Fiberboard drying waste gas treatment system and fiberboard drying waste gas treatment process

A technology of waste gas treatment and fiberboard, which is applied in the field of fiberboard drying waste gas treatment system and fiberboard drying waste gas treatment process, can solve the problems of limiting pollutant purification rate, improvement, and inability to biodecompose and purify organic pollutant components, so as to reduce secondary pollution , reduce waste of resources, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

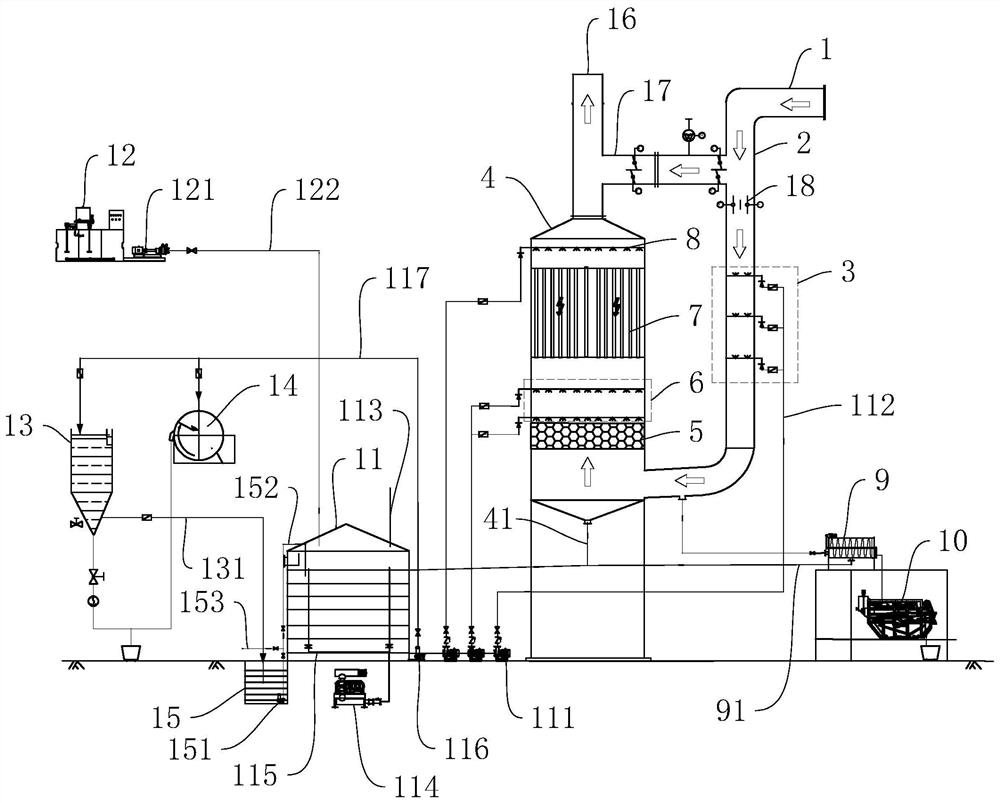

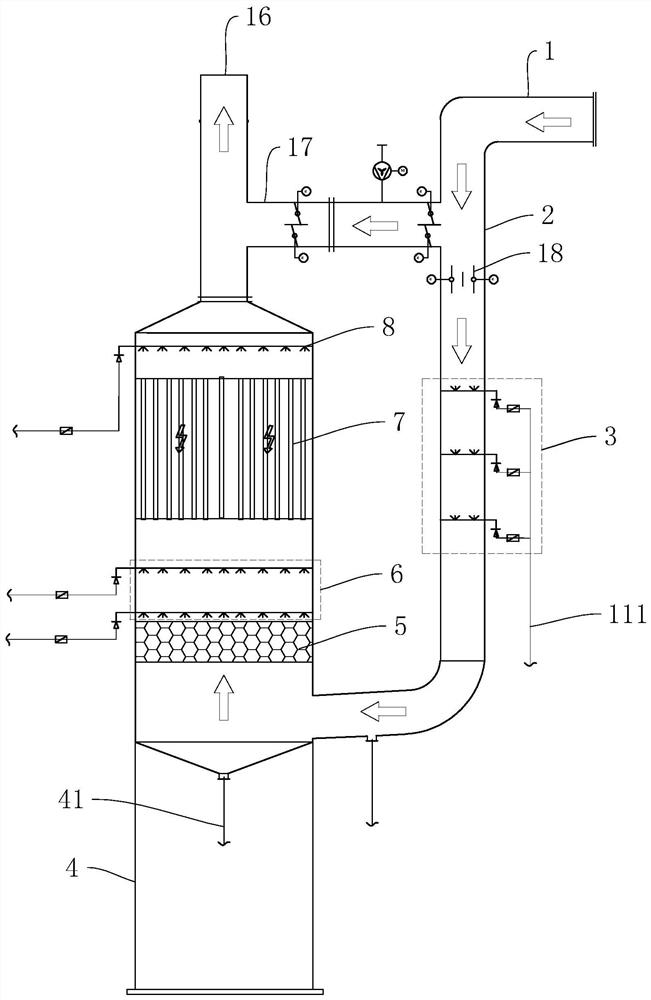

[0040] A fiberboard drying waste gas treatment system, refer to figure 1 , which includes a spray pipe 2 and a spray tower 4 arranged vertically and whose axes are parallel to each other. The top of the spray tower 4 is communicated with a section of air induction pipe 1 , and the air induction pipe 1 is arranged vertically to the spray pipe 2 . The end of the air induction pipe 1 far away from the spray pipe 2 communicates with the air outlet of the cyclone separator (not shown in the figure), so as to guide the fiberboard dry waste gas that has undergone cyclone dust removal into the spray pipe 2 .

[0041] refer to figure 1 with figure 2 A control valve 18 and a first spray device 3 are sequentially arranged in the spray pipe 2 from top to bottom, and the first spray device 3 communicates with the water supply unit. The control valve 18 is used to control the opening and closing of the spray pipe 2, and the first spray device 3 is used to spray liquid mist into the spra...

Embodiment 2

[0057] A fiberboard drying waste gas treatment process is characterized in that the fiberboard drying waste gas treatment system of Embodiment 1 is used to treat the waste gas.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap