Full-automatic rotary disc type mold casting production equipment

A casting production, turntable technology, applied in casting equipment, casting workshop, pig iron casting workshop, etc., can solve the problems of high cost and exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

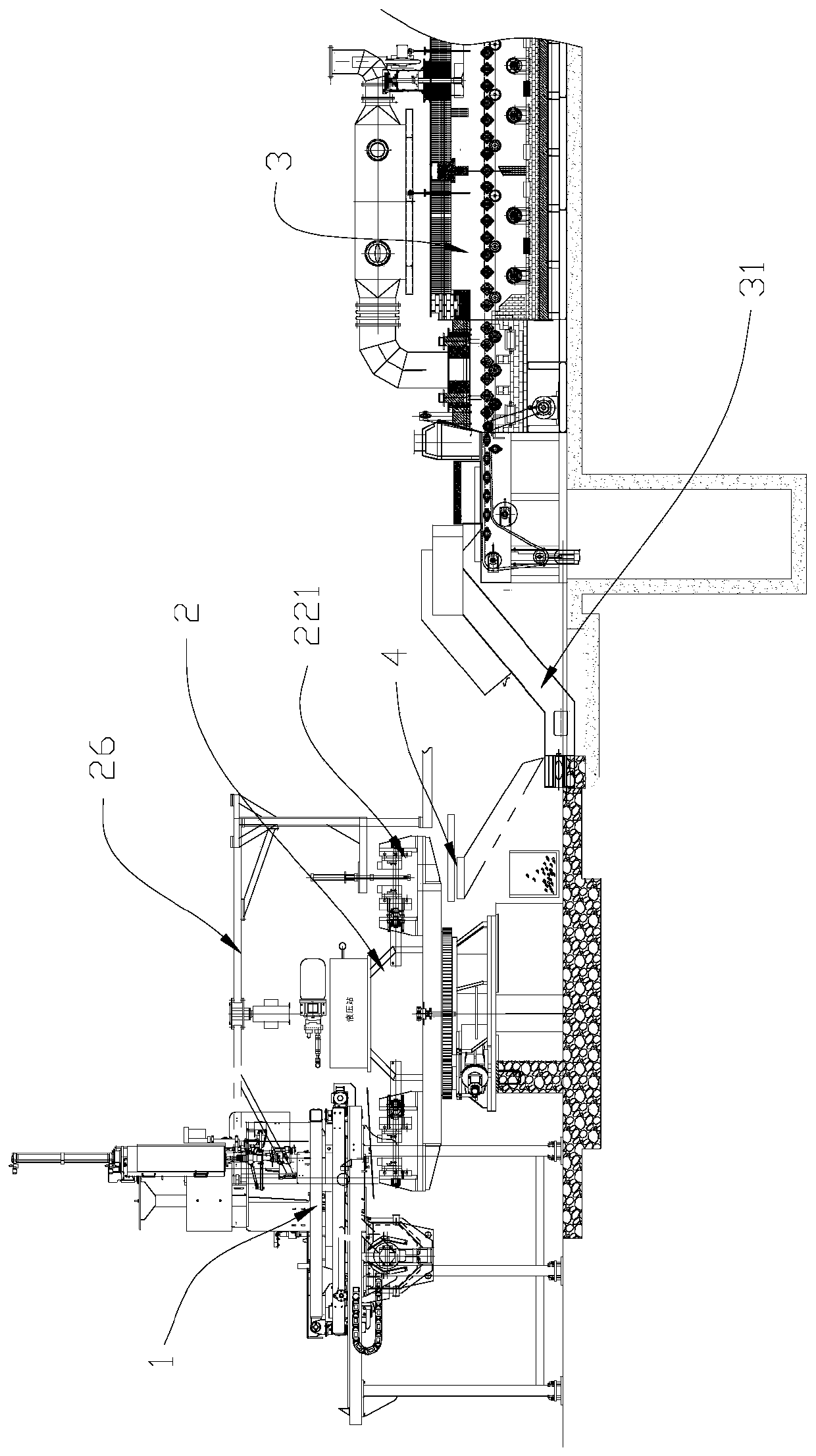

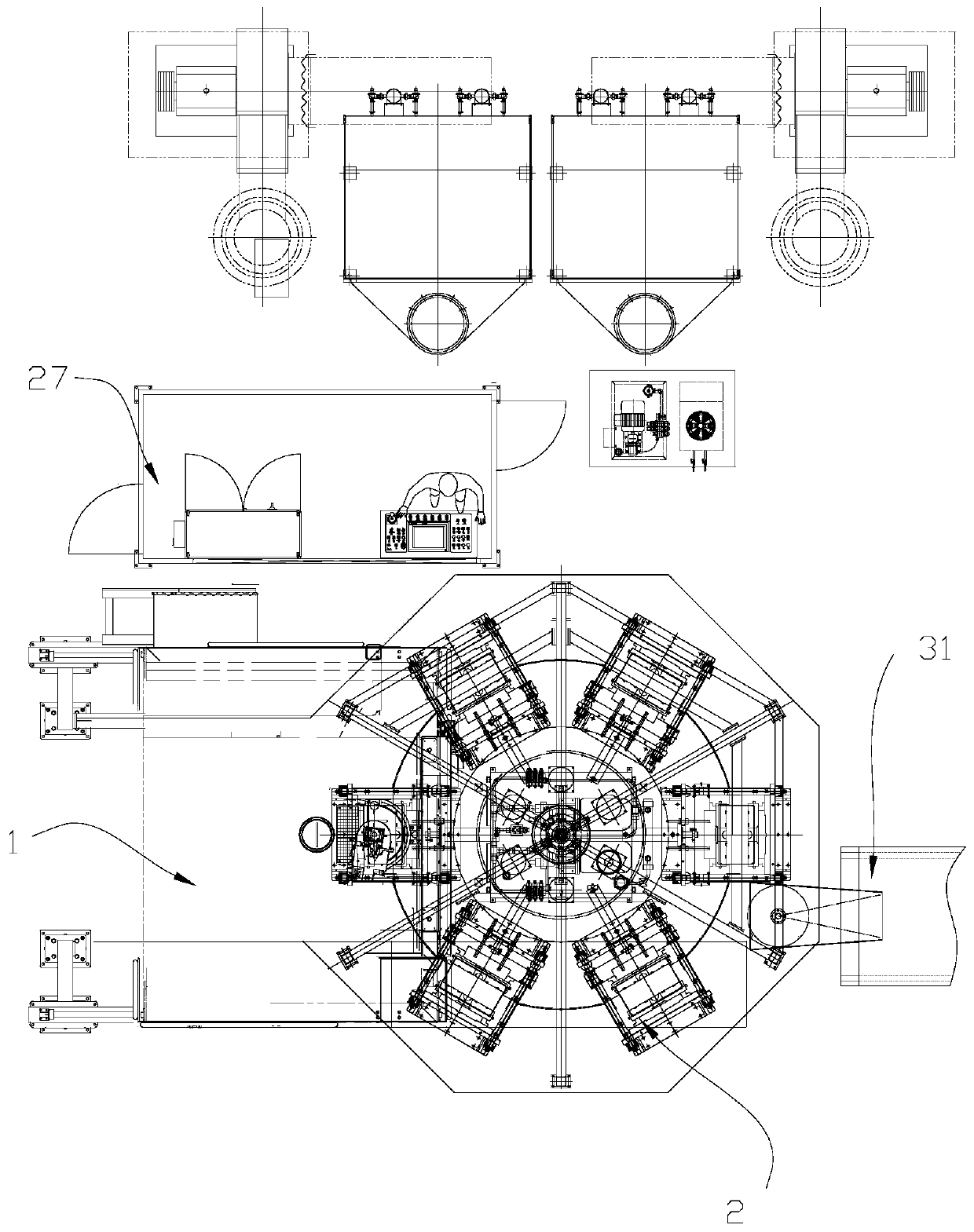

[0040] Reference Figure 1 to Figure 23 , The present invention is a fully automatic turntable mold casting production equipment, which includes an automatic thermal insulation casting machine 1, a six-station automatic turntable casting machine 2, a normalizing furnace 3, a casting conveyor belt 31, and an automatic screening and separating conveying mechanism 4.

