Patents

Literature

35results about How to "Reduce drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

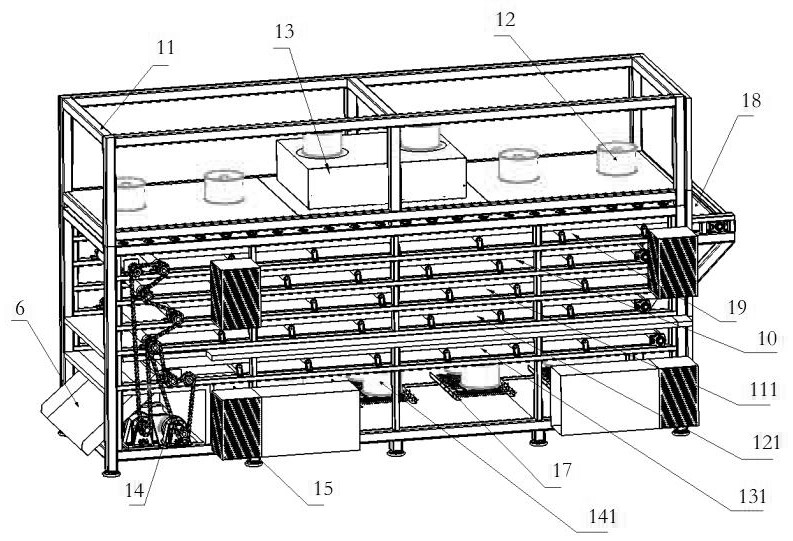

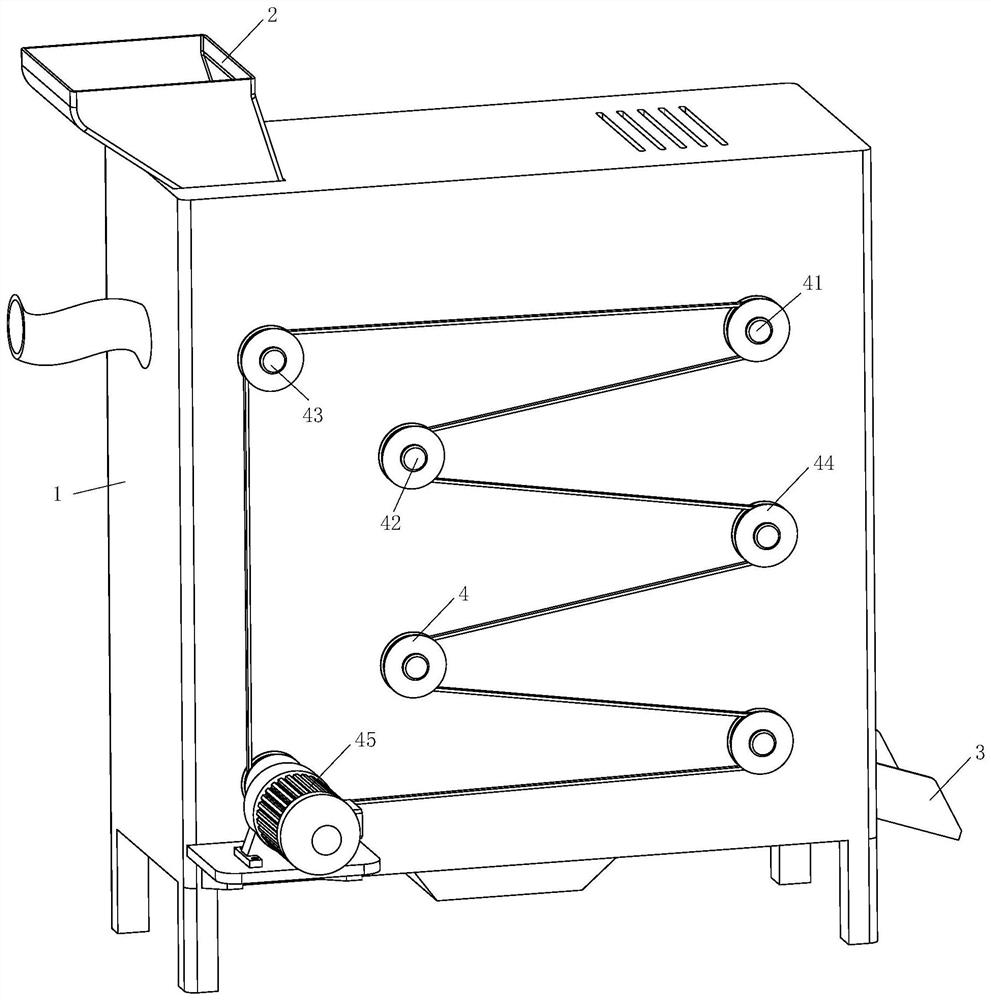

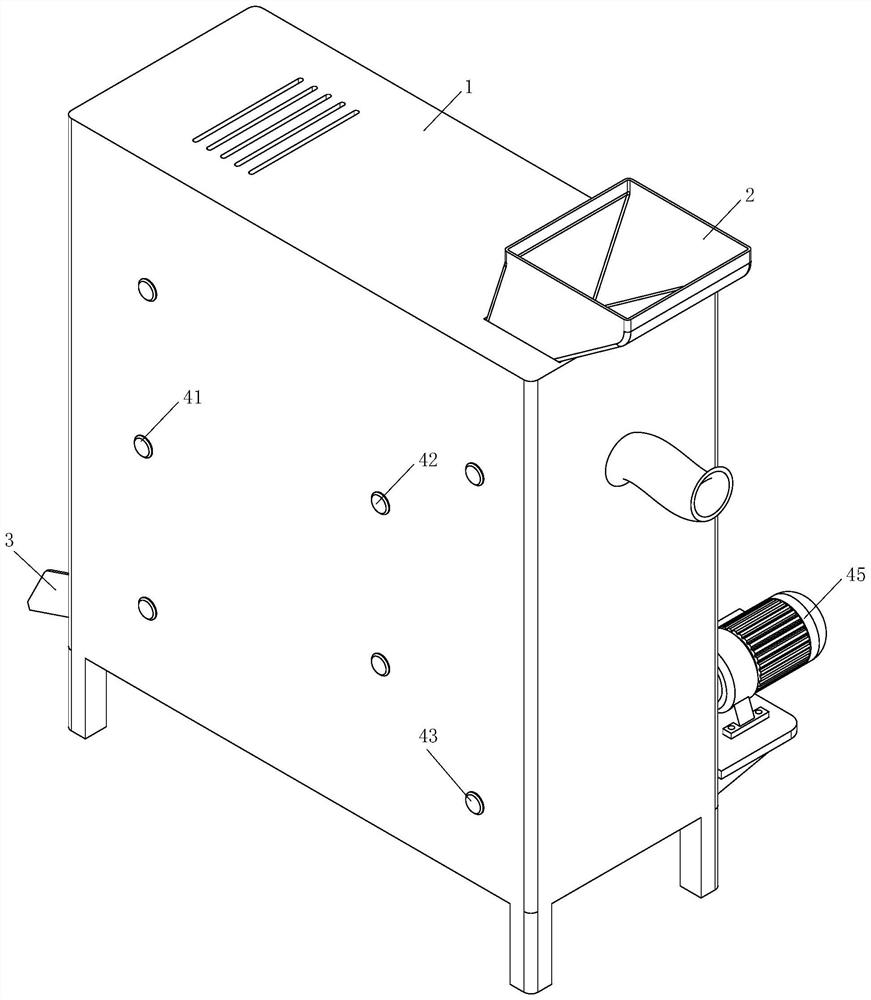

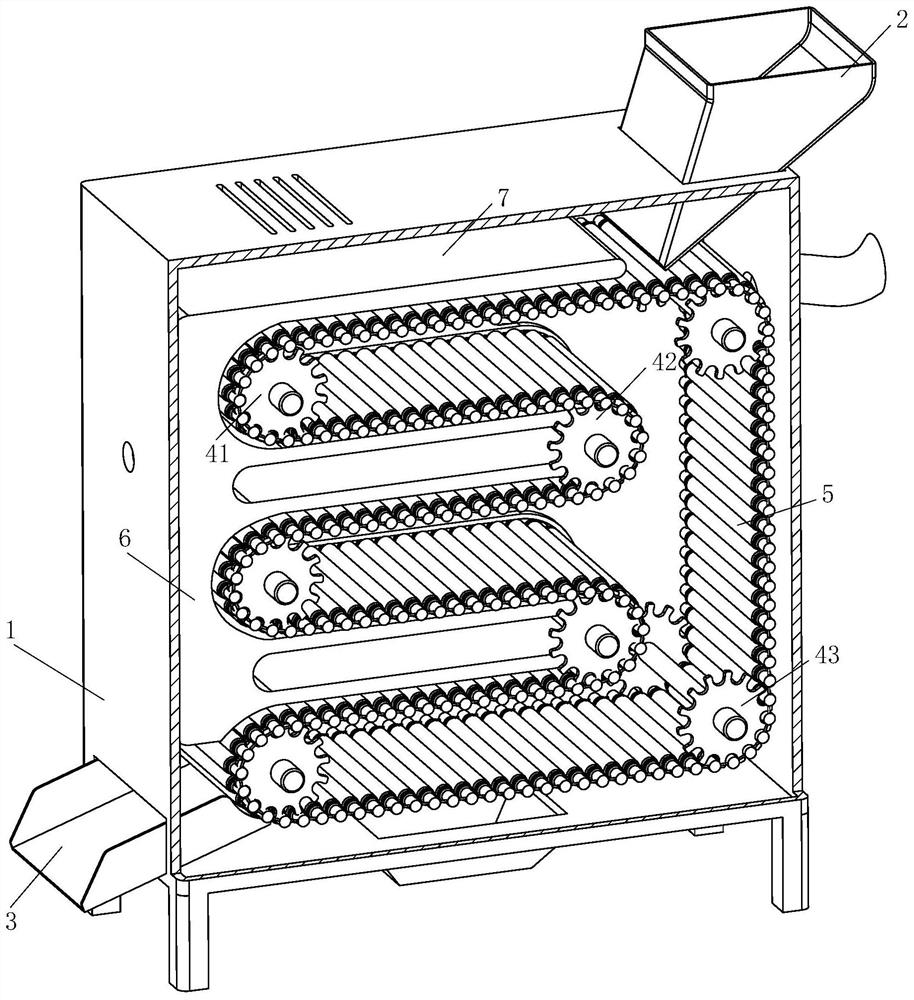

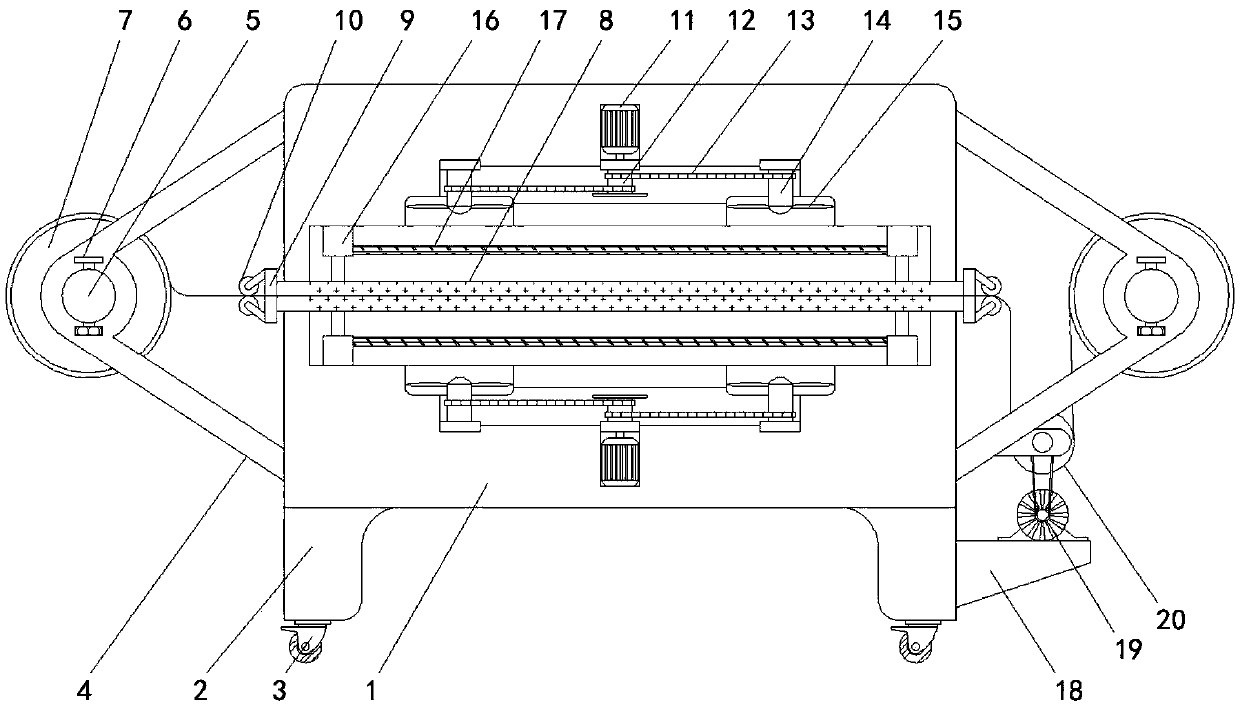

Cloth multi-layer washing and drying integrated equipment

ActiveCN104153143ALow clearIncrease concentrationSucessive textile treatmentsTextile treatment machine arrangementsPulp and paper industryUtilization rate

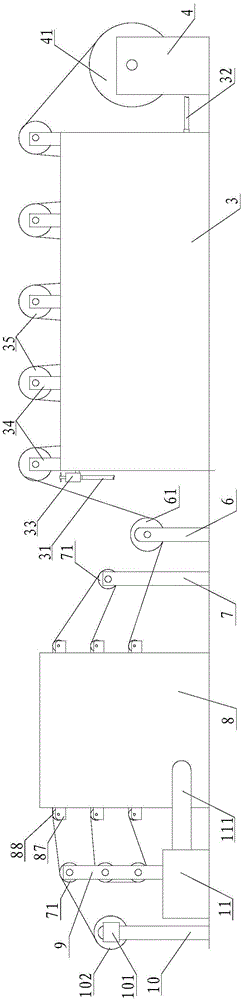

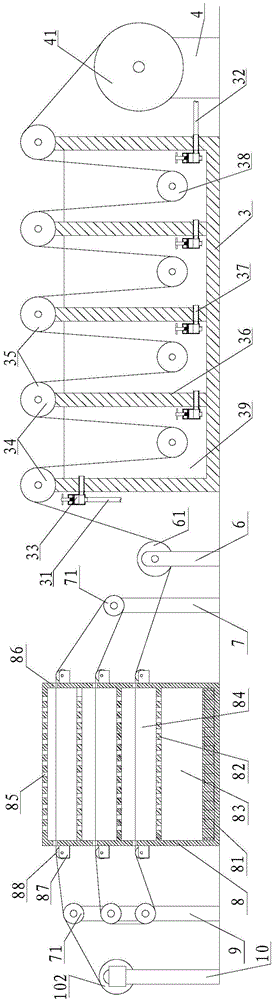

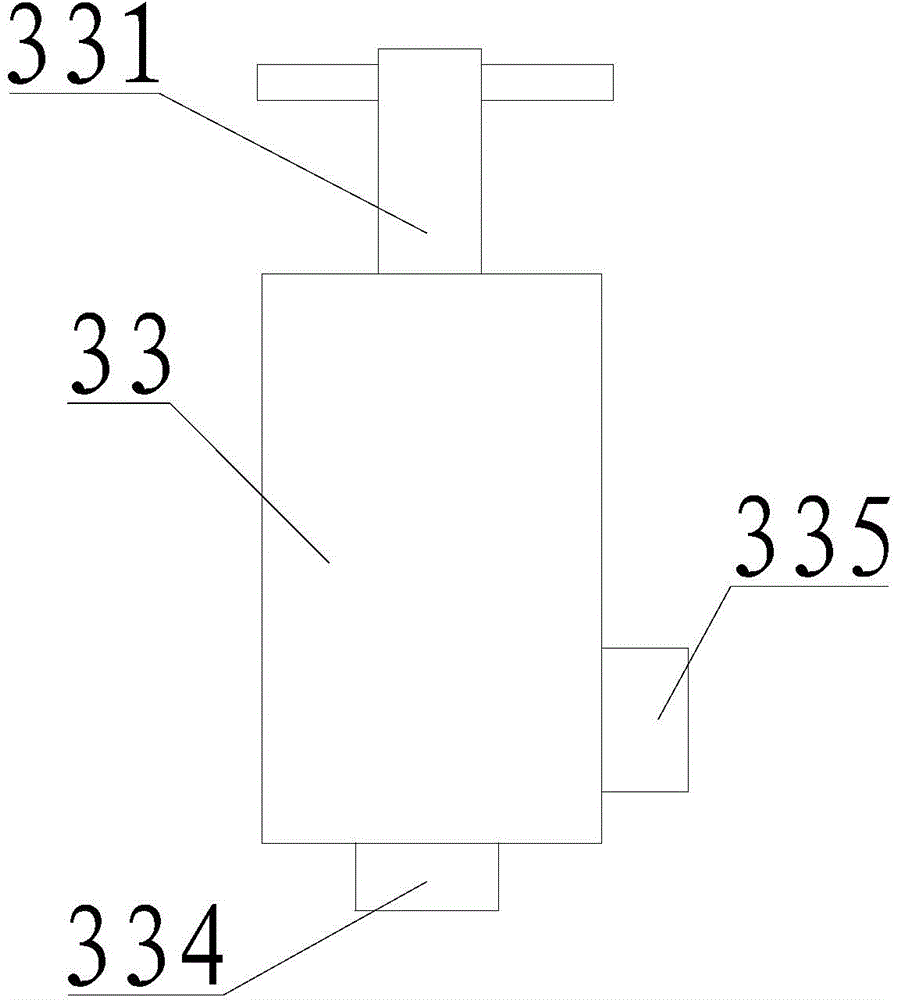

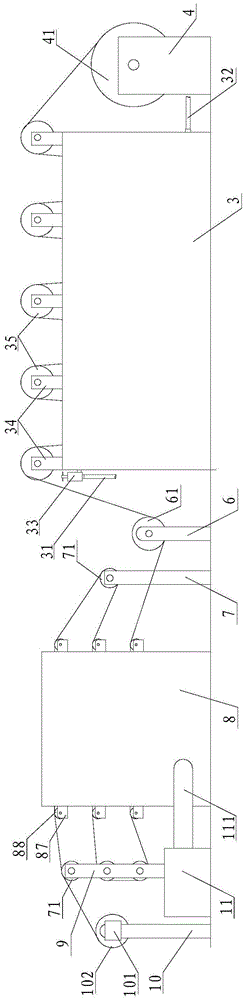

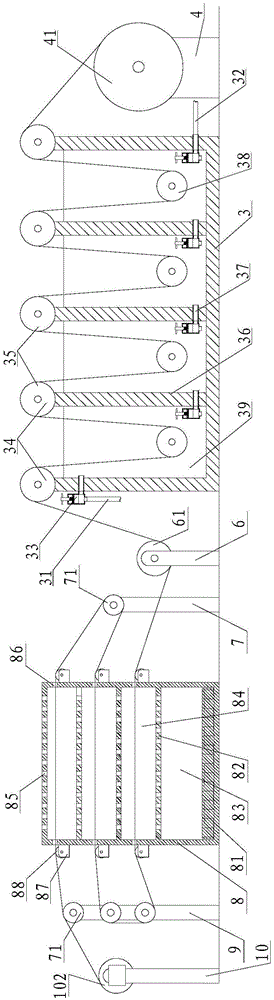

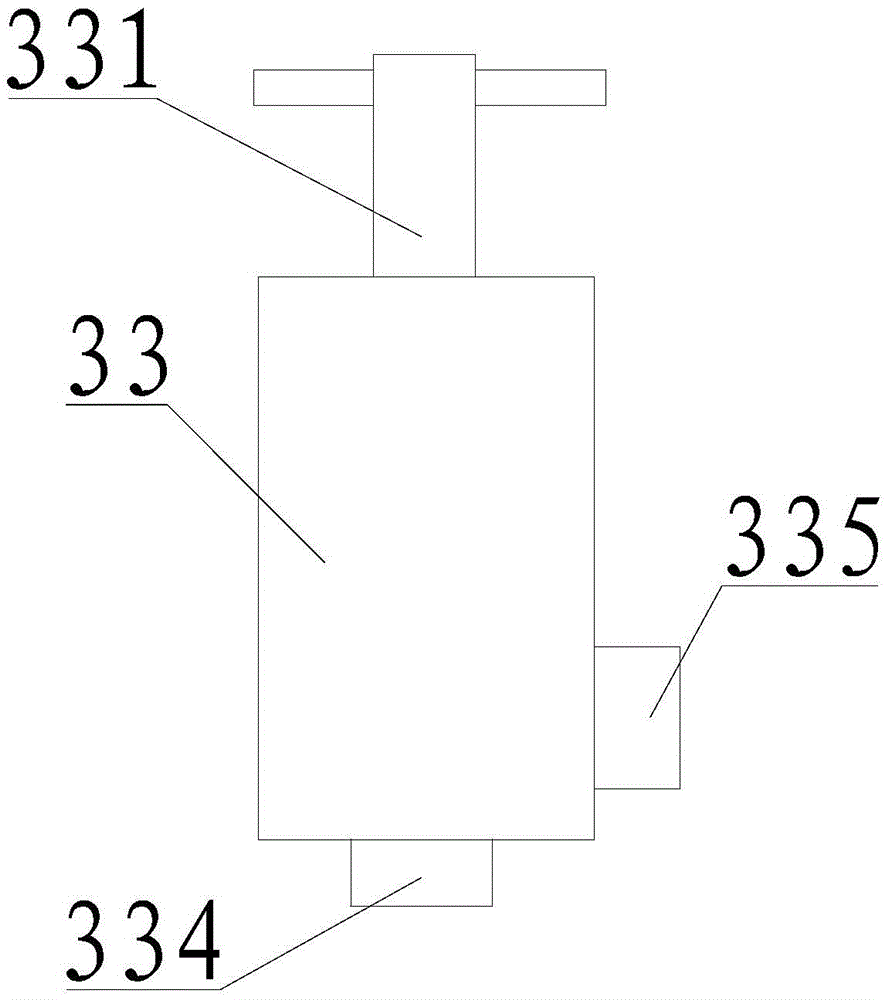

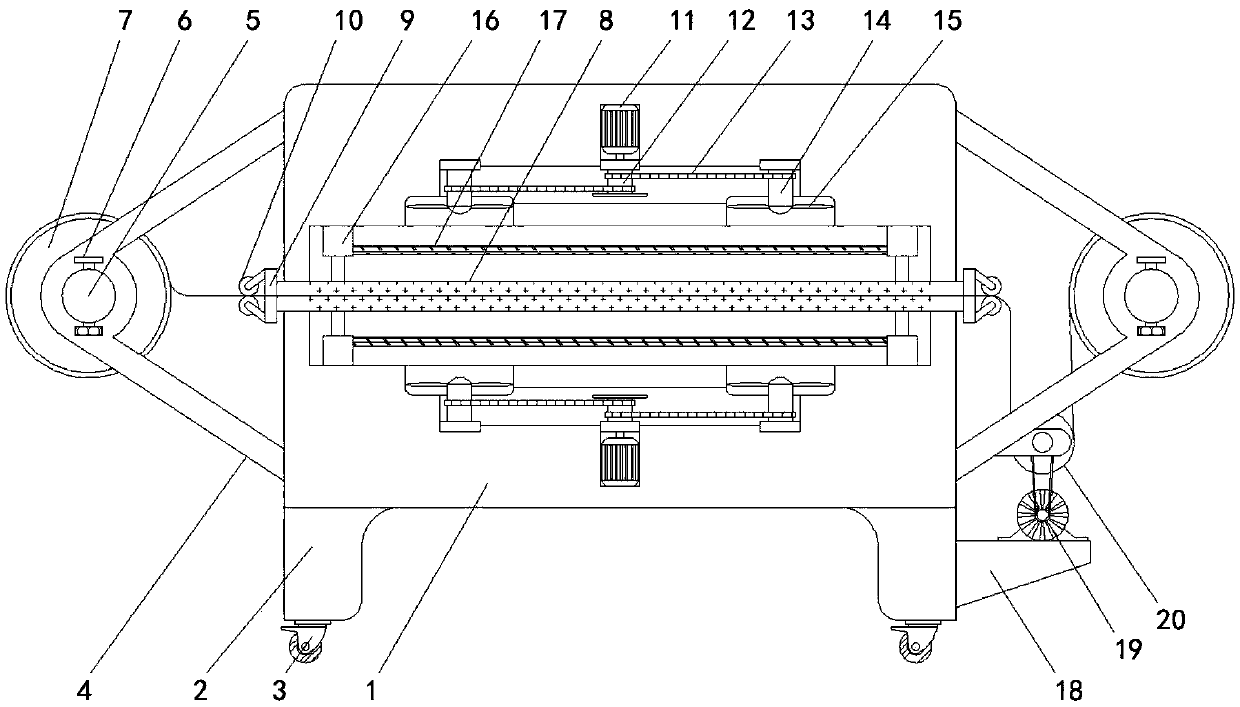

The invention discloses cloth multi-layer washing and drying integrated equipment which comprises a water tank, a cloth unwinding roller support, regulating switches, a transfer roller support, a front supporting roller support, a drying box, a rear supporting roller support and a fan. A plurality of temperature layering plates are arranged in the drying box and enable the drying box to be divided into an electric heating chamber and a plurality of drying chambers, the two sides of each drying chamber are provided with cloth openings respectively, a plurality of vent holes are formed in the temperature layering plates, the fan is connected with the electric heating chamber through a wind pressure pipe, the inner portion of the water tank is divided into a plurality of washing chambers through partition plates, a series flow opening is formed between every two adjacent washing chambers, the corresponding regulating switches are arranged on the series flow openings, the left end and the right end of the water tank are provided with a water inlet and a water outlet respectively, and the corresponding regulating switches are arranged on the water inlet and the water outlet respectively. The cloth multi-layer washing and drying integrated equipment can complete cloth washing and drying in sequence, and is good in washing effect, high in water utilization rate and high in drying efficiency, and meanwhile the cloth multi-layer washing and drying integrated equipment is simple in structure and low in investment cost.

Owner:XINCHANG COUNTY HENGDA CLOTHING MFG

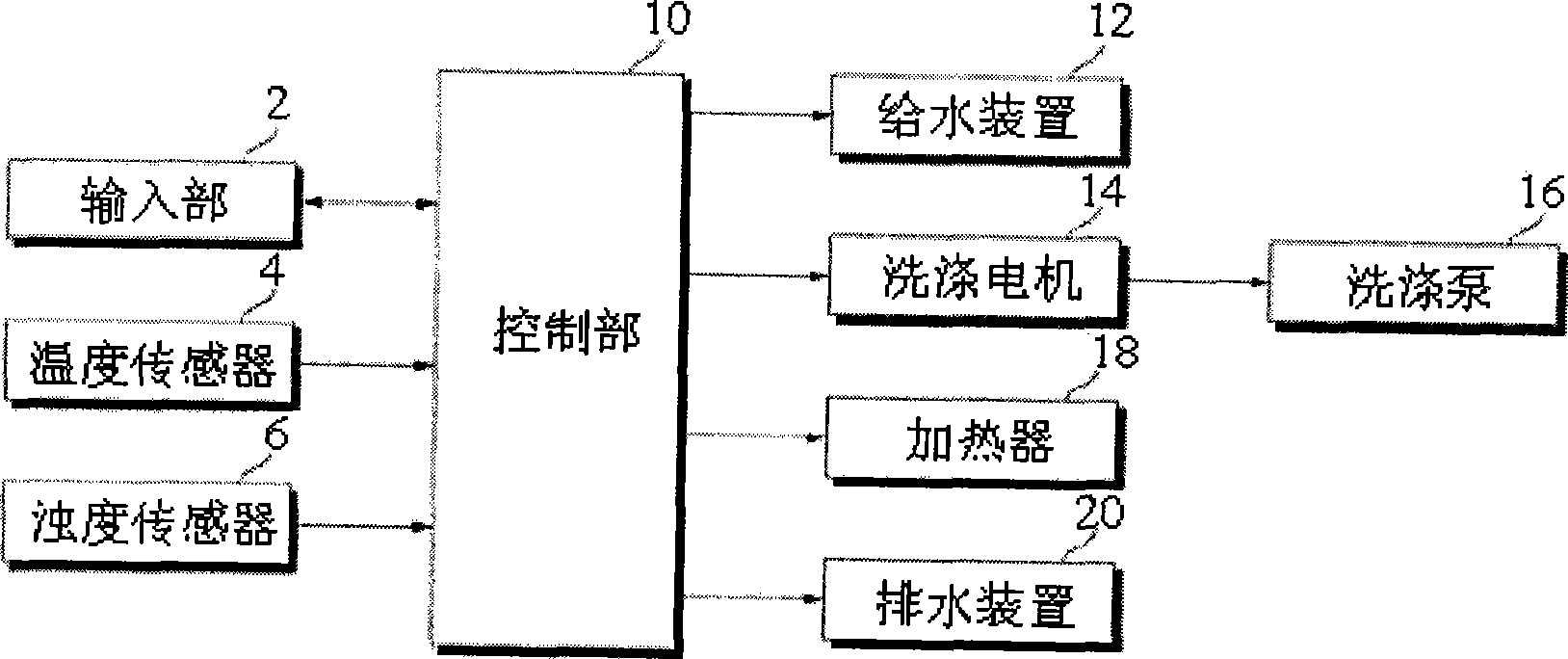

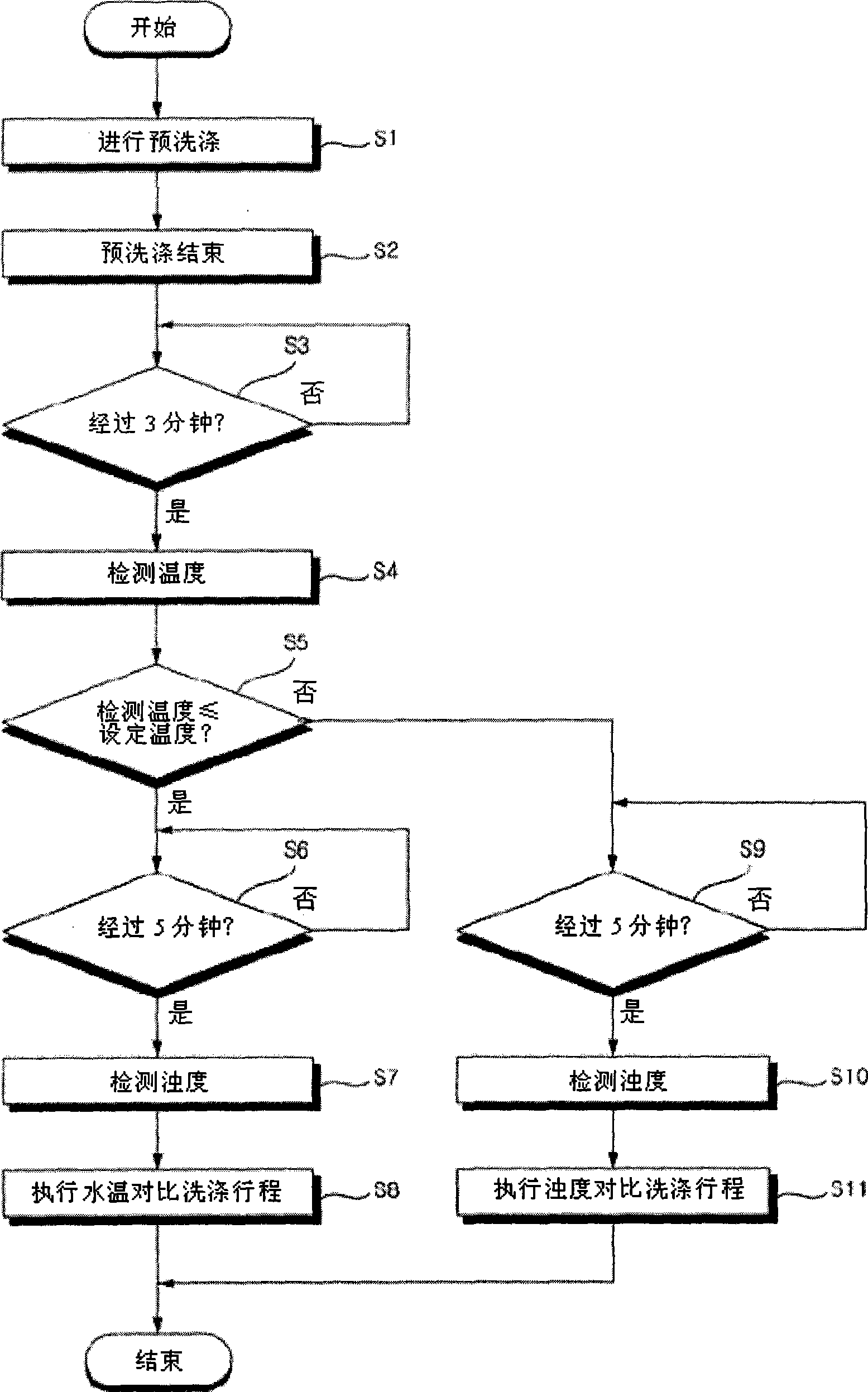

Dishwasher and control method thereof

InactiveCN101444411AReduced wash performanceReduce drying effectTableware washing/rinsing machine detailsProgramme control in sequence/logic controllersWater useTurbidity

The present invention relates to a dishwasher and a control method thereof, wherein the dishwasher includes a feedwater device for supplying washing water from outside; a water collection tank for storing the washing water supplied from the feedwater device temporarily; a washing tank for washing dishes using the washing water supplied to the water collection tank; a temperature sensor mounted in one of the water collection tank and the washing tank for detecting the temperature of the washing water; a turbidity sensor mounted in the water collection tank for detecting the turbidity of the washing water; and a control part for controlling the washing journey differently according to signals transmitted by the temperature sensor and the turbidity sensor. The invention detects the temperature of the washing water using the temperature sensor, the control part controls the washing journey according to the different temperature of the washing water, and sets a washing journey suitable for the temperature of the washing water, such that it is able to prevent washing performance and drying performance from reducing and shorten washing time when the temperature of the washing water is lower.

