Semi-automatic selenium sand melon transplanter

A technology of selenium sand melon and transplanting machine, which is applied in transplanting machinery, planting methods, soil preparation machinery and other directions, can solve the problems of low degree of automation, high labor cost, difficult operation, etc., and achieves high degree of automation and soil gathering operation. The effect of standardizing and reducing transplanting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described:

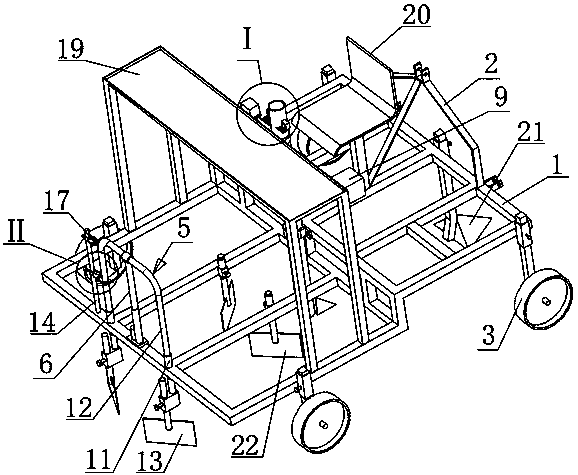

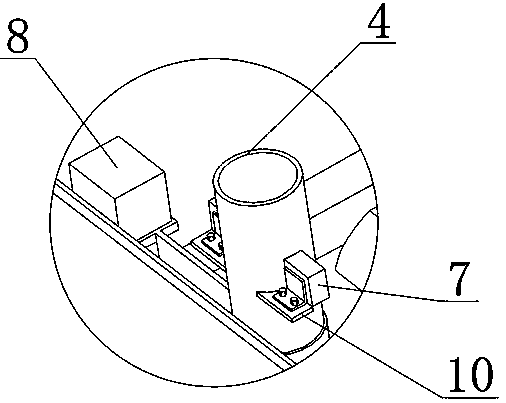

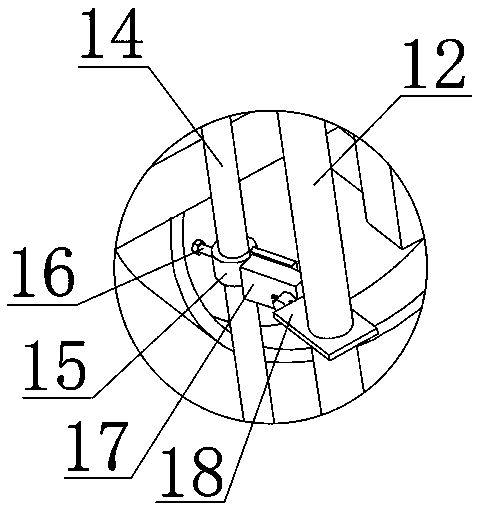

[0031] Such as Figures 1 to 7 Shown, a kind of semi-automatic selenium sand melon transplanting machine; It comprises frame 1, throwing seedling device, ditching device, covering soil device and collecting soil seedling protecting device; Frame 1 is used for being connected with agricultural tractor and realizes walking; Throwing The seedling device is used to put melon seedlings manually, and the melon seedlings fall under the action of gravity; the ditching device is used to form a planting ditch; the soil covering device is used to cover the transplanted melon seedlings; the soil gathering device is used to form a ring of soil around the melon seedlings heap.

[0032] Frame 1, which can be welded by steel pipes to form a lattice structure; its front end is provided with a traction frame 2, and the traction frame 2 adopts a three-point suspension type tracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com