Oil filtering system and method

A filtration system and oil technology, applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of poor filtration effect and singleness, and achieve the effect of speeding up discharge, ensuring filtration efficiency and improving filtration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

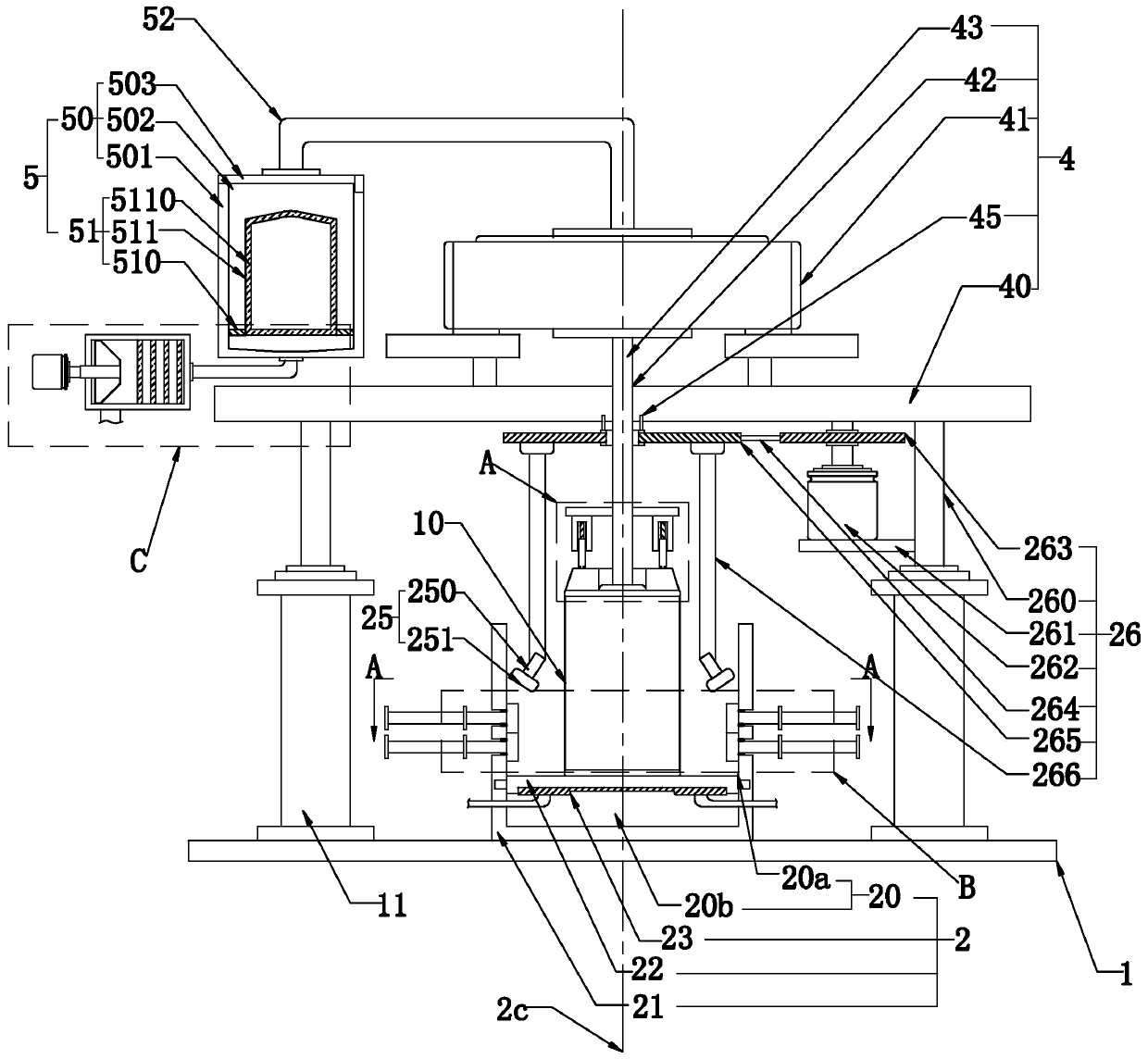

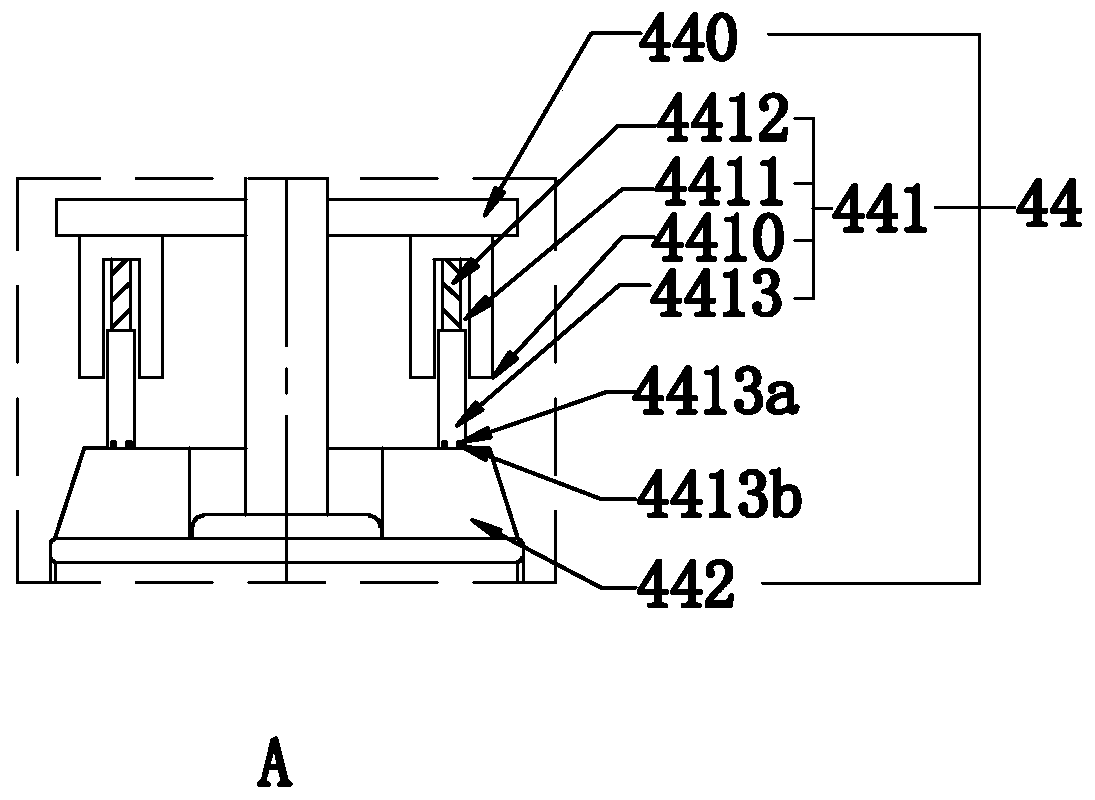

[0030] Such as Figure 1 to Figure 6 As shown, the present invention discloses a grease filtering system, including a frame 1, in a specific embodiment of the present invention, including a preheating assembly 2 installed on the frame 1 and used to place a lubricating oil storage tank 10, partly located The extruding assembly 3 inside the preheating assembly 2 is used to squeeze the outer wall of the lubricating oil storage tank 10 from bottom to top, and the feeding assembly 4 is driven up and down by the cylinder 11 and is located directly above the preheating assembly 2 and is used to extract lubricating oil. And a filter assembly 5 communicating with the feeding assembly 4 and used for receiving lubricating oil and filtering it.

