etc., can solve the problems of space-consuming replacement and maintenance of electrical equipment, difficulties, etc., and achieve easy dismantling and maintenance. and replacement, the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for installing electrical equipment, which includes the following steps:

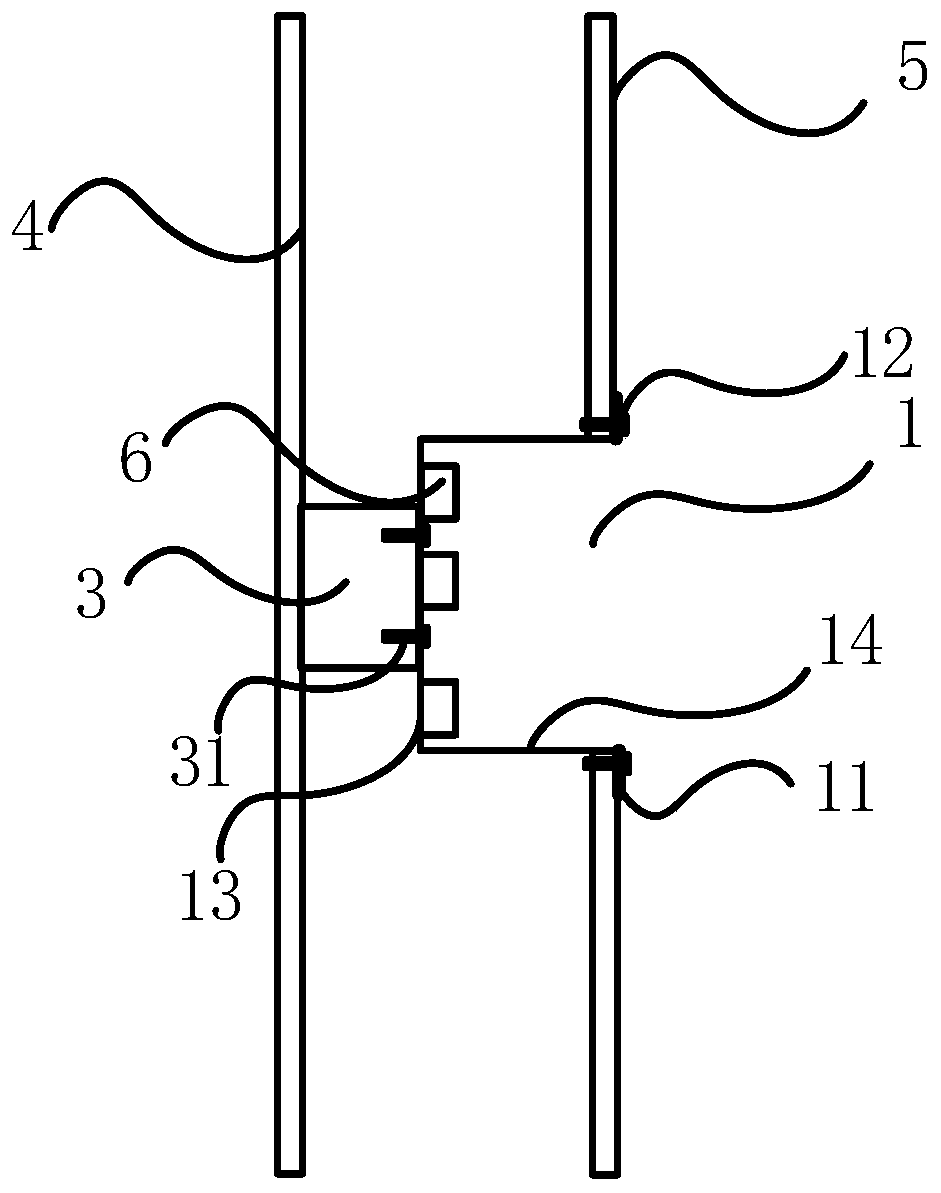

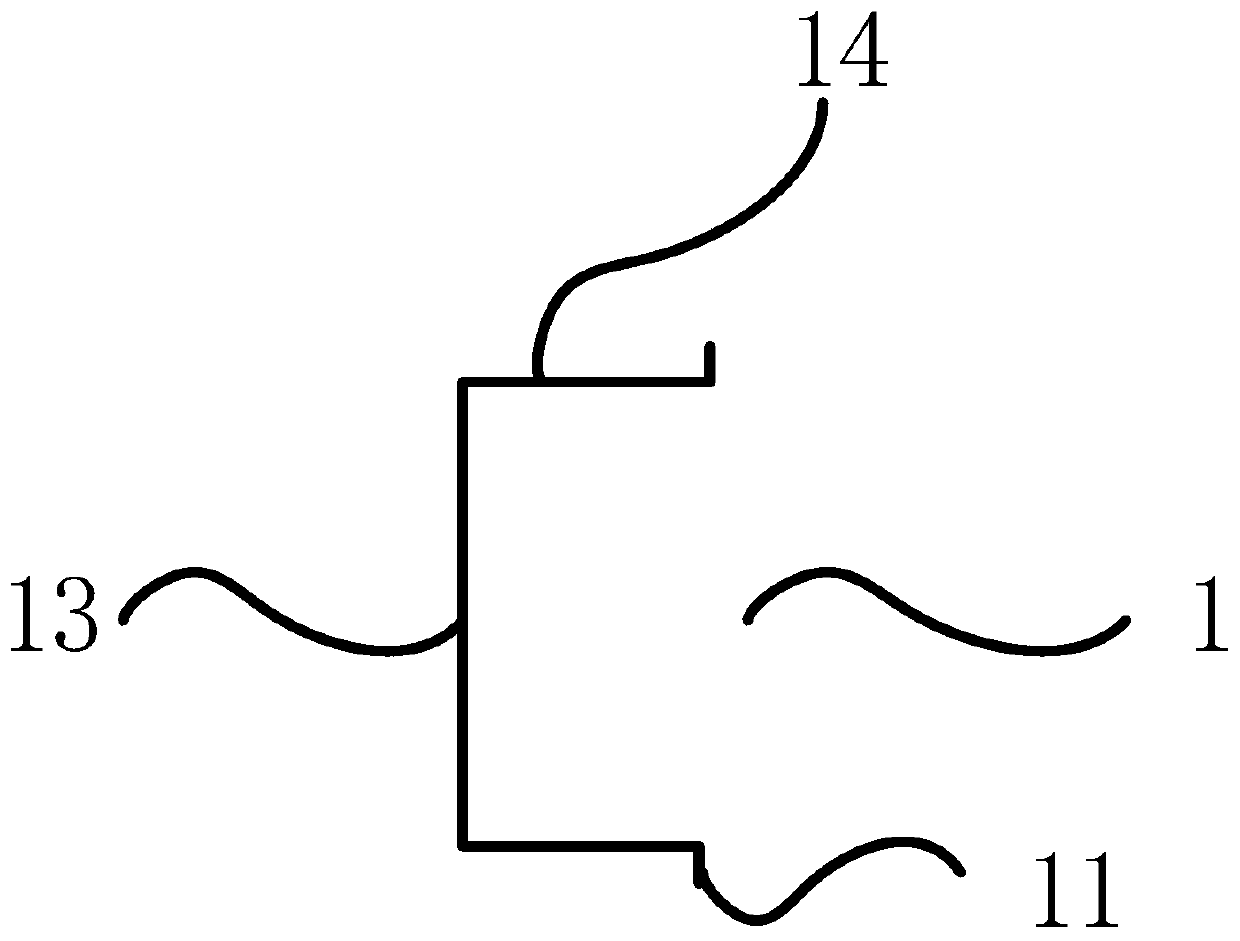

[0024] Step S1 welds the base 3 for reinforcing the window-type base 1 on the inner side of the steel wall 4, the window-type base 1 includes a bottom plate 13, a side plate 14 and a peripheral side plate 11, and the shape of one end of the side plate 14 is the same as that of the bottom plate 13 It is a rectangular structure that overlaps with each other, and is welded to each other to form a cuboid structure without a top plate, wherein the height of the side plate 14 is less than the distance between the steel wall 4 and the wooden wall 5; the peripheral side plate 11 is used for the window type base 1 and the wood wall The connection between the surrounding walls 5 is welded to the other end of the side plate 14; the base 3 and the bottom plate 13 of the window-type base 1 are placed opposite and matched;

[0025] Step (1) install the wooden wall 5, on the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com