Environment-friendly and energy-saving cooling, precipitating and filtering integrated system for wire drawing liquid and using method of same

A comprehensive system, environmental protection and energy-saving technology, applied in separation methods, precipitation separation, chemical instruments and methods, etc., can solve the problems of high price of drawing liquid, shortening the service life of drawing liquid, and accelerating the deterioration of drawing liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

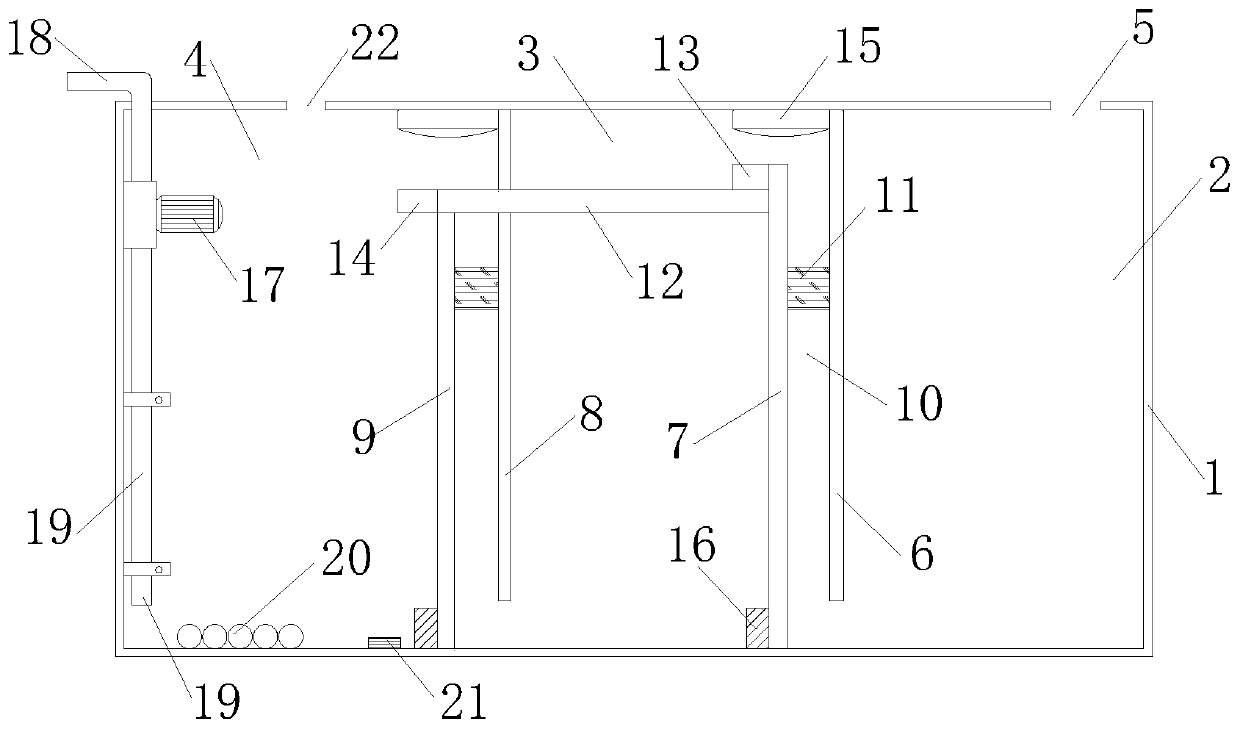

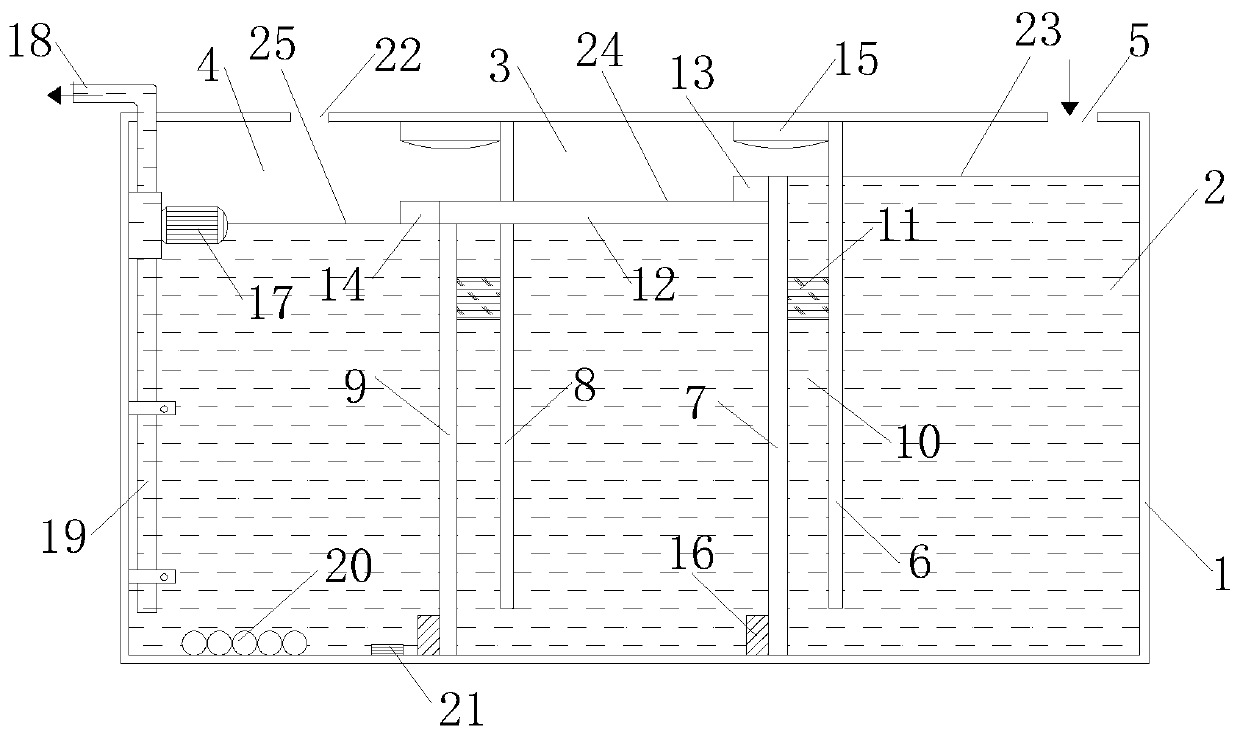

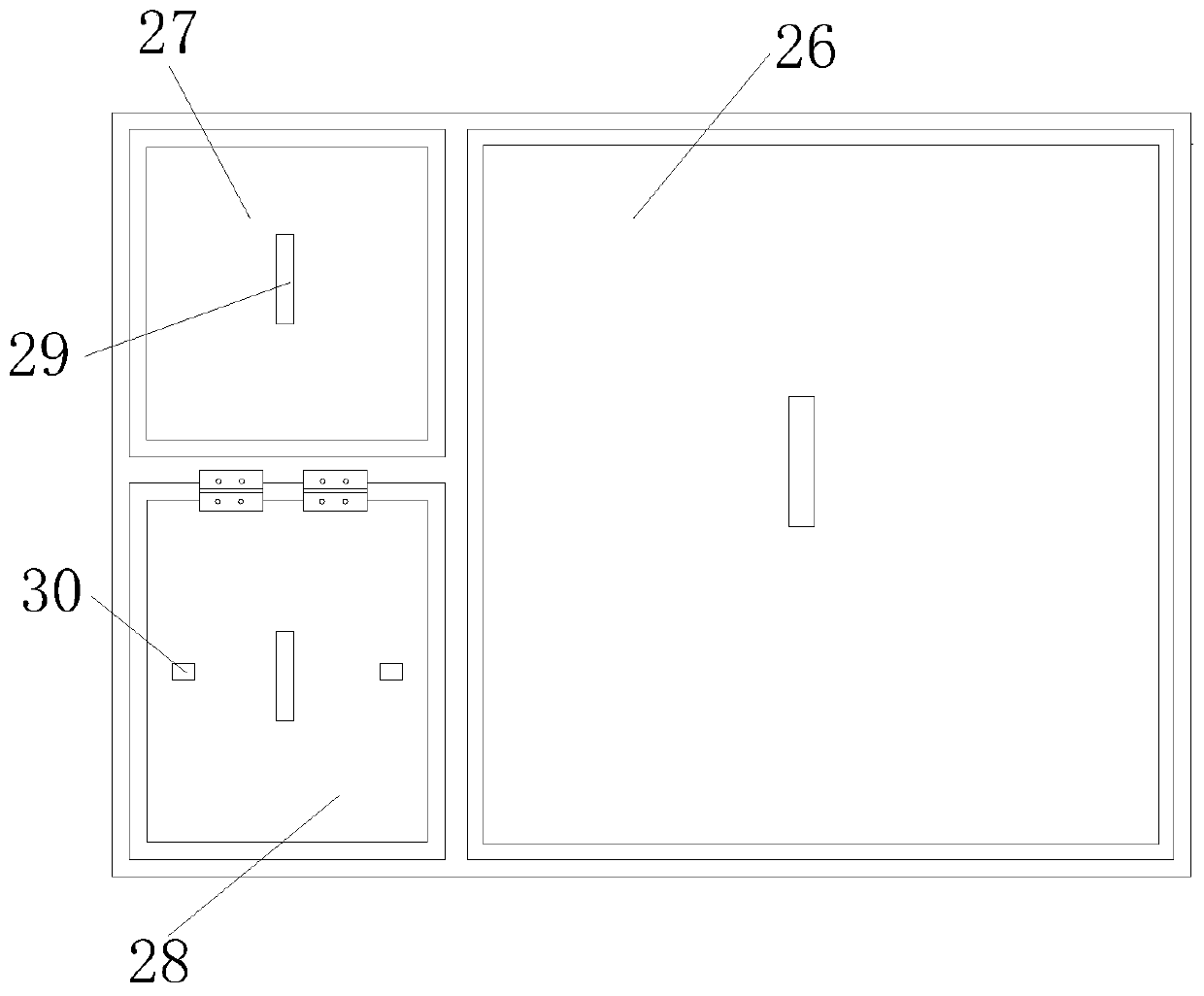

[0029] Example. Drawing liquid environmental protection and energy saving cooling sedimentation filtration comprehensive system, such as Figure 1 to Figure 3As shown, the integrated system body 1 is included, the integrated system body 1 is provided with a liquid inlet tank 2, and the upper end of the liquid inlet tank 2 is provided with a liquid inlet 5, and the liquid inlet tank 2 passes through the first partition 6 and the second partition 7 The channel 10 between is communicated with the middle tank 3, and the middle tank 3 is communicated with the liquid outlet tank 4 through the channel 10 between the third partition 8 and the fourth partition 9, and a filter part 11 is arranged in the channel 10, and the first partition The top of 6 and the top of the third partition 8 are fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com