Clamp for welding of stud

A fixture and stud technology, which is applied in the field of stud welding fixtures, can solve the problems of high manual management cost, low yield rate, and low welding efficiency, and achieve the effects of standardization of welding process, improvement of yield rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

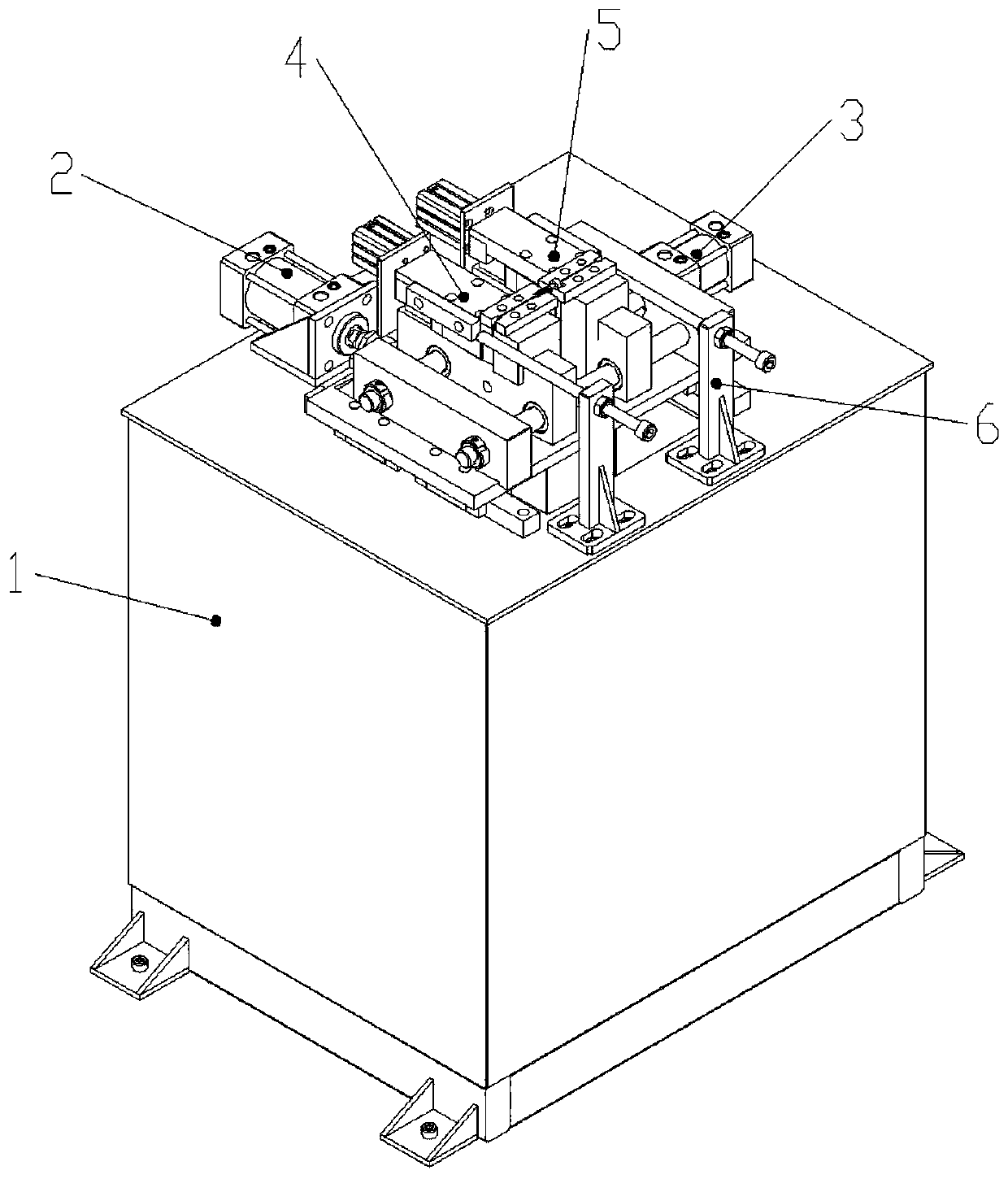

[0031] like figure 1 Shown is a perspective view of the present invention, including a fixed frame 1, a first mobile structure 2, a second mobile structure 3, a third mobile structure 4, a fourth mobile structure 5 and an adjustment structure 6, and the first mobile structure 2 is arranged on Directly above the fixed frame 1, the second mobile structure 3 is arranged directly above the first mobile structure 2, the third mobile structure 4 and the fourth mobile structure 5 are arranged side by side directly above the second mobile structure 3, and the adjustment The structure 6 is arranged on the upper edge of the fixing frame 1 .