Owner:NANJING LG PANDA APPLIANCES

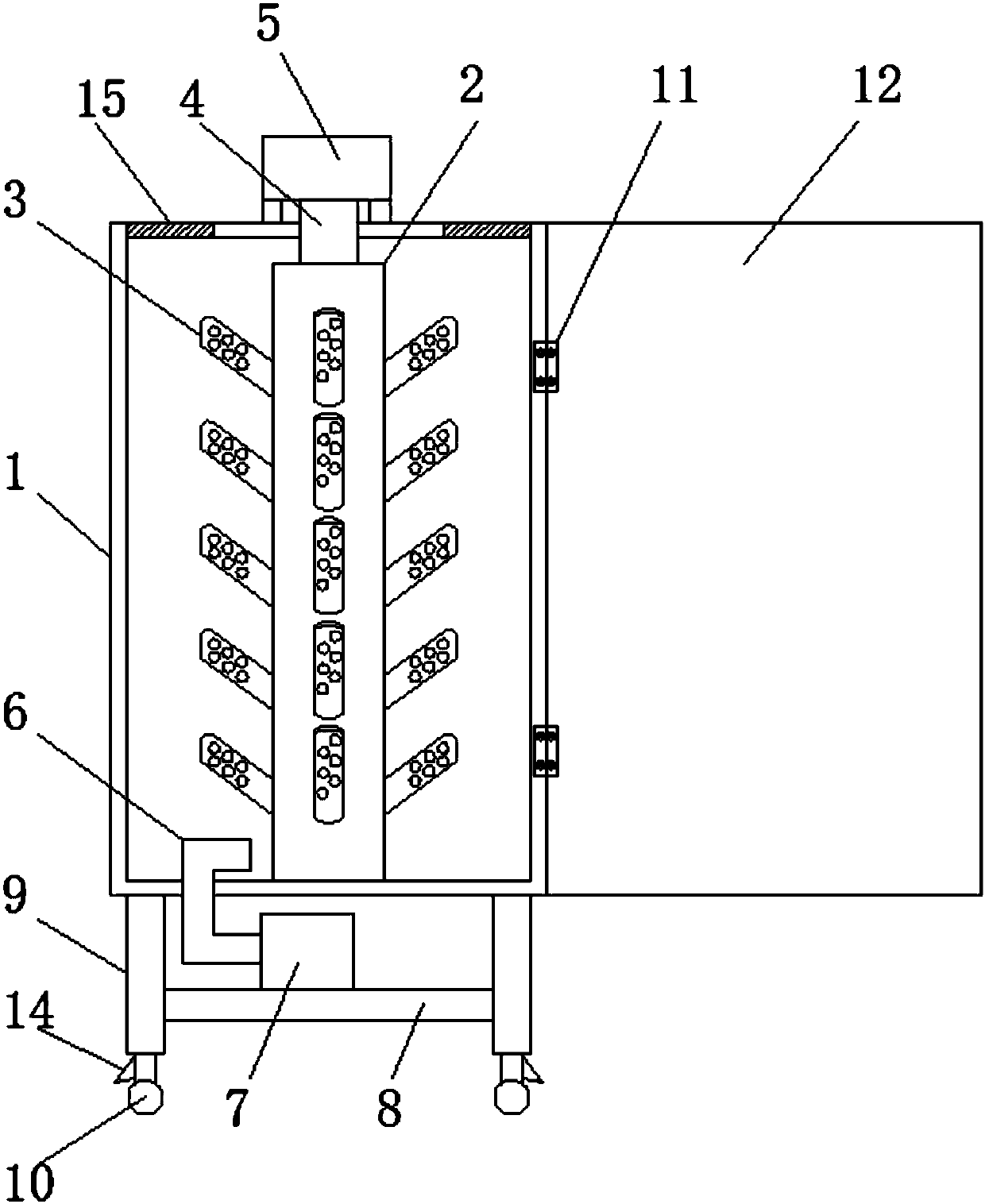

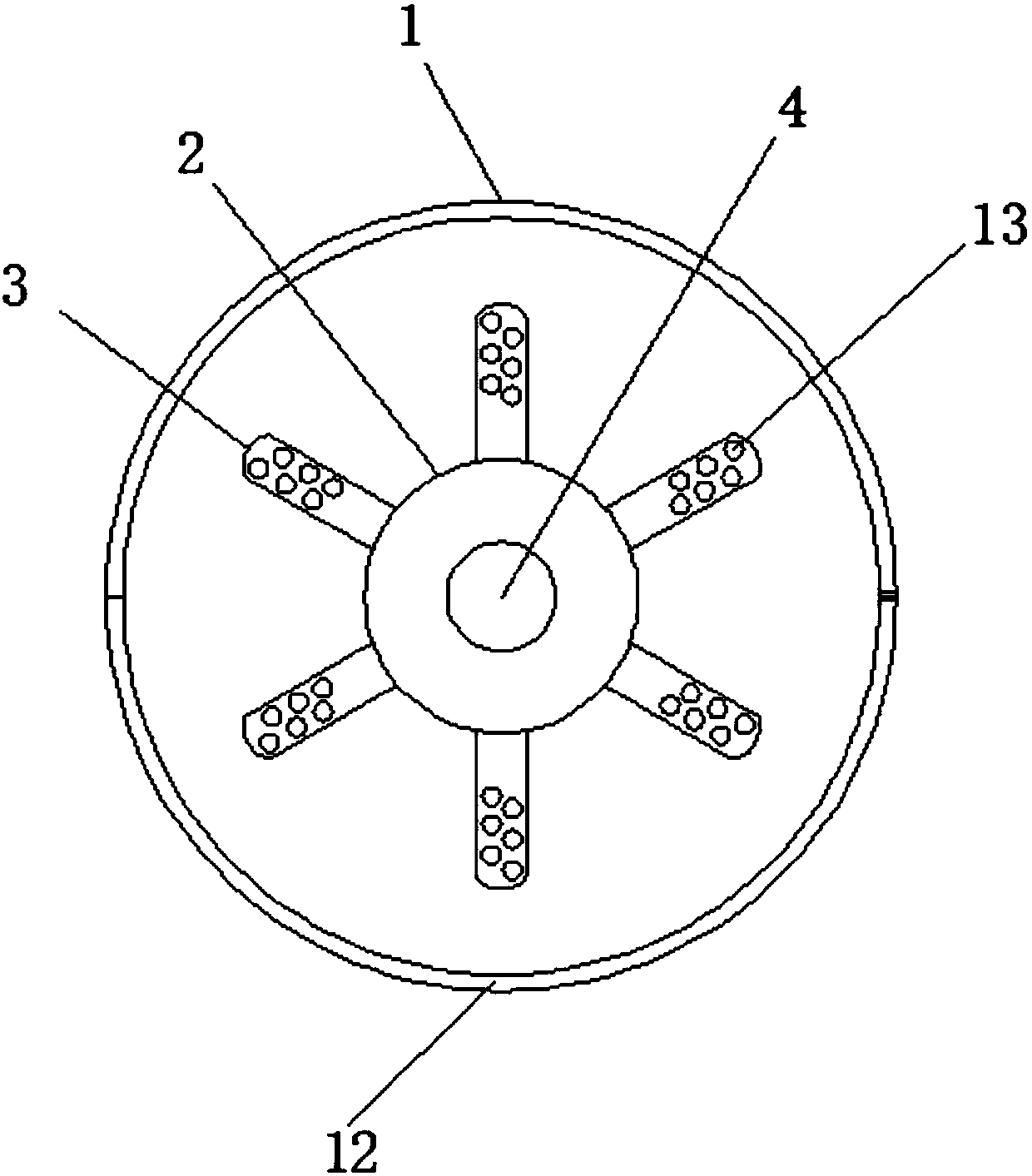

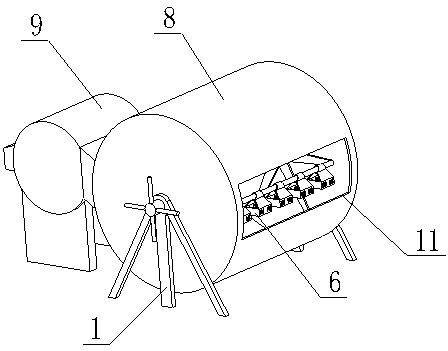

Convenient-moving and good-drying-effect drying machine for shoemaking

InactiveCN107702449AEasy to moveImprove drying effectDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention discloses a convenient-moving and good-drying-effect drying machine for shoemaking. The machine comprises a drying box, wherein a blow dryer is fixedly connected to the inner bottom endof the drying box; a plurality of shoe hanging racks are fixedly connected to the side surface of the blow dryer; a first air inlet tube is fixedly connected to the upper surface of the blow dryer; one end, far away from the blow dryer, of the first air inlet tube, passes through the top part of the drying box and then is fixedly connected to a first hot-air blower; a second air inlet tube passesthrough one side of the bottom part of the drying box; a second hot-air blower is fixedly connected to one end, far away from the drying box, of the second air inlet tube. The convenient-moving and good-drying-effect drying machine for shoemaking has the advantages of being simple in structure, convenient to use, convenient to move, and capable of massively and quickly drying, so that the drying efficiency of shoemaking is improved; and the problem that the drying machine in the prior art cannot be used for massively drying and easily leads to inconsistent speeds of inner drying and outer drying of shoes, resulting in the influence on overall glue drying speed and even the influence on shoes quality, as well as the problem of inconvenient moving, can be solved.

