Processing method of finished holes of circuit board with inner-layer copper thickness of more than 420 micrometers

A technology of inner layer copper thickness and processing method, which is applied in metal processing and other directions, can solve the problems that copper wire cannot be quickly dissipated and broken, CNC drilling machine is stuffy, and tool is broken, so as to solve the problem of inner layer pad falling off, drilling The effect of high hole feed rate and better chip breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

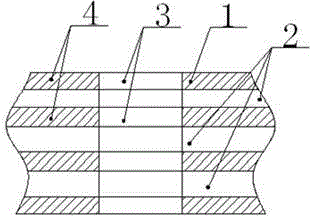

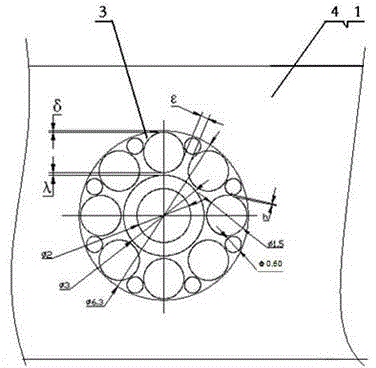

[0015] Embodiments, with reference to the accompanying drawings, a hole-forming method for a circuit board with an inner copper thickness of 420um or more, comprising a circuit board 4 with an inner copper thickness of 420um or more, bonded together by a multilayer copper foil layer 1 and a core material layer 2 , the method for processing the finished hole 3 on the circuit board 4 with an inner layer copper thickness of 420um or more is characterized in that the following steps are taken:

[0016] a. Choose a φ0.60mm drill bit, drilling speed 60-75krpm, feed 152-180ipm, return speed 1000ipm, drill multiple φ0.60mm holes evenly around the finished hole 3; cross-hole pause time 0ms; φ0. The distance between the 60mm hole and the finished hole 3 is δ, δ=30~50um;

[0017] b. After drilling φ0.60mm holes, select φ1.50mm drill bit, drilling speed 20~30krpm, feed 150~160ipm, return speed 1000ipm, drill multiple φ1.50mm holes between φ0.60mm holes, φ1. The distance between the 50m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com