Printing and laminating mechanical device

A mechanical device, laminating machine technology, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problems that small enterprises cannot provide, strict production conditions, product quality impact, etc., to reduce the possibility of , The effect of improving quality and reducing the impact of workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

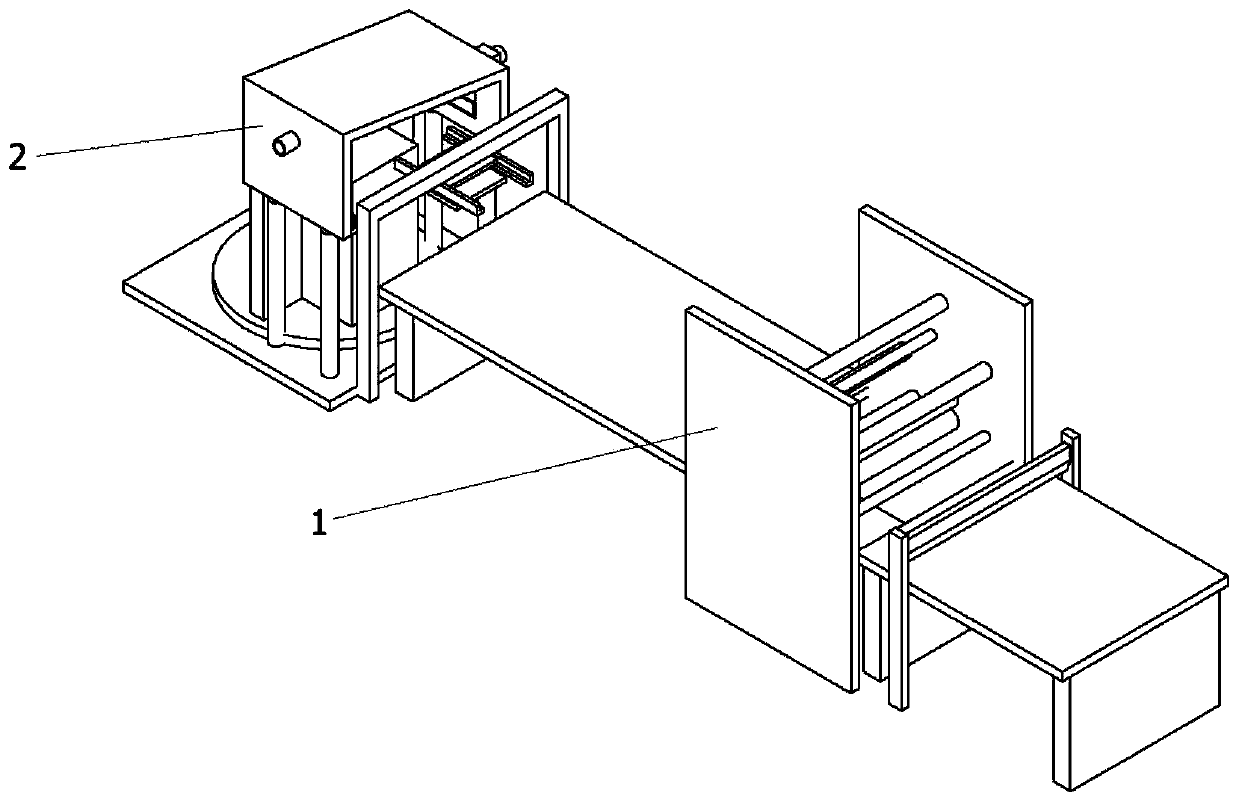

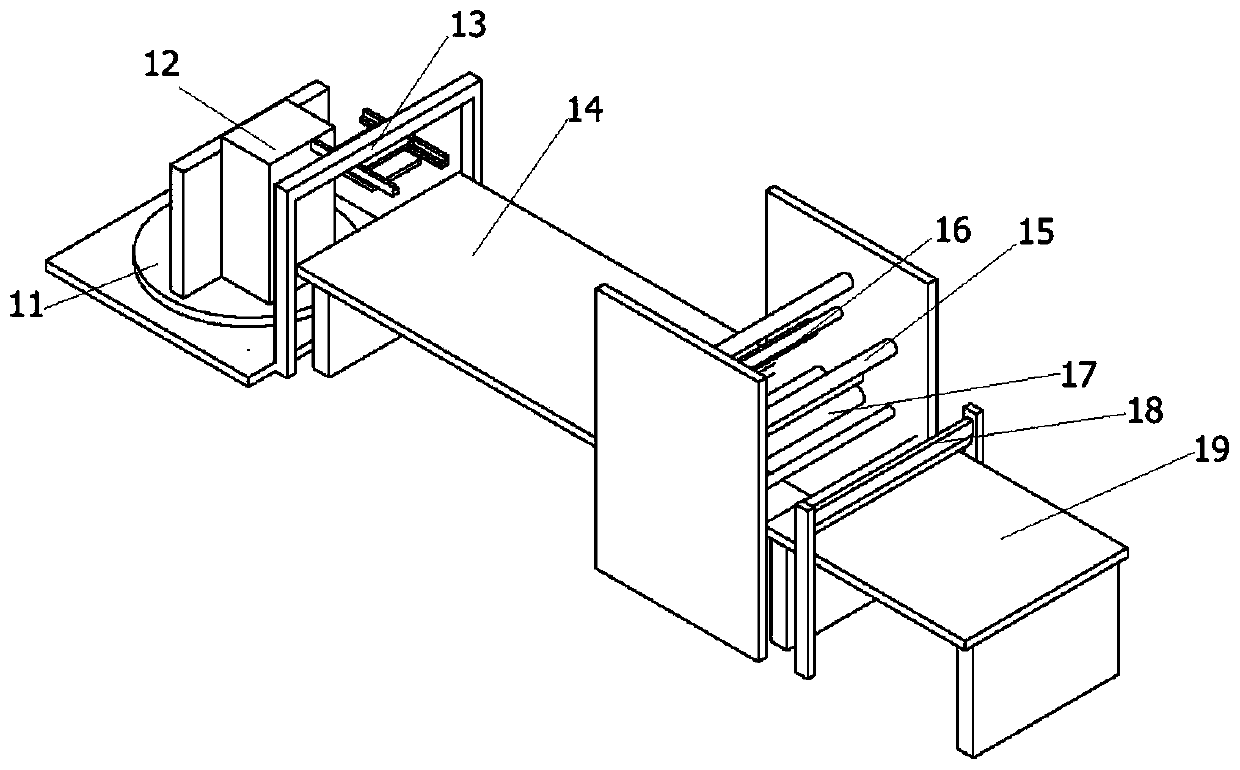

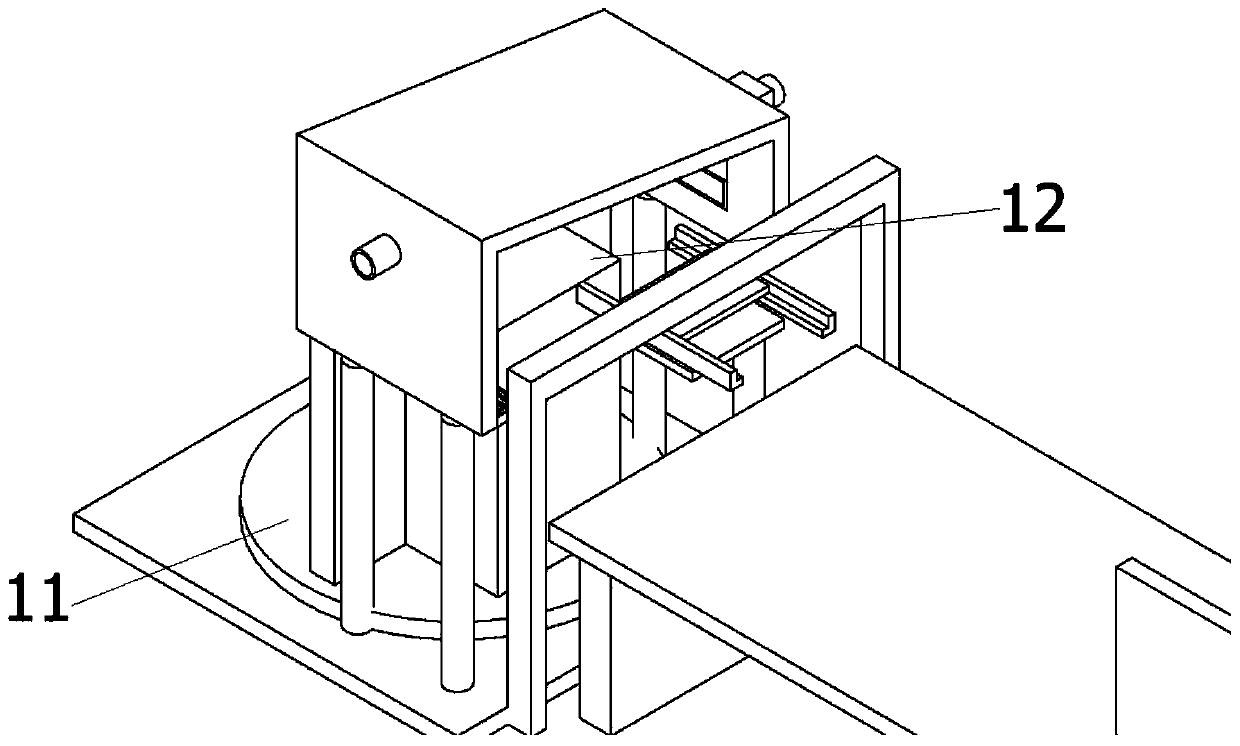

[0021] as attached Figures 1 to 8 A printing and laminating mechanical device shown includes a laminating machine 1 and a dust removal and dehumidification device 2; the dust removal and dehumidification device 2 is straddled above the paper feeding table 11; the dust removal and dehumidification device 2 includes an air intake duct 21 and an air outlet pipe 22; the air inlet pipe 21 and the air outlet pipe 22 are respectively located on both sides of the dust removal and dehumidification device 2, and a hot air flow is formed between the air inlet pipe 21 and the air outlet pipe 22.

[0022] The laminating machine 1 includes a paper feeding platform 11, a paper conveying device 13, a conveyor belt 14, a film conveying device 15, an upper rubber roller 16, a pressing roller 17, a cutting device 18 and a product output belt 19; 11 includes a circular rotating lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com