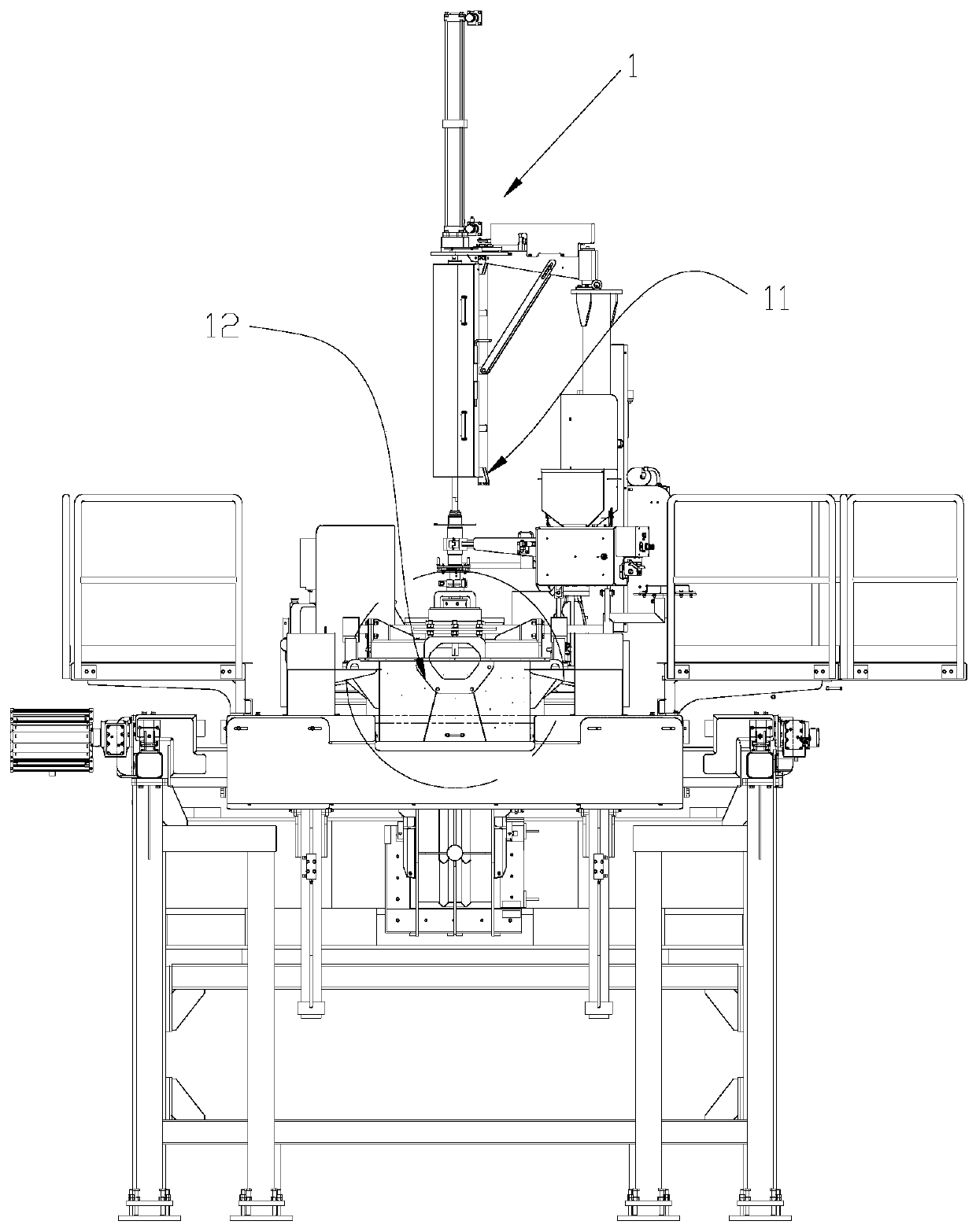

[0041] The automatic heat preservation type casting machine 1 includes a casting machine main body 11 and a temperature-increasing casting ladle 12 installed on the casting machine main body 11. Since the casting machines of the prior art are ordinary casting ladle, they do not have the function of active heat compensation. As time goes by, the temperature of the molten metal will drop, resulting in poor fluidity and metallographic changes, so it is not suitable for automated continuous casting , So the pouring ladle structure is improved. Specifically, the temperature-increasing casting ladle 12 includes a fire-proo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com