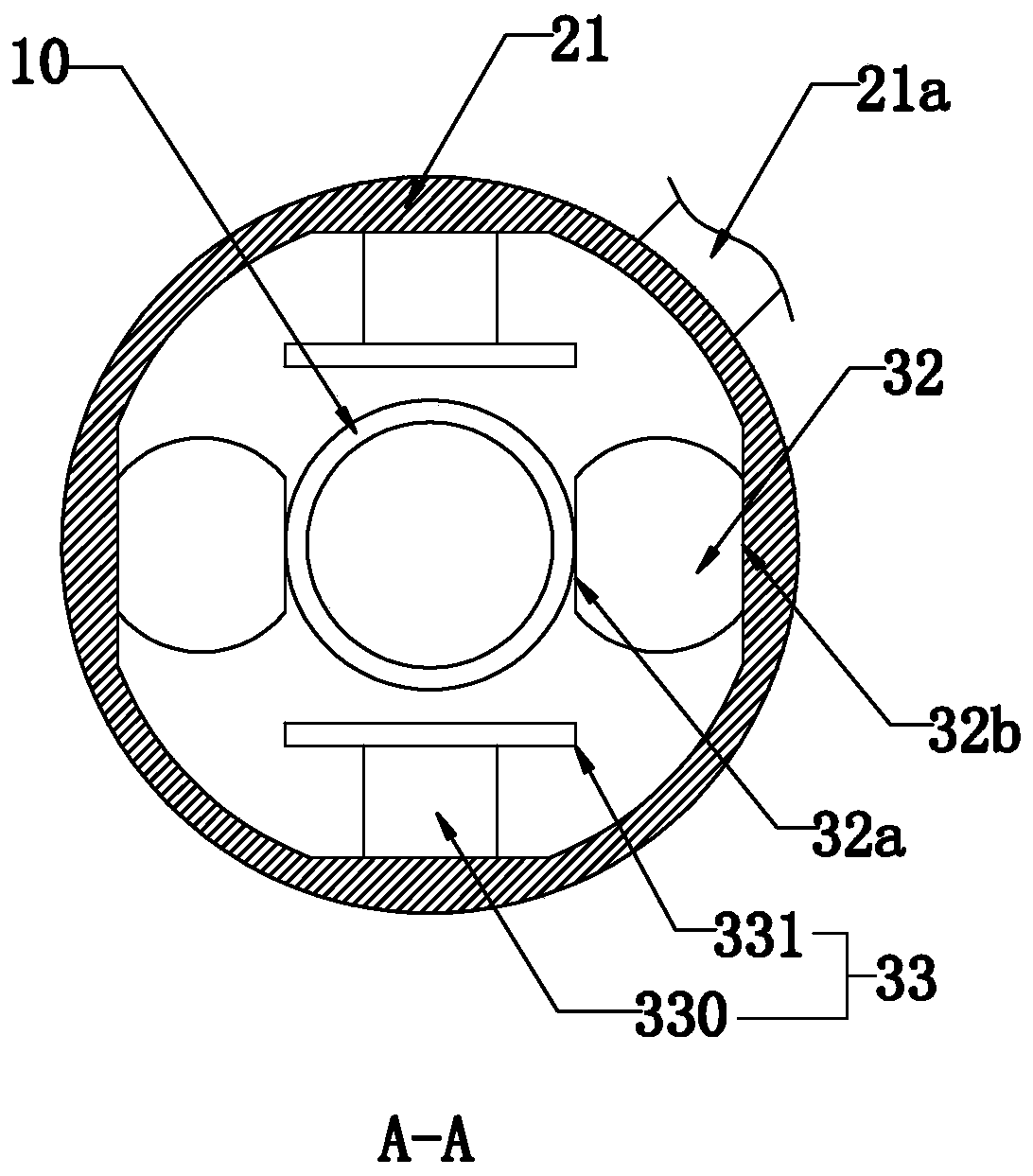

[0031]In a specific embodiment of the present invention, the preheating assembly 2 includes a preheating cylinder 21 fixedly connected to the frame 1 and having a storage chamber 20, fixedly connected to the inner wall of the preheating cylinder ...

Embodiment 2

[0056] A method for filtering grease as claimed in the preceding claims, comprising the steps of:

[0057] S1 storage tank installation: Open the tank cover on the top of the storage tank with lubricating oil in advance and put it into the preheating cylinder, lift the support platform through the cylinder so that one end of the oil inlet pipe penetrates into the storage tank from the top of the storage tank and stops. And through the limit module set on the oil inlet pipe to contact with the top of the storage tank, the installation is completed;;

[0058] S2 Pre-heating treatment: Add an appropriate amount of water into the pre-heating cylinder, and then heat it through the above-mentioned electromagnetic heater, keep the water temperature at 75°C, and start pumping the lubricating oil after 15 minutes of pre-heating time;

[0059] S3 Drain and squeeze: Drain all the water in the preheating cylinder, drive the extrusion module through the hydraulic cylinder to squeeze the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com