Owner:江苏润天服饰有限公司

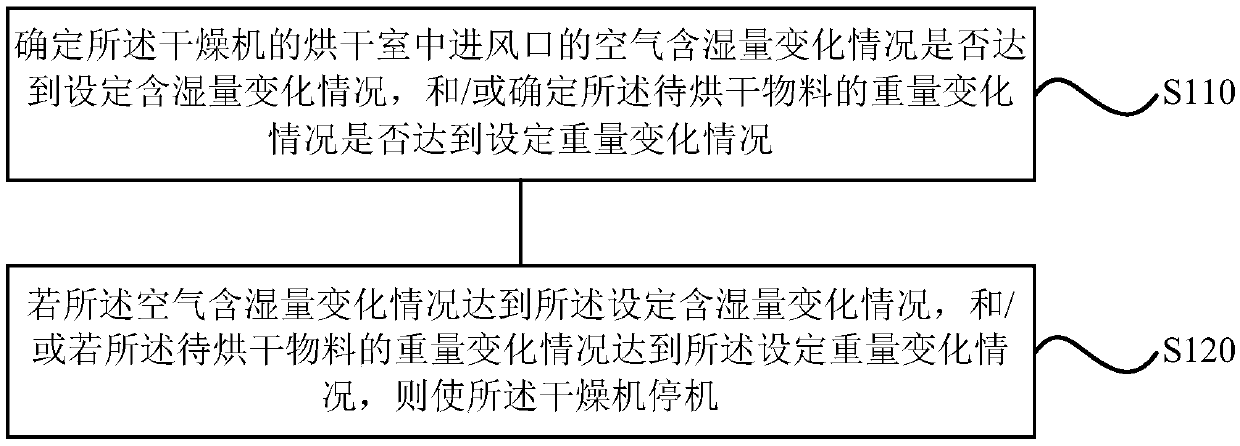

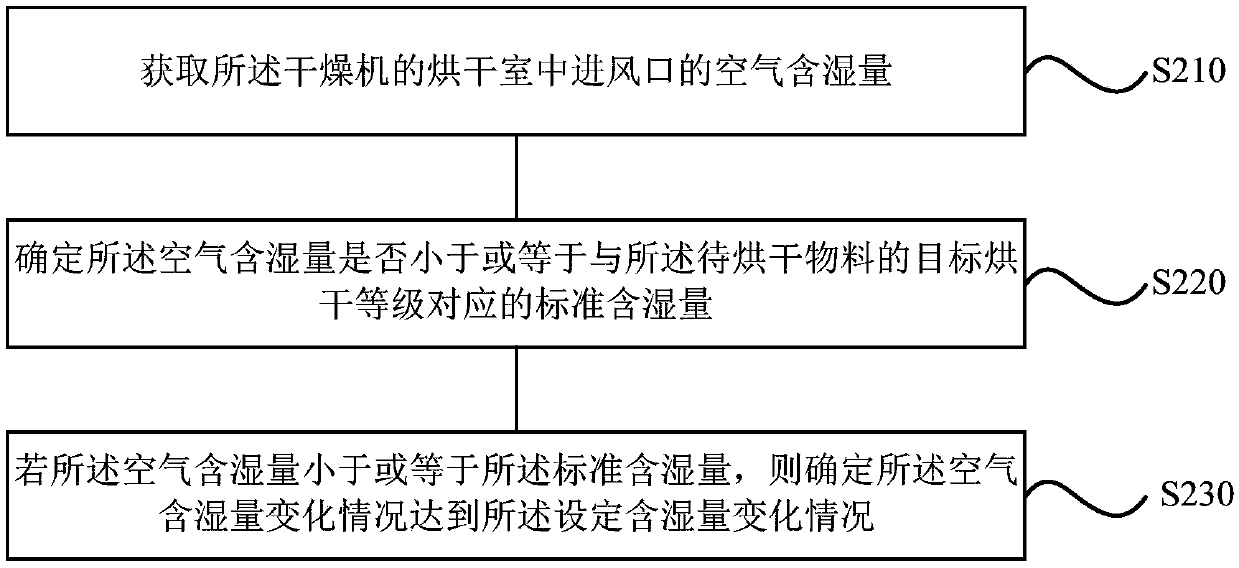

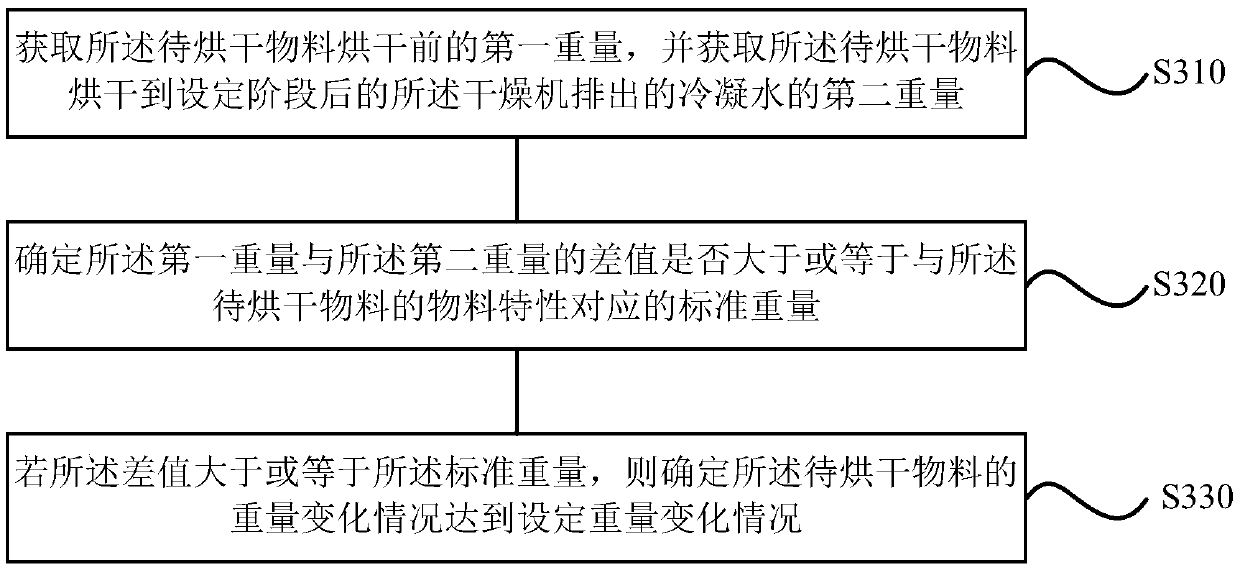

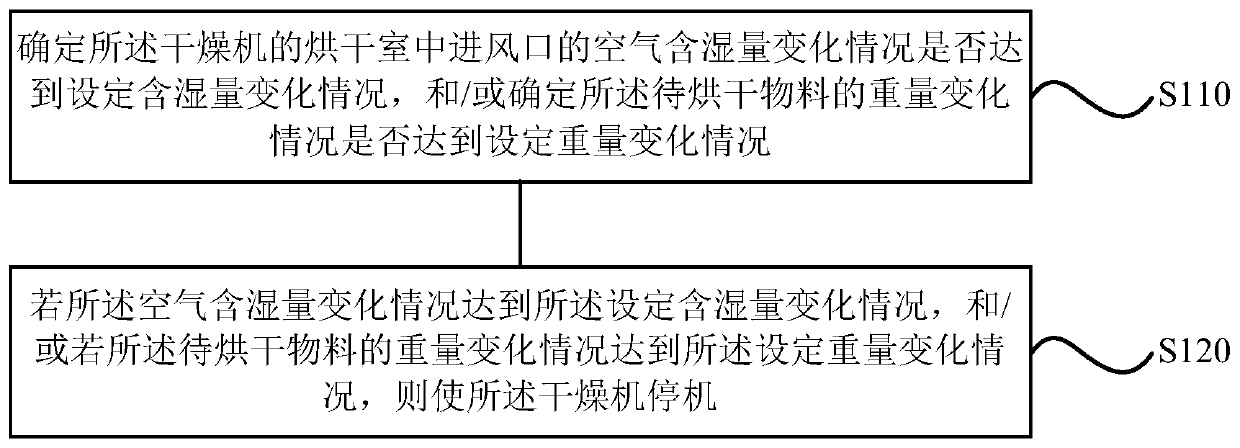

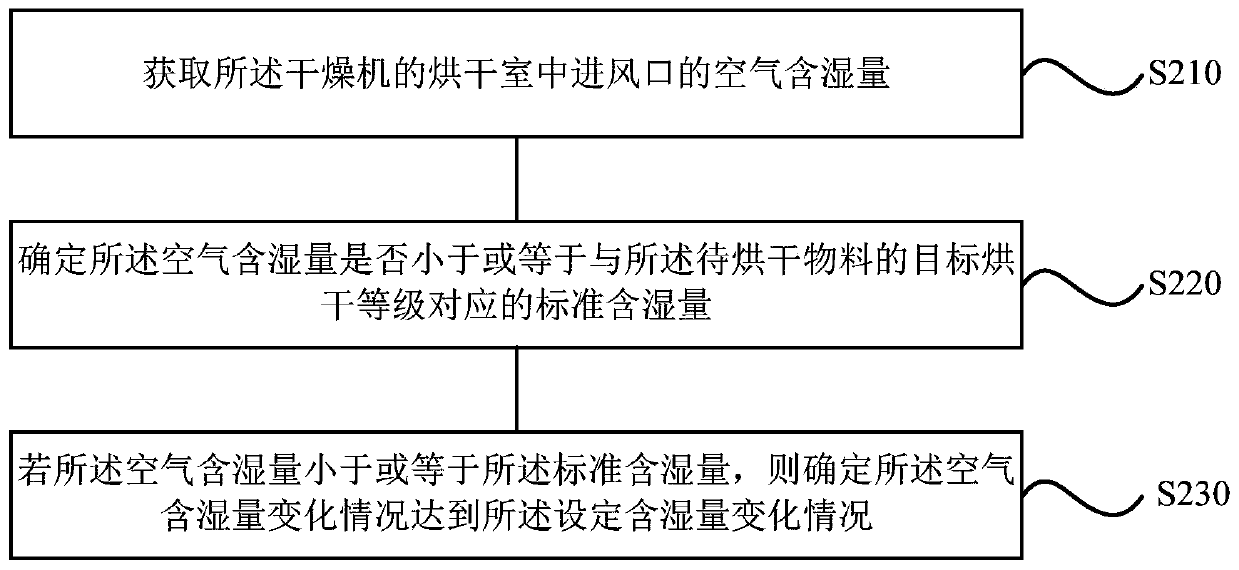

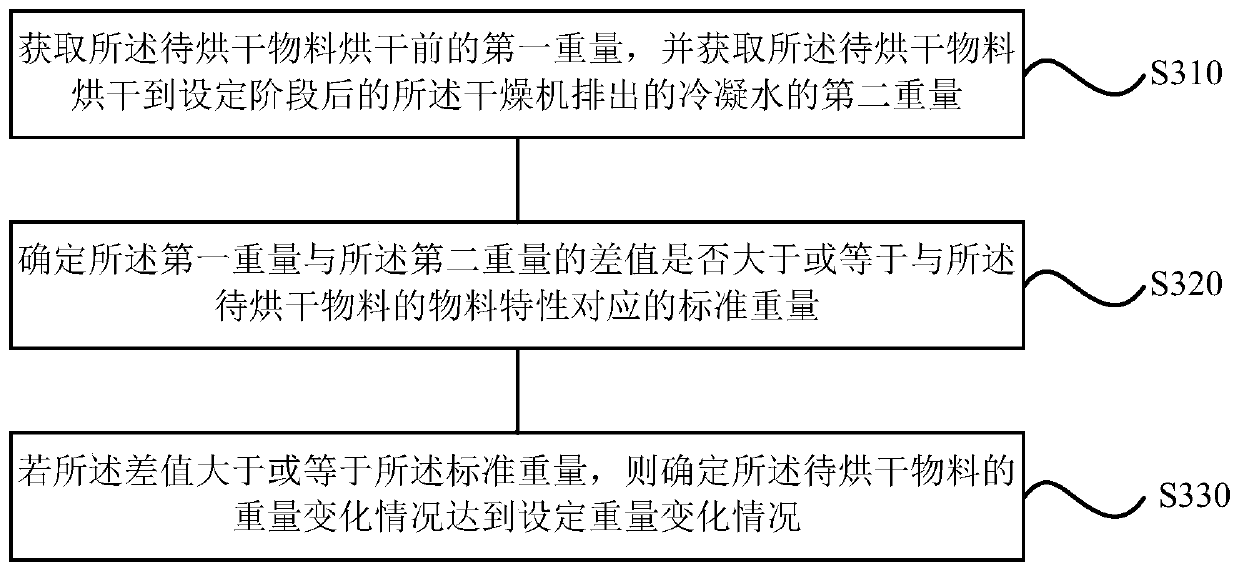

Control method and device of drying machine and drying machine

ActiveCN108679999AHigh degree of automation controlSolve the problem that the drying degree cannot be accurately controlledDrying solid materialsWeight changePulp and paper industry

The invention discloses a control method and device of a drying machine and the drying machine. The method comprises the following steps that whether the moisture content change condition of air at anair inlet in a drying chamber of the drying machine reaches a set moisture content change condition or not is determined, and / or whether the weight change condition of a to-be-dried material reachesa set weight change condition or not is determined; and if the moisture content change condition of the air reaches the set moisture content change condition, and / or if the weight change condition ofthe to-be-dried material reaches the set weight change condition, the drying machine is shut down. According to the scheme, the defects that in the prior art, the manual labor amount is large, the drying effect is poor and the quality of the material cannot be guaranteed can be overcome, and the beneficial effects that the manual labor amount is small, the drying effect is good and the quality ofthe material can be guaranteed can be achieved.

Owner:GREE ELECTRIC APPLIANCES INC

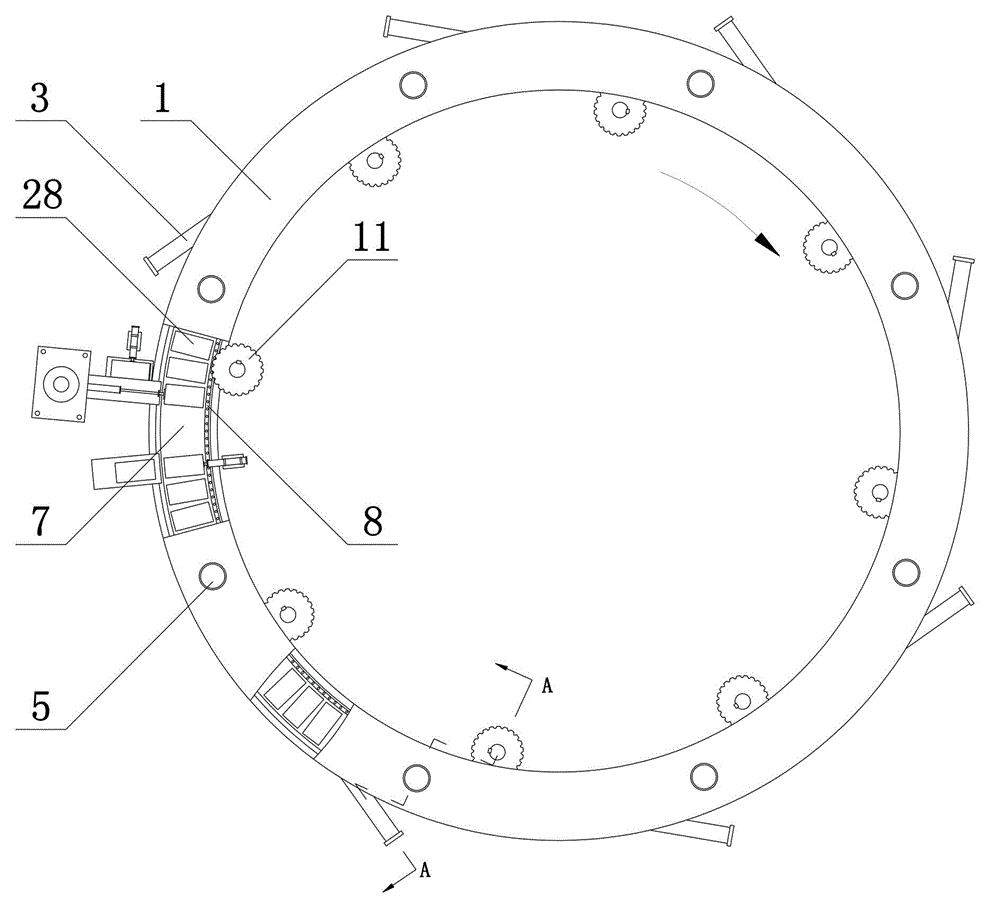

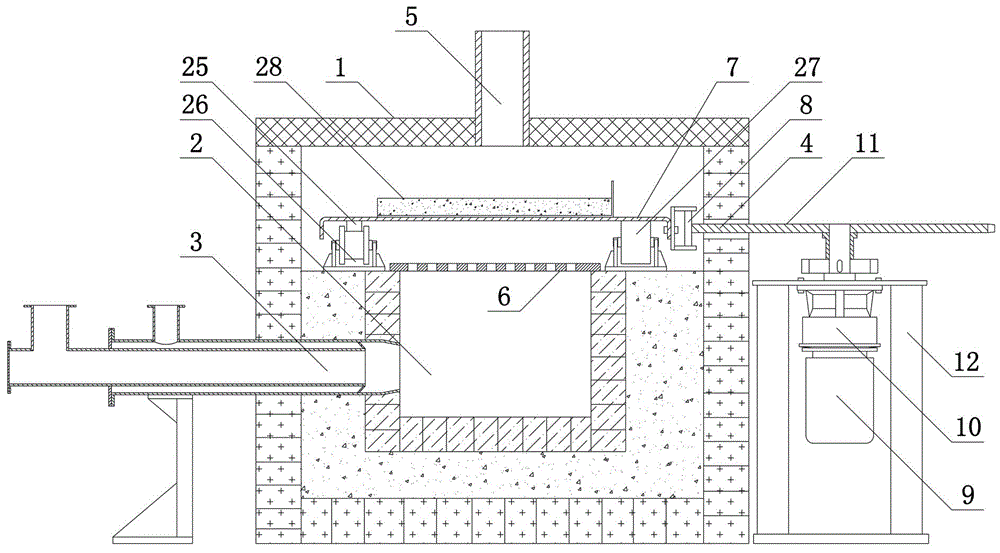

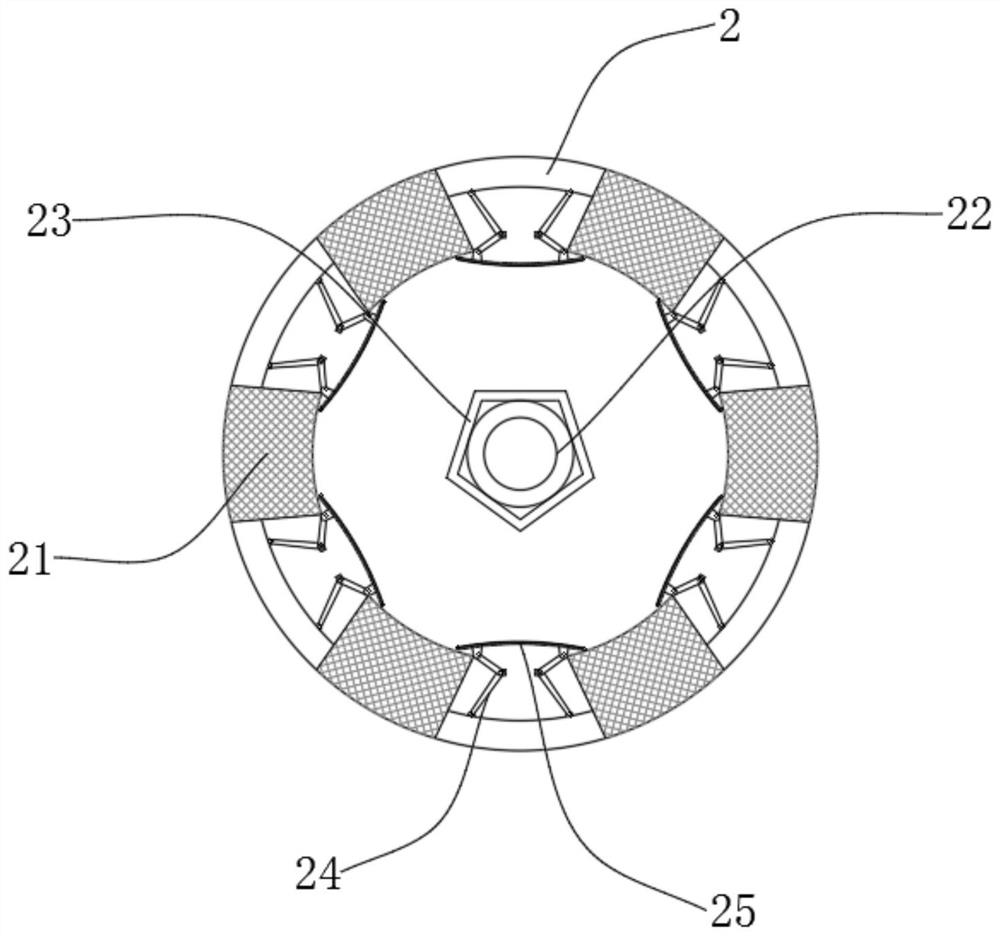

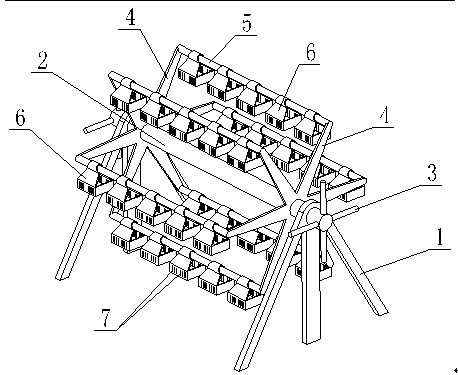

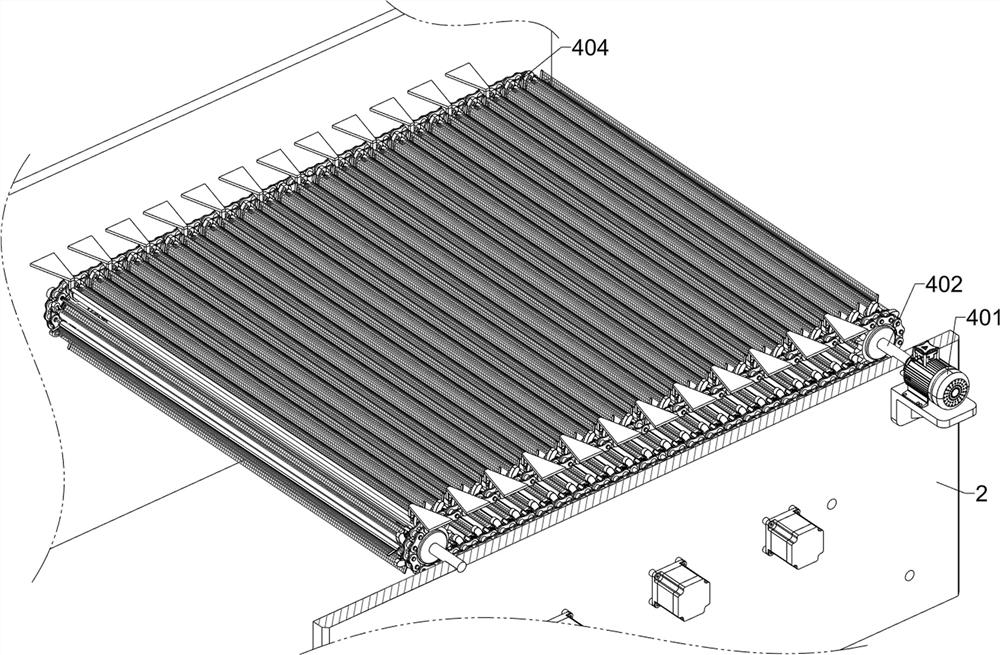

Annular gas drying complete equipment

ActiveCN102980382ASmall footprintDesign scienceDrying machines with progressive movementsDrying solid materialsSmall footprintEngineering

The invention provides annular gas drying complete equipment which comprises an annular heat preservation kiln and an annular material conveying device, wherein the annular heat preservation kiln comprises an annular kiln body, an annular flame path which is built in the annular kiln body and M flame nozzles; the annular material conveying device comprises an annular material conveying platform, a plurality of groups of platform supporting rollers, an annular chain and N groups of power plants, wherein the platform supporting rollers are arranged in an annular shape, the annular chain is installed on the annular material conveying platform, and the N groups of power plants are arranged on one side of the annular chain; the annular material conveying platform, the platform supporting rollers and the annular chain are arranged in the annular kiln body; the platform supporting rollers are installed on the upper end surface of the annular flame path; the power plants are arranged outside the annular kiln body; and local wheel bodies of chain wheels of the N groups of power plants are respectively arranged in N mouths of the chain wheels. The annular gas drying complete equipment has the advantages of scientific design, less occupied area, good drying effect, convenience in production supervision and control and stability in operation.

