Wood board surface coloring process

A technology of surface coloring and wood board, which is applied in wood processing equipment, wood treatment, manufacturing tools, etc., can solve the problem of single coloring, achieve the effects of reducing costs, realizing automatic fading, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

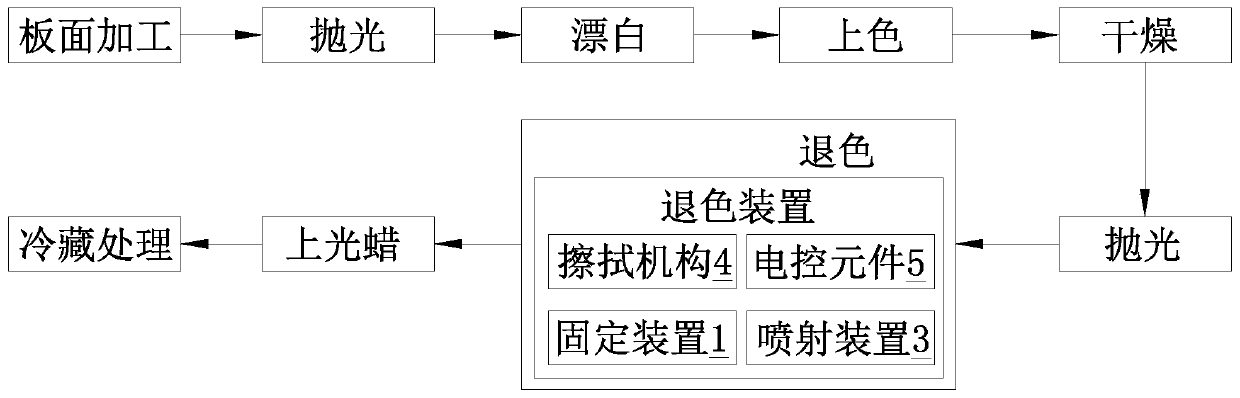

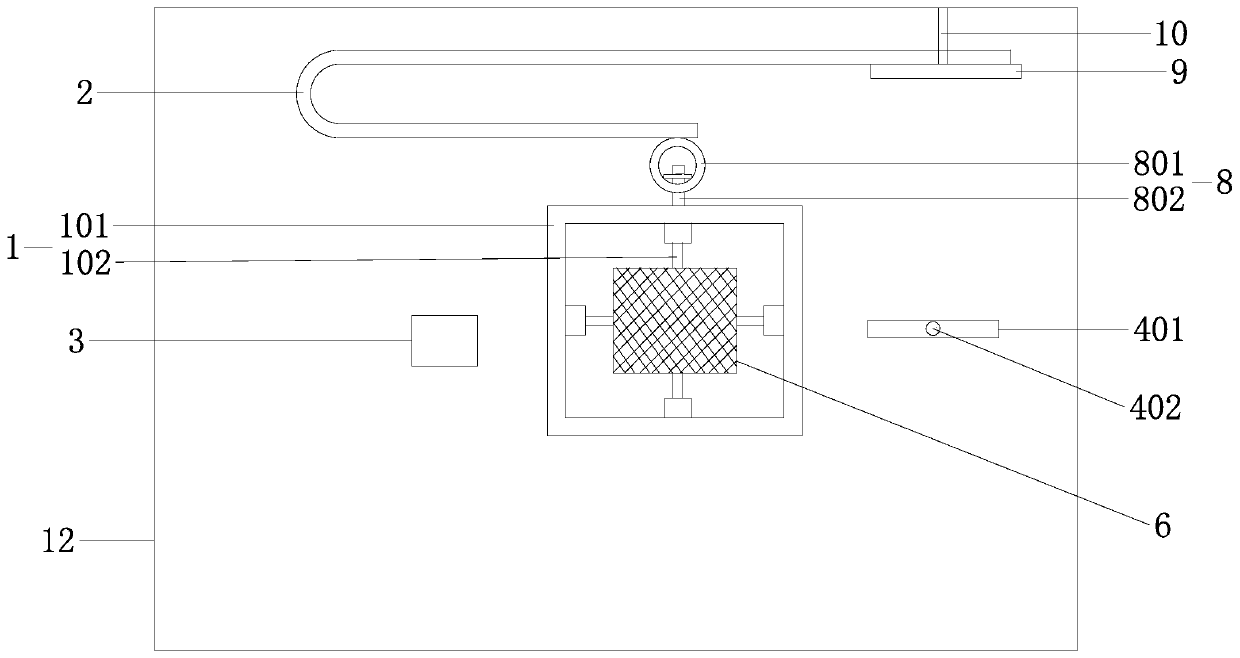

[0041] Such as figure 1 and figure 2 The wood panel surface coloring process shown here refers to firstly coloring the surface of the solid wood panel and then fading it, and processing a structure with alternating degrees of coloring on the panel surface to form the color difference effect of the decorative panel made of this solid wood panel , to enhance the three-dimensional effect of its surface, the process mainly includes:

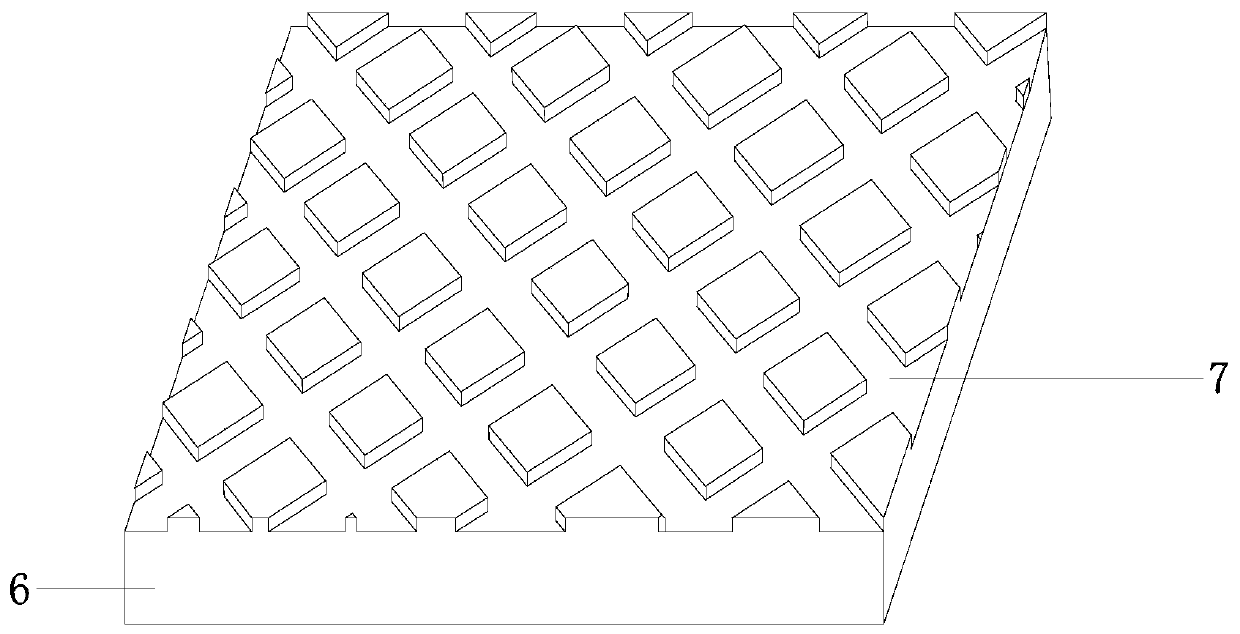

[0042] 1) Board surface processing: Cut the wood into a board shape of appropriate size, use a planer to cut out interlaced concave lines on the surface of the solid wood board, the concave lines can be distributed in a grid shape, and the height of the concave lines is lower than the surface of the wood board the height of;

[0043] 2) Polishing: Select 300-mesh coarse sandpaper to roughly grind the sliced solid wood board along the grain direction of its surface to reduce the roughness of the surface and remove large burrs on the surface;

[...

Embodiment 2

[0062] The present embodiment is different from Embodiment 1, and its difference is that described discoloration agent is set as paint stripper, and the paint stripper here utilizes to have osmotic swelling action easily to the paint covered, can effectively remove plank 6 surface paint coating.

[0063] The wiper 4012 is set as a soft felt cloth, which reduces the friction damage caused by the wiper 4012 to the solid wood board 6 , and has high economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com