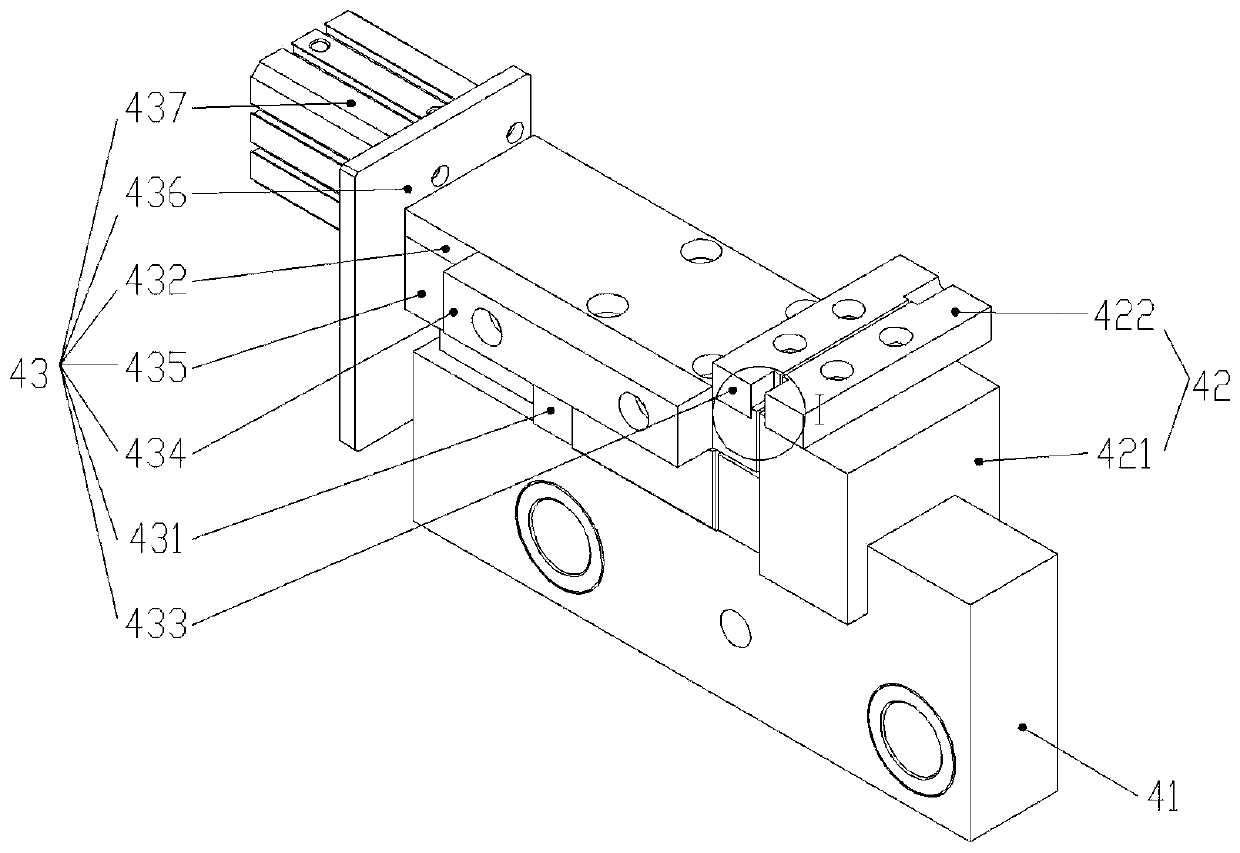

[0032] like figure 2 Shown is a perspective view of the third moving structure 4, including a first fixed seat 41, a first clamp fixing structure 42 and a first clamp moving structure 43, and the first clamp fixing structure 42 and the first clamp moving structure 43 are arranged side by side on On the first fixed seat 41; the first clamp fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com