Owner:信阳市四通机械制造有限公司

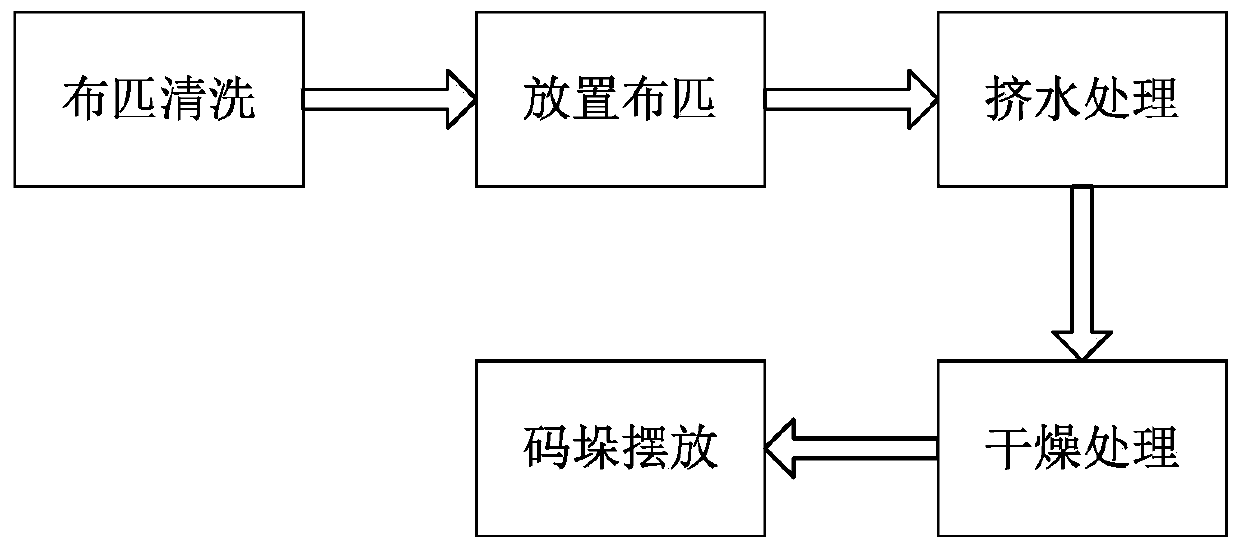

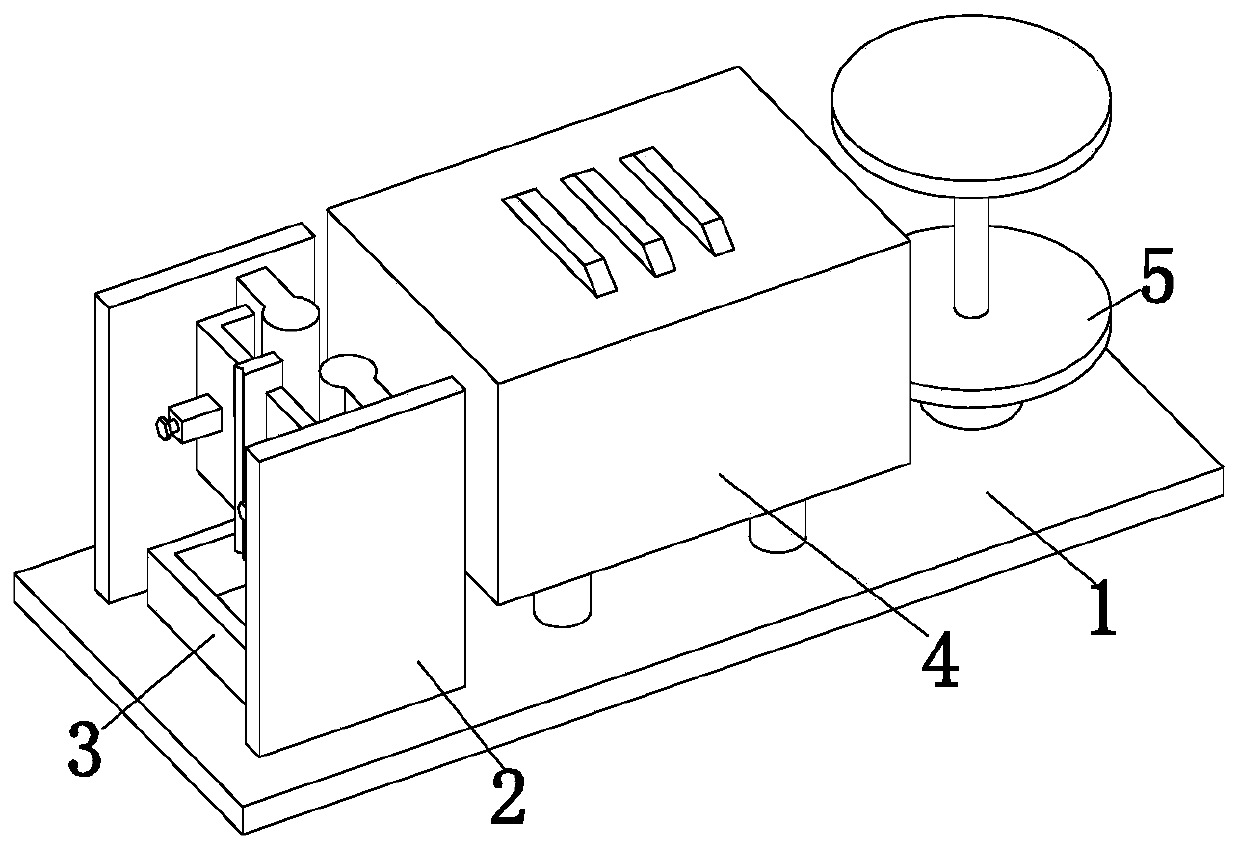

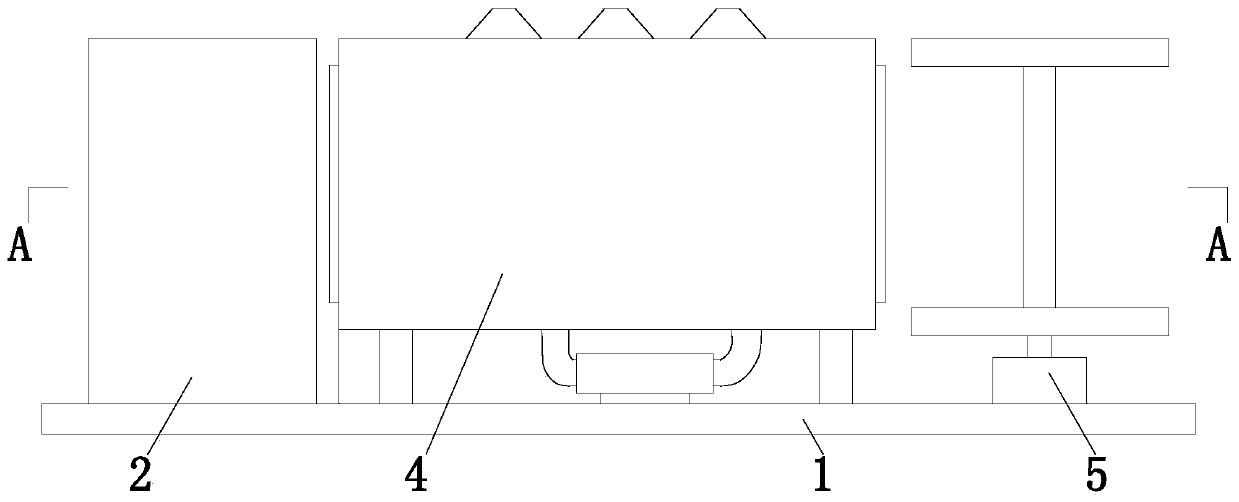

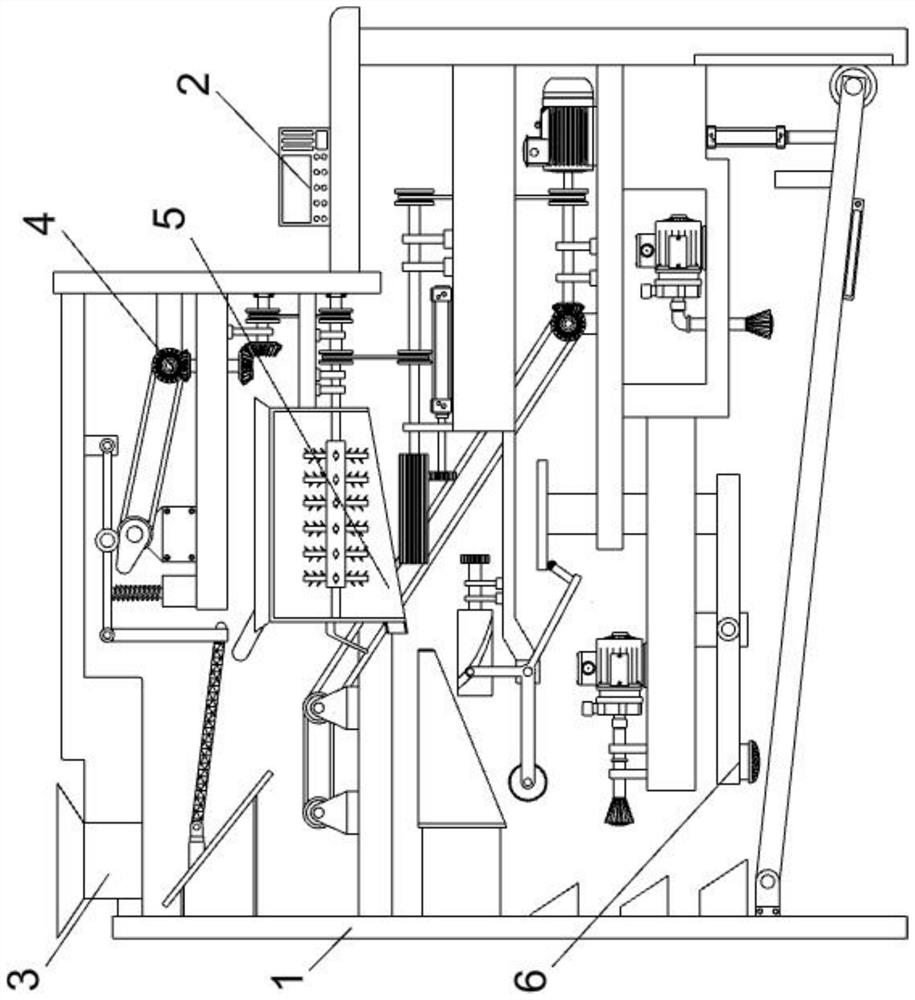

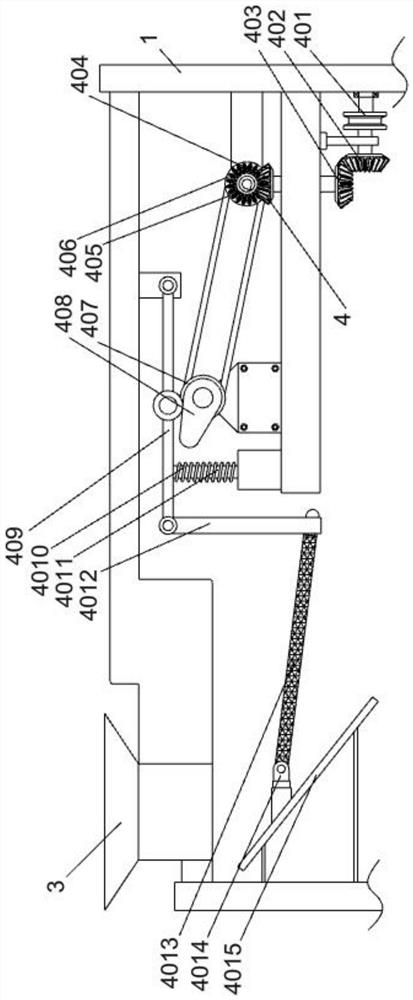

Textile cloth after-treatment process

InactiveCN111350042AReduce drying efficiencyReduced aestheticsDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

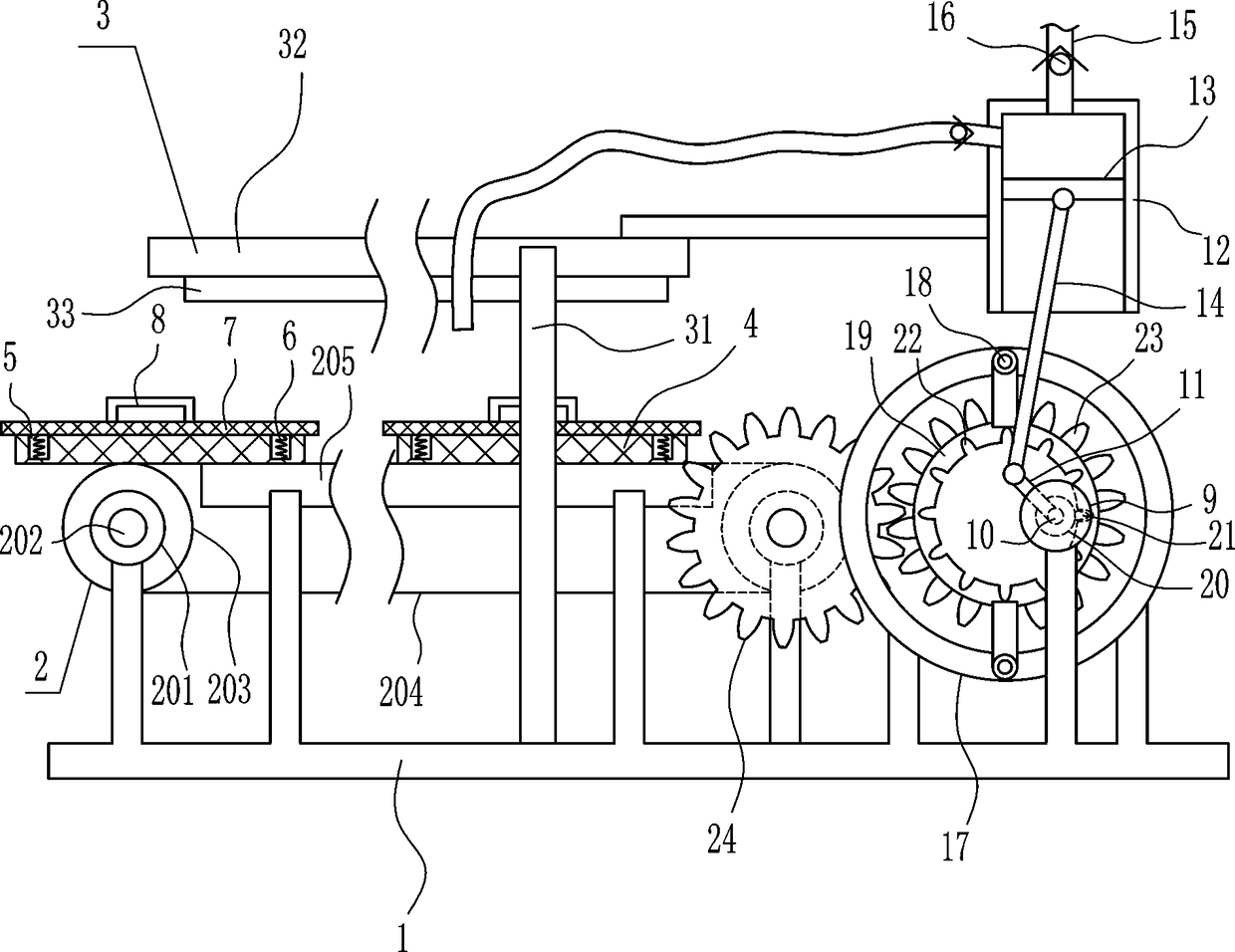

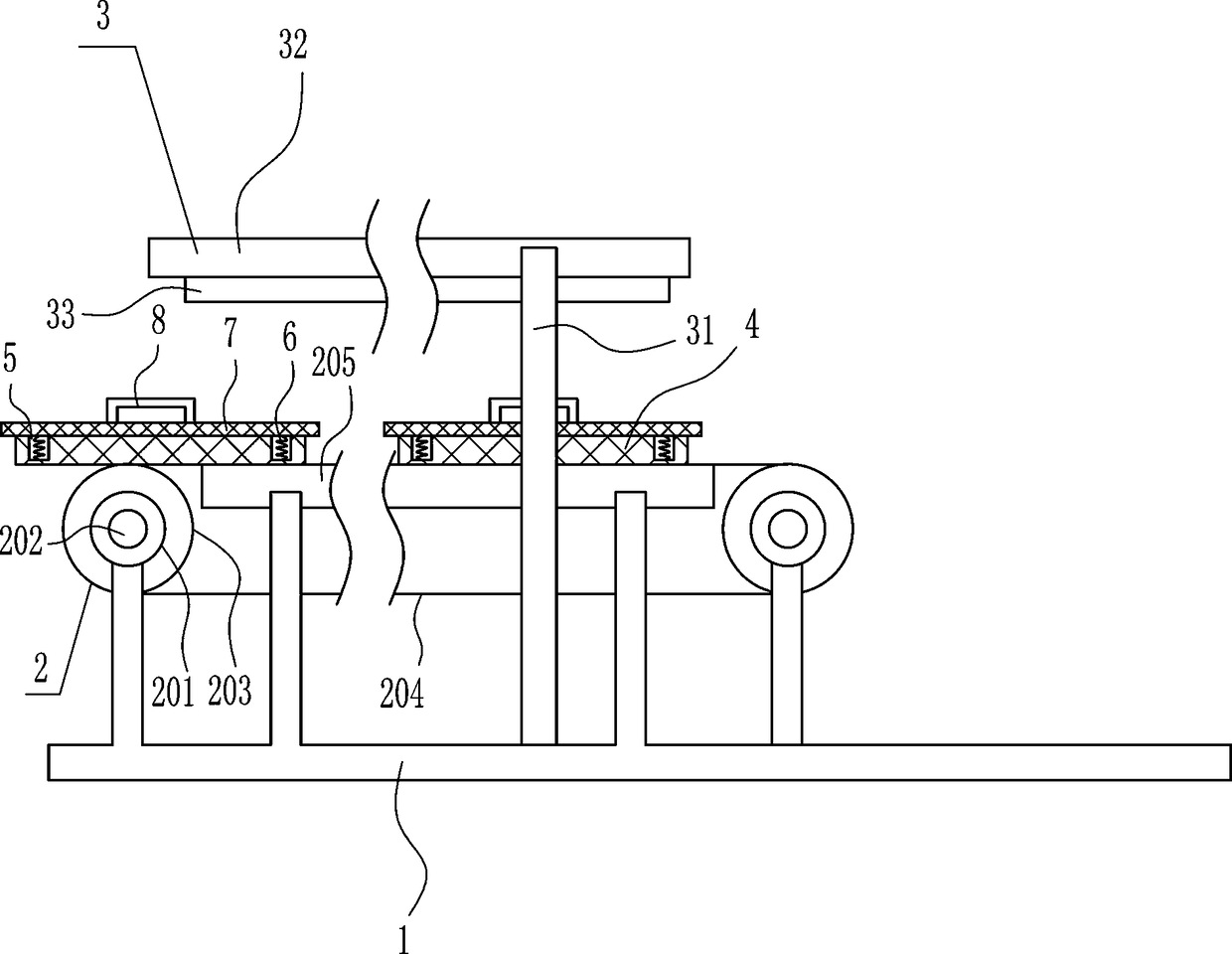

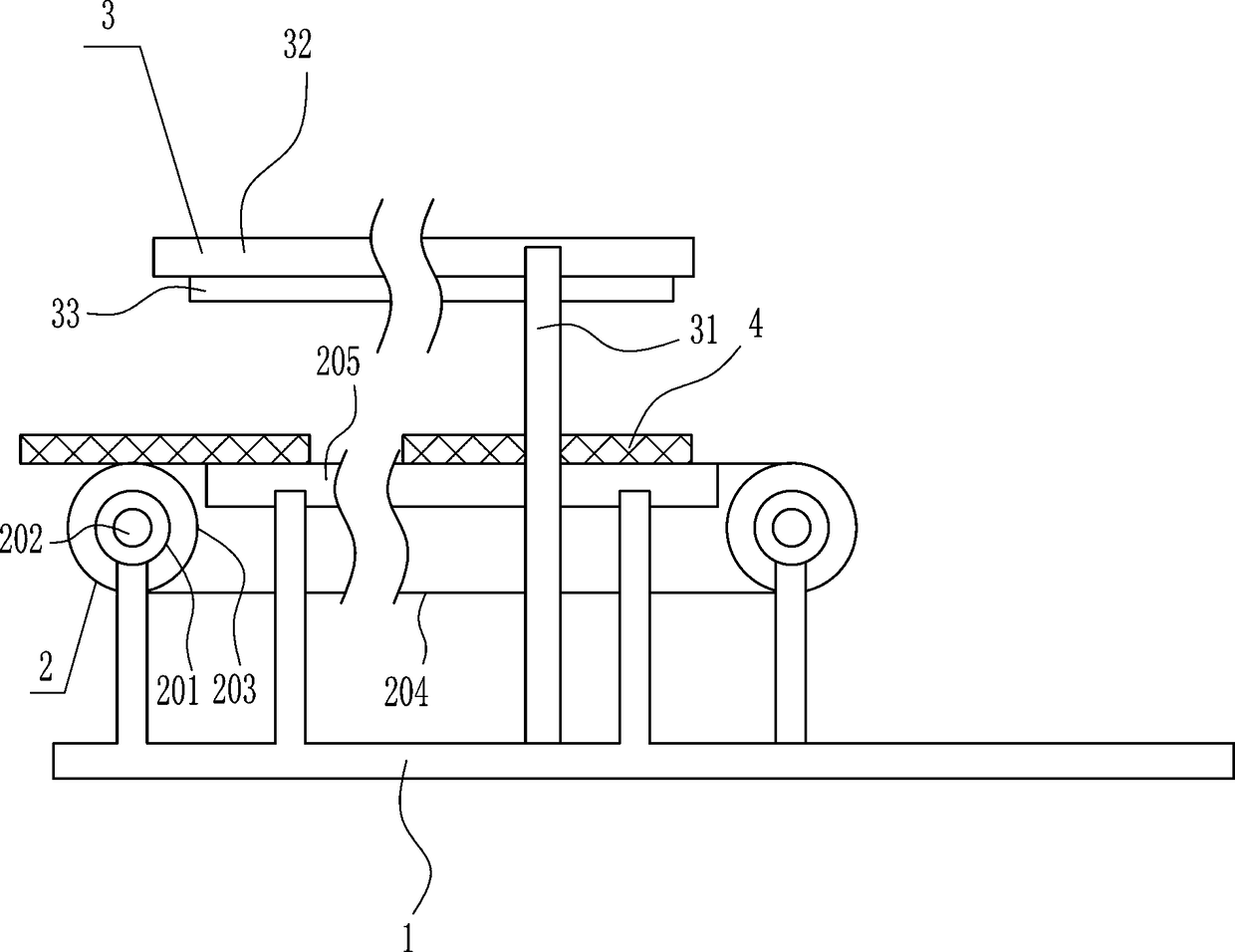

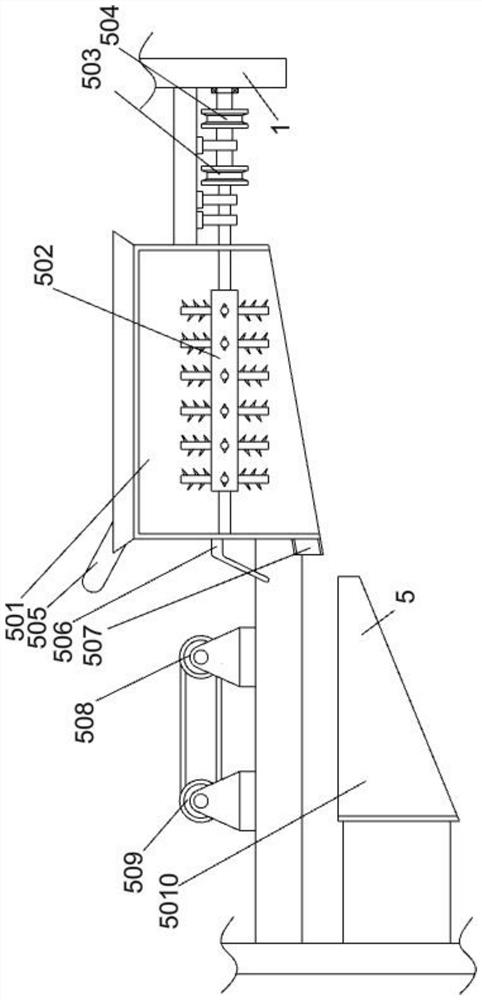

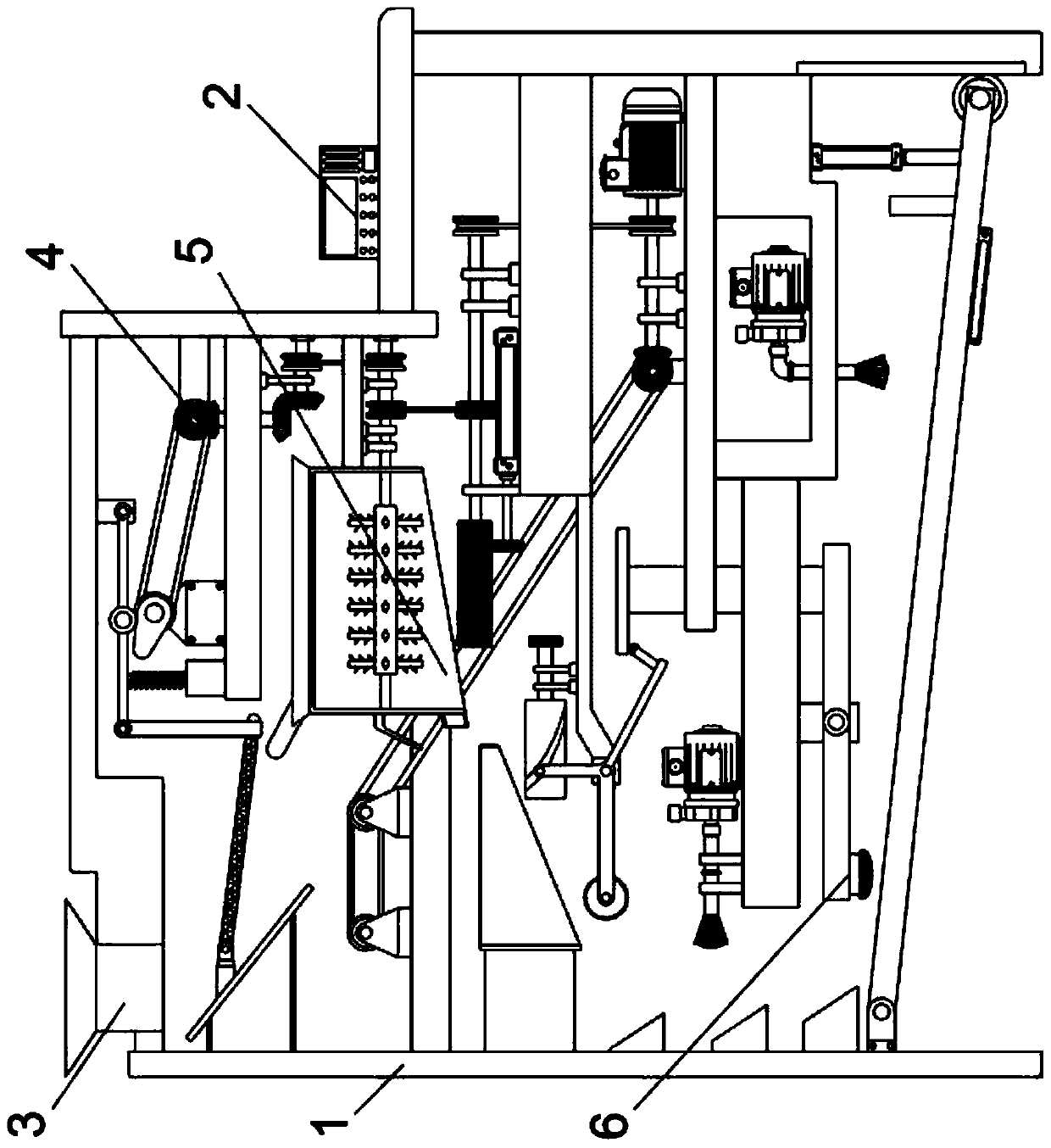

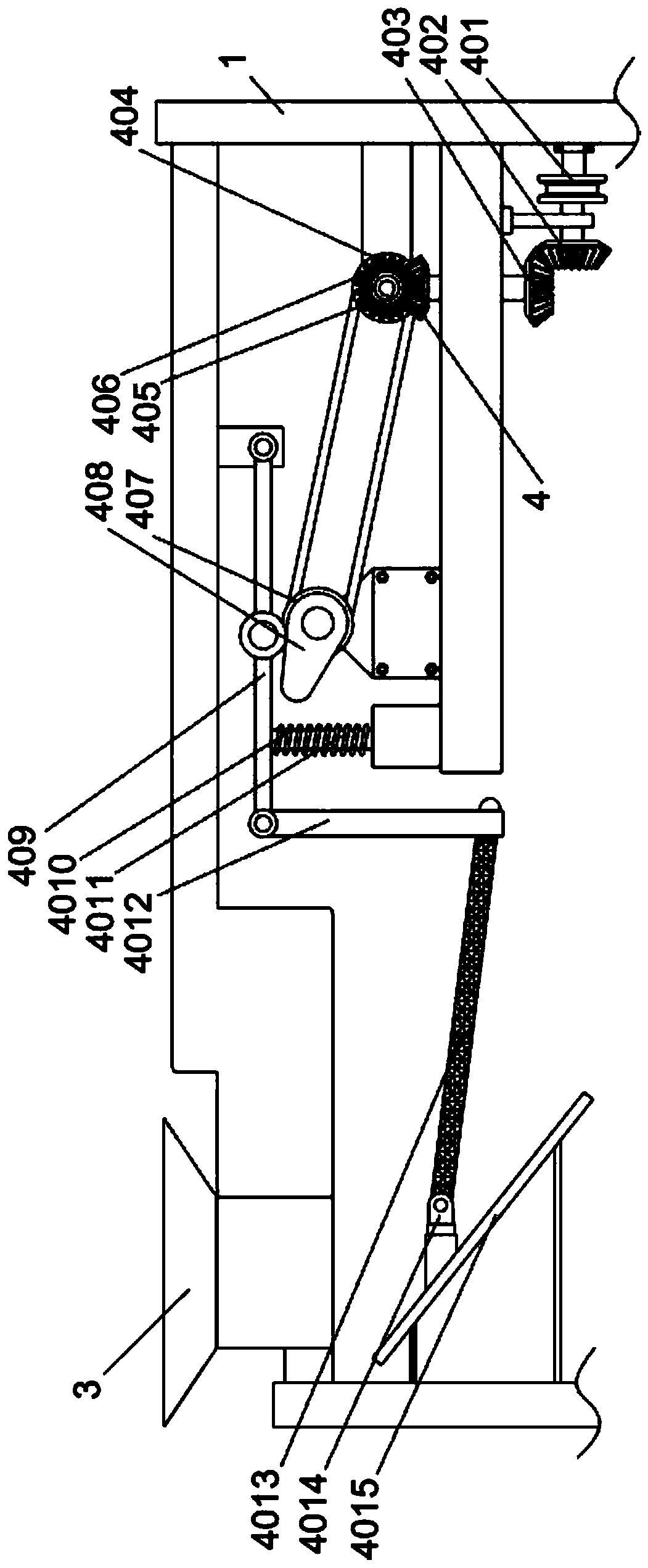

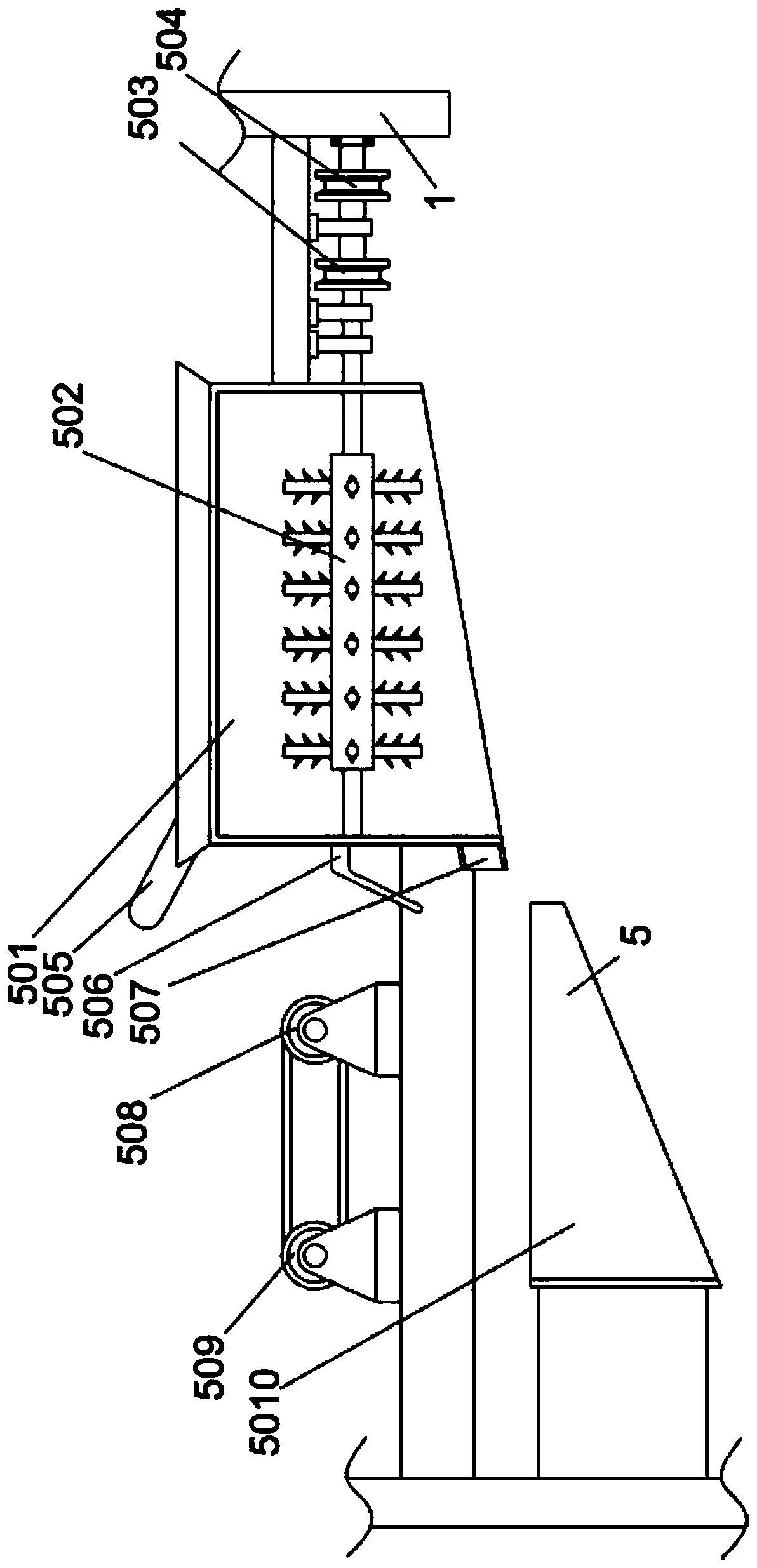

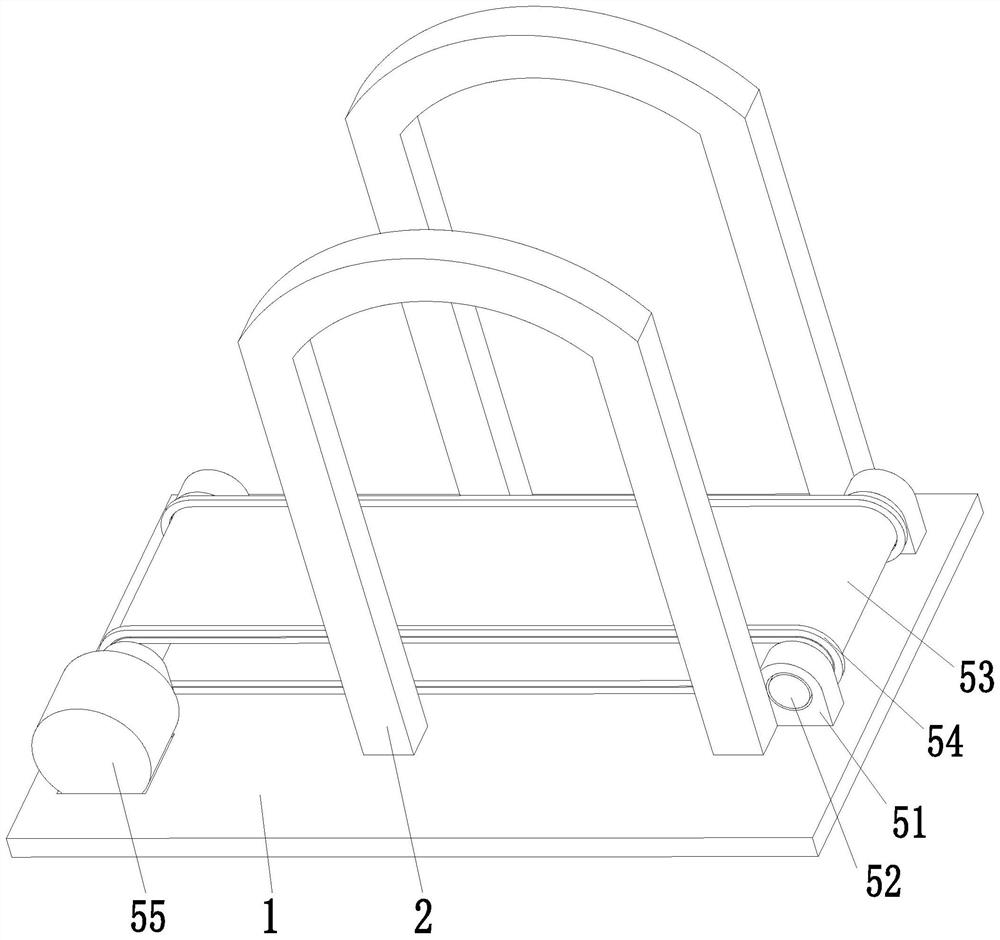

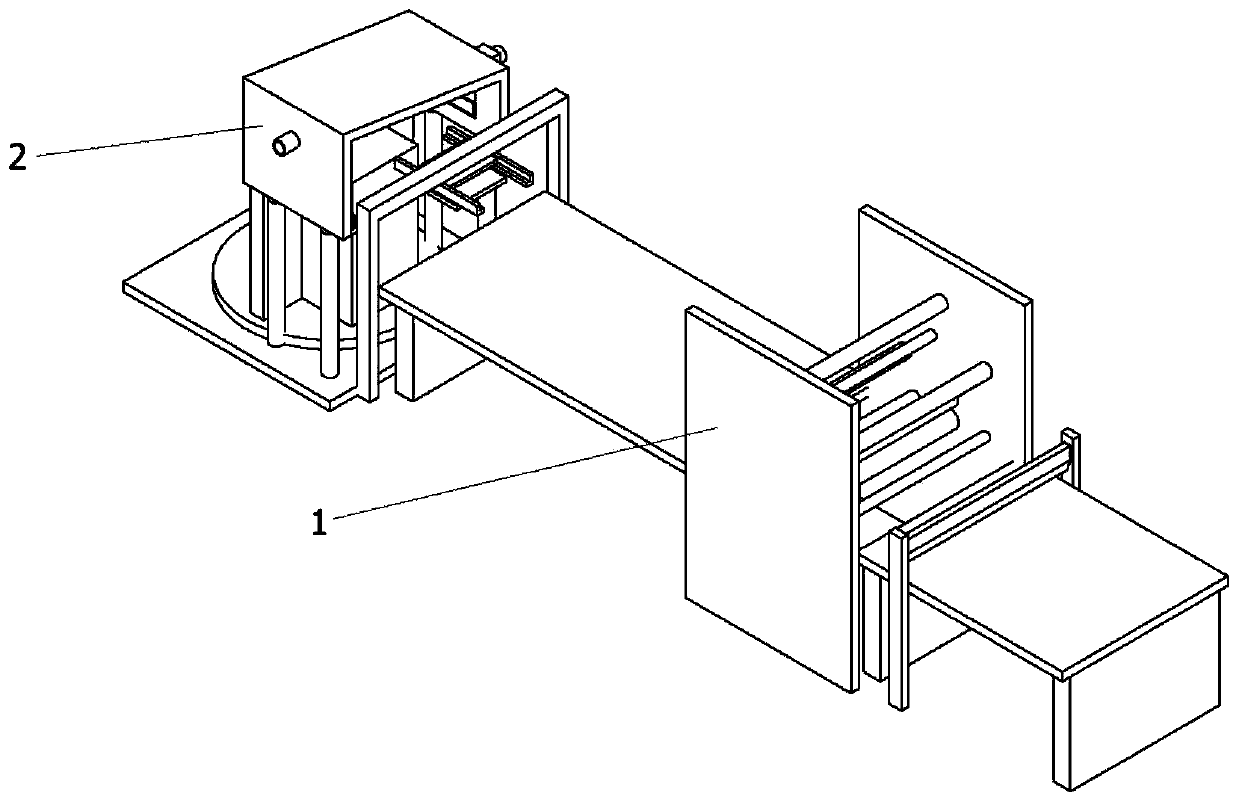

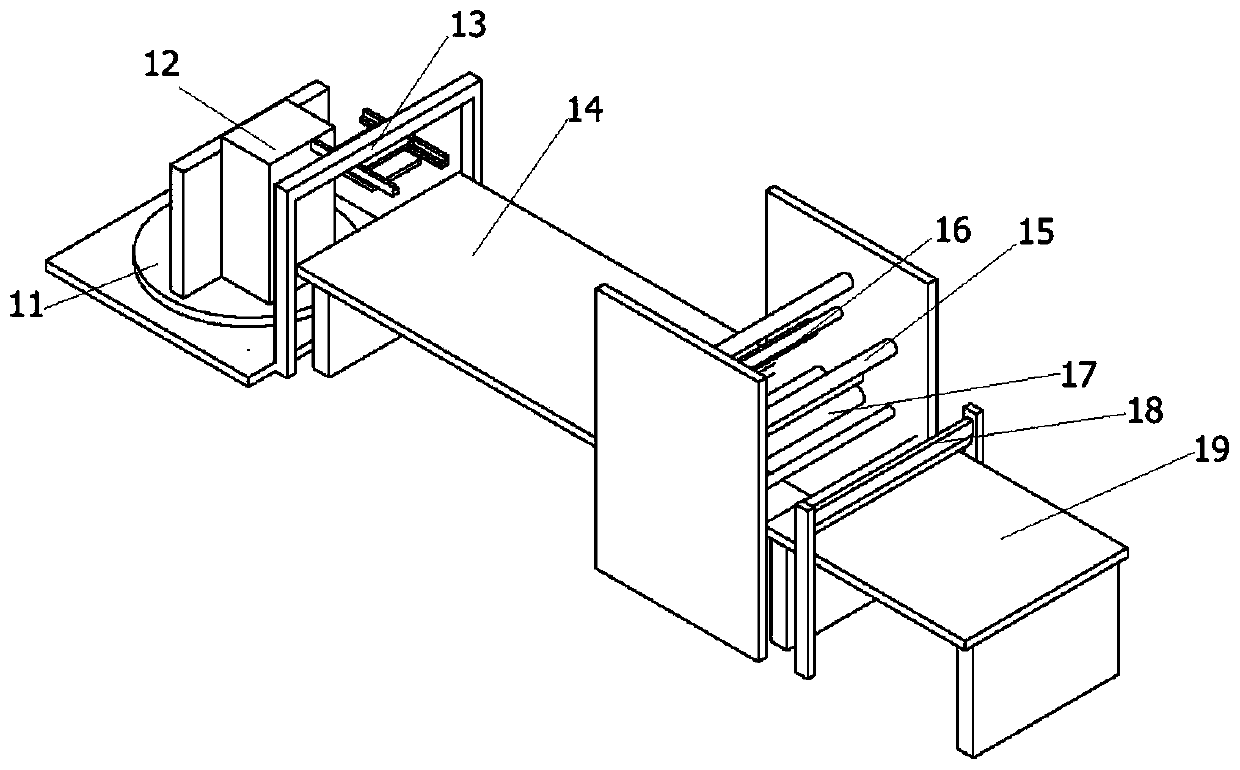

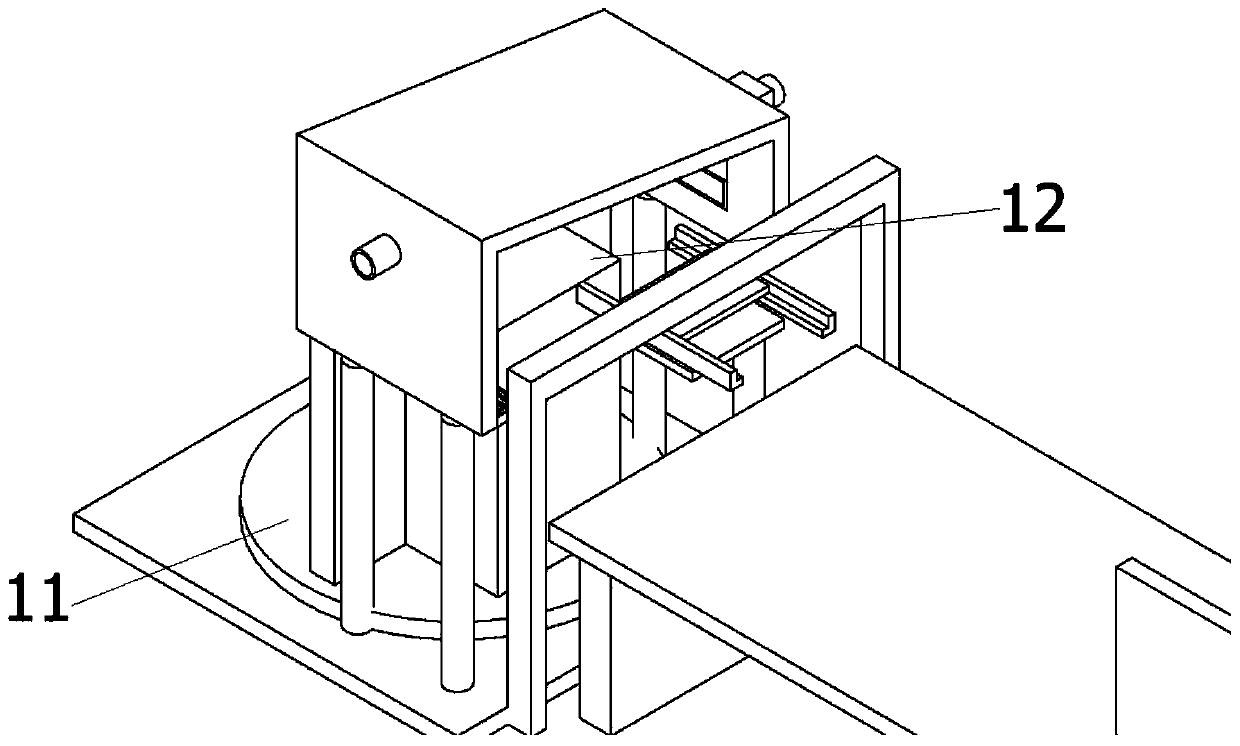

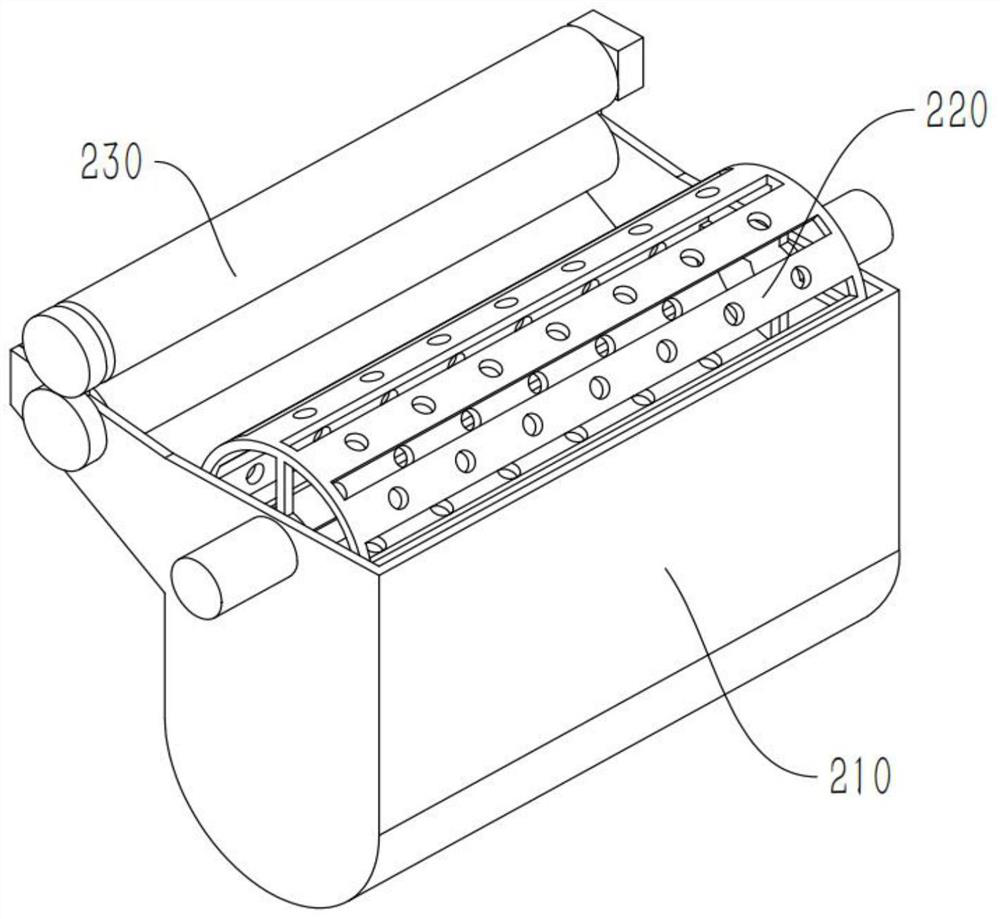

The invention relates to a textile cloth after-treatment process. The textile cloth after-treatment process comprises a bottom plate, a water squeezing device, a water collecting tank, a drying deviceand a traction device; the water squeezing device is installed at the upper end of the bottom plate; the water collecting groove is arranged below the water squeezing device; the water collecting groove is installed on the bottom plate; the drying device is arranged at the right side of the water collecting groove; the drying device is installed on the bottom plate; and the traction device is arranged at the right side of the drying device and the traction device is installed on the bottom plate. The textile cloth after-treatment process provided by the invention solves the problems that whenexisting equipment is used for drying the textile cloth, the cloth is directionally dried, hot air is easy to dissipate around, thus the efficiency of drying the cloth by the hot air is reduced, in addition, the drying time of the cloth cannot be increased in a limited space, thereby reducing the drying efficiency; and meanwhile, the cloth cannot be scraped while the cloth is dried, the cloth isprone to wrinkles after being dried, which reduces the attractiveness of the cloth after being dried and reduces the drying effect.

Owner:倪邦强

Biological sample movable drying equipment

InactiveCN108151504AFully receivedEasy to take outDrying gas arrangementsDrying chambers/containersPulp and paper industryBreathing

The invention relates to drying equipment, in particular to biological sample movable drying equipment, and aims at providing the biological sample movable drying equipment through which heat of a drying lamp and hot air can be sufficiently combined for drying, and samples are conveniently taken out. To achieve the above technical purpose, the biological sample movable drying equipment is providedand comprises a base and the like. The base is connected with a moving mechanism and a drying mechanism, the drying mechanism is located above the moving mechanism. Containing ventilation plates areevenly placed on the moving mechanism. By means of the biological sample movable drying equipment, the effect that heat of the drying lamp and hot air for drying can be sufficiently combined for drying, and the samples are conveniently taken out is achieved; and through the arrangement of the moving mechanism and the drying mechanism, the biological samples can be dried while moved, and workers can conveniently take out the dried samples.

Owner:李建云

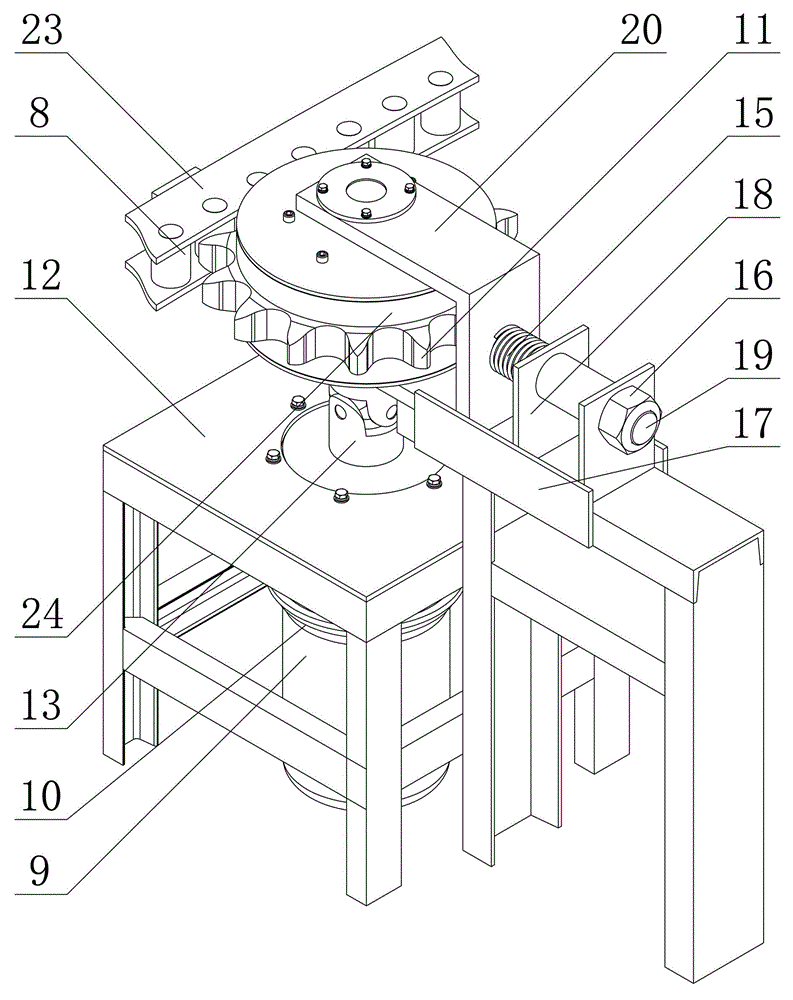

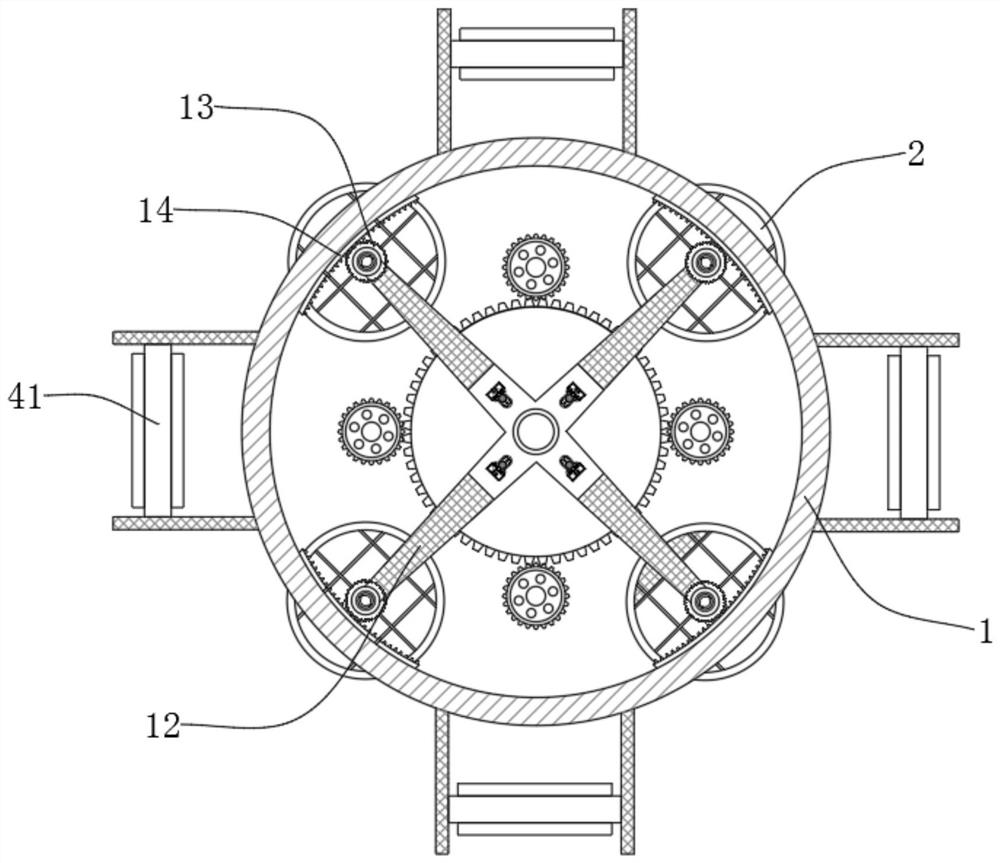

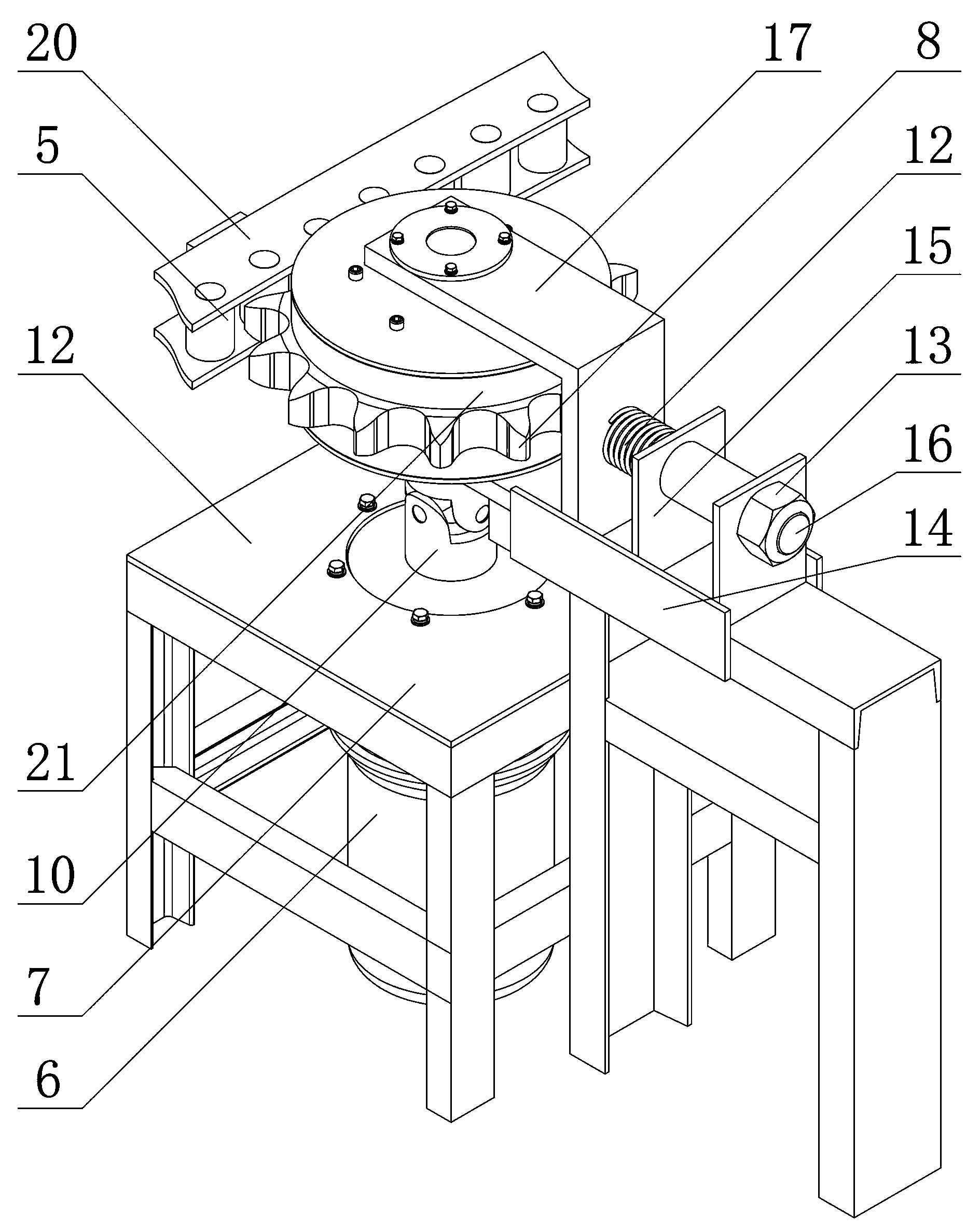

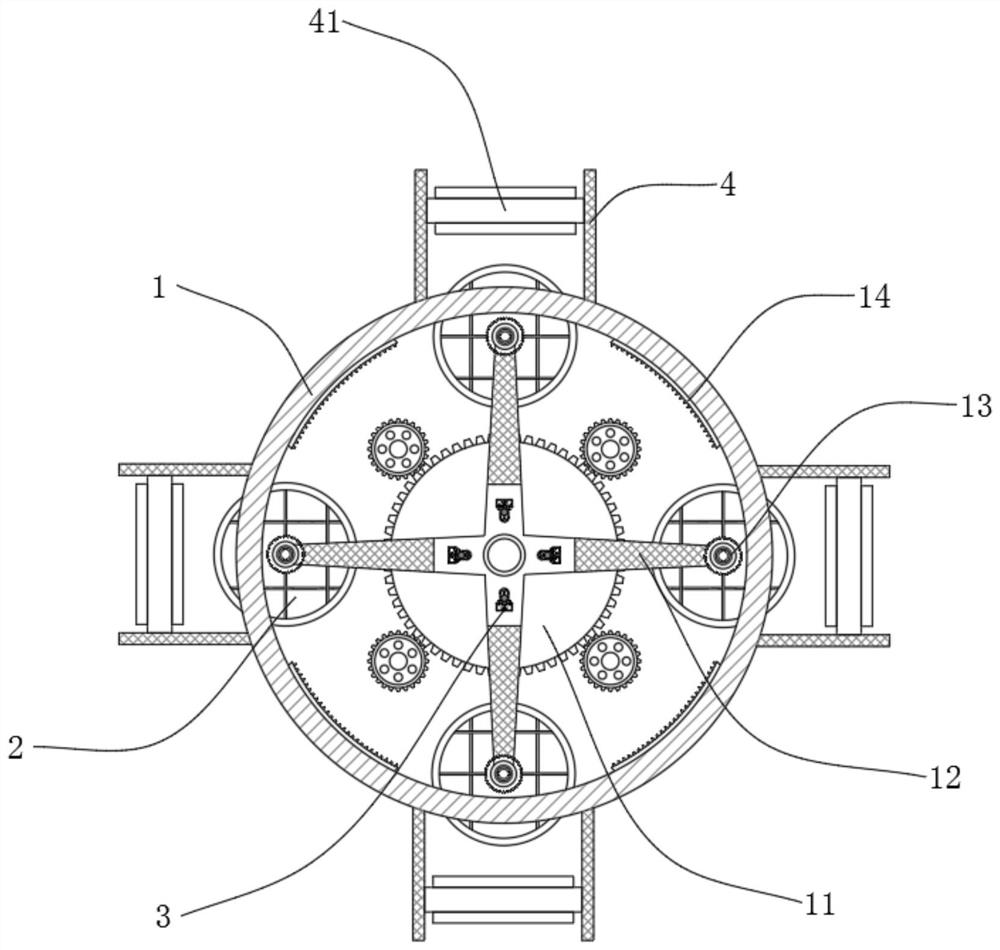

