Flat cable production line

A production line and cable technology, used in cable/conductor manufacturing, insulation of conductors/cables, circuits, etc., can solve the problems of restricting the development of cable production, large emissions, and high cost, and achieves omission of equipment, high thermal efficiency, and fast production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

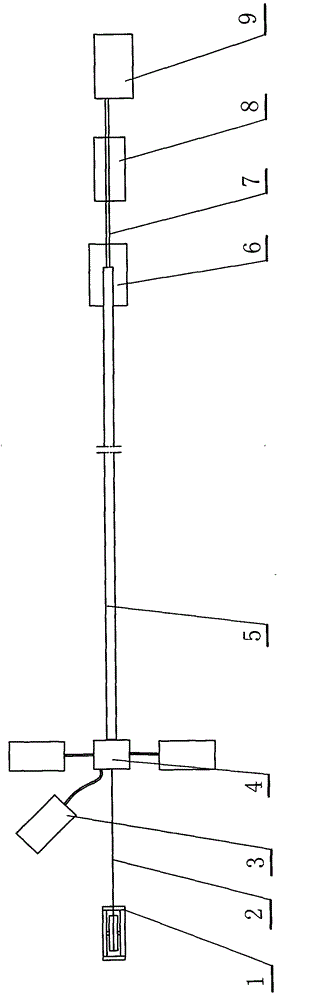

[0024] The general idea of the present invention is to change the existing vertical cable production line into a horizontal cable production line, especially the high-voltage cable above 35kv, and the ultra-high voltage cable production line above 110kv into a horizontal production line, so as to reduce investment. , The purpose of reducing costs. Around this idea, the following four examples are given:

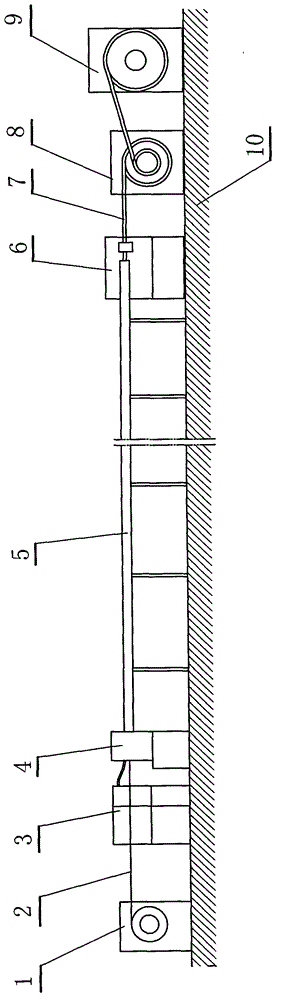

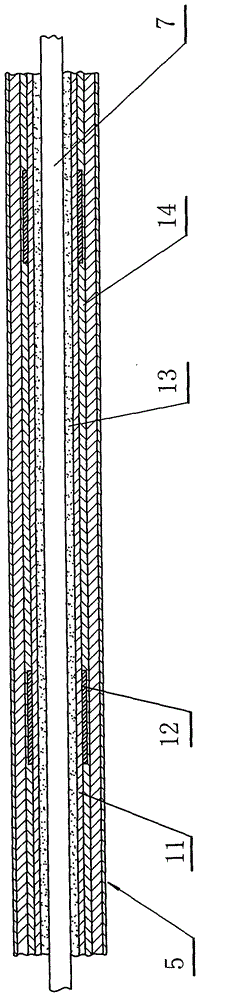

[0025] The first embodiment: as figure 1 , 2 As shown, the front end of this cable production line has a wire frame 1 for supporting and conveying the wire 2, an extruder 3 for hot-melting and extruding the wrapping layer material, a head 4 for completing the wrapping layer and wire wrapping, and a Vulcanized or cross-linked cross-linked pipeline 5, the rear end of the cross-linked pipeline 5 is provided with a sealing device for cables to pass through and to prevent the medium from overflowing, and there are wire drawing machines 8 and winding machines 9 at the rear end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com