Foam rotary forming machine

A molding machine and foam technology, used in household components, household appliances, other household appliances, etc., can solve the problems of high consumption of materials, low market acceptance rate, and high production cost, and can solve the problems of large land area, increased market acceptance rate, Crafting the effect of reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the principle and structure of the technical solution of the present invention, one embodiment of the present invention will be described below in conjunction with the contents of the accompanying drawings.

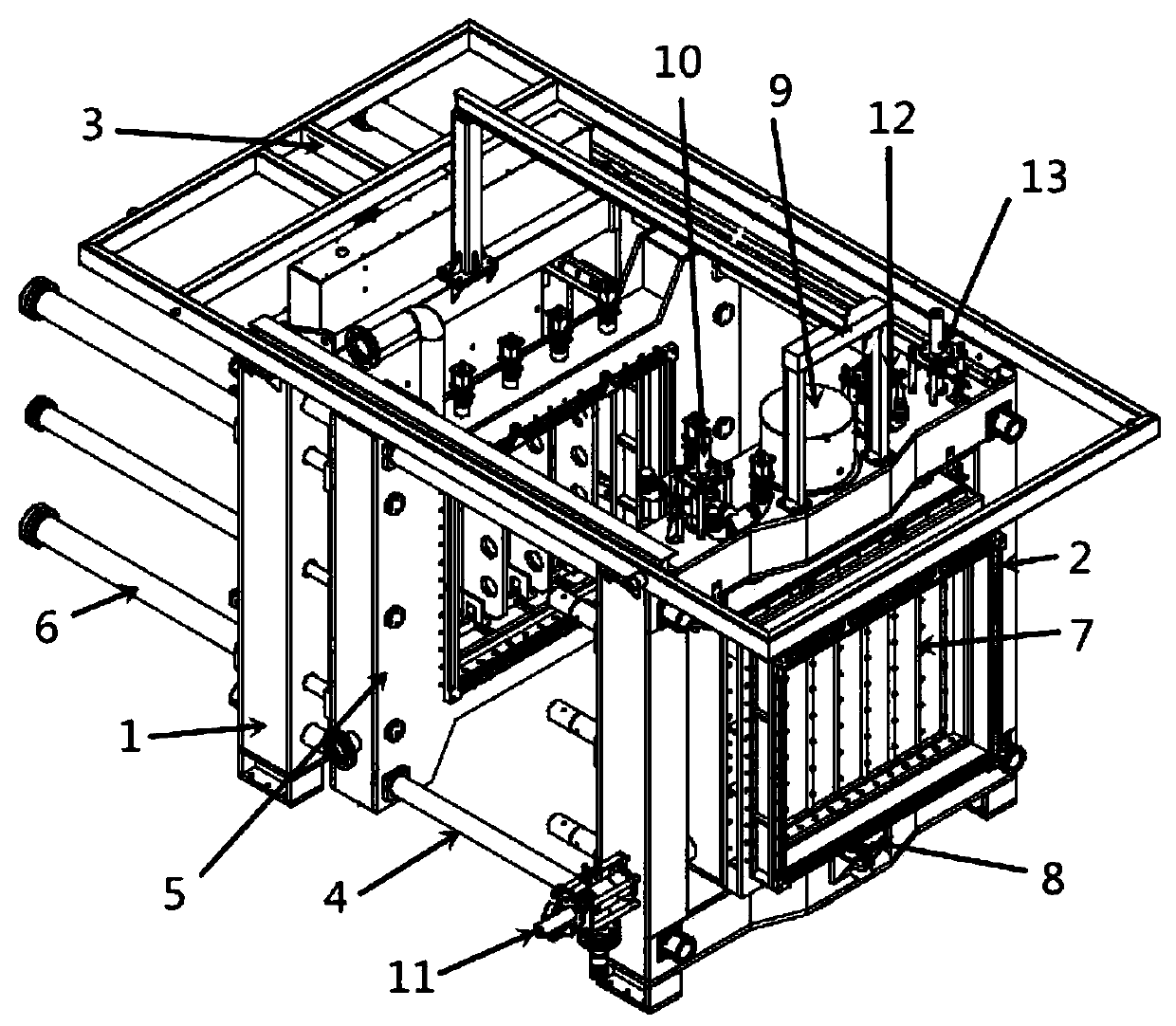

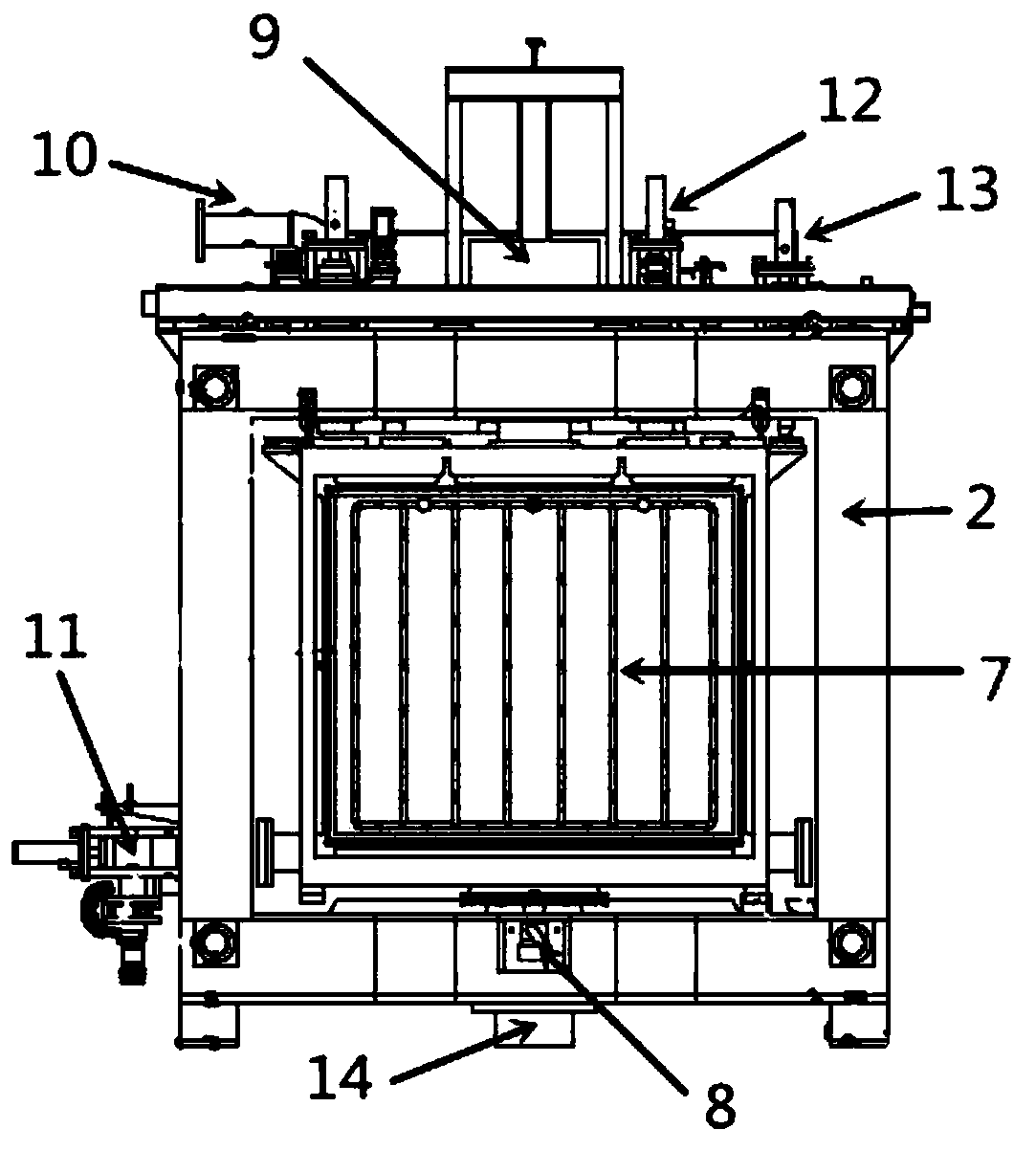

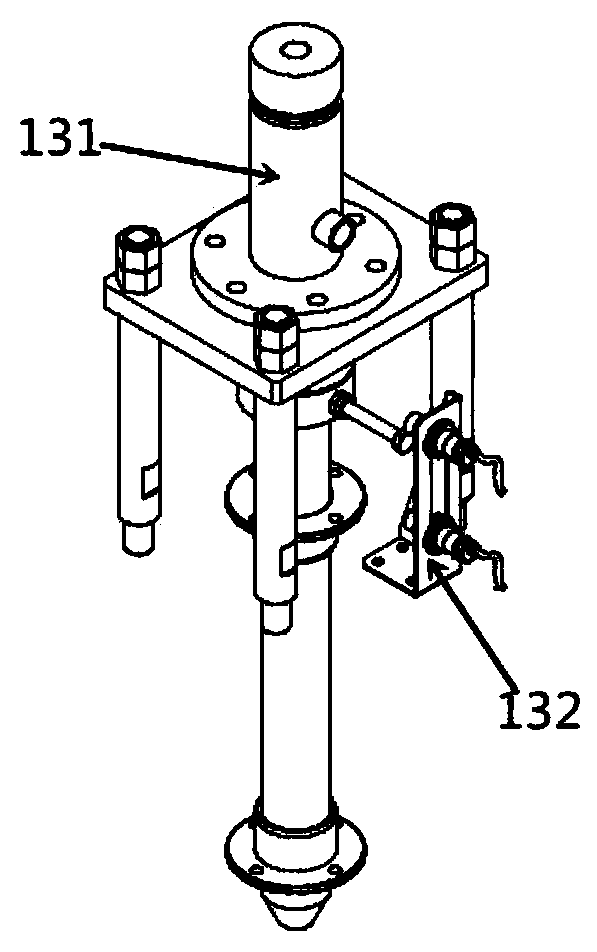

[0024] like Figure 1 to Figure 6 As shown, the foam rotary molding machine of this embodiment includes a rear frame 1, a front frame 2, a fixed frame 3, a guide rod 4, a movable mold machine 5, a movable mold push rod 6, and a double-chamber water tank 7 , water tank motor 8, rotary encoder 9, enter steam telescopic mechanism 10, drainage telescopic mechanism 11, enter water telescopic mechanism 12, fine positioning mechanism 13, rotating main shaft 14. Among them, the steam inlet telescopic mechanism 10 includes a steam push rod 101, a steam switch 102, an inner tooth elbow 103, a diffuser valve 104, an outer tooth straight-through 105, a tee 106, and an undercut 107; the drainage telescopic mechanism 11 includes a drainage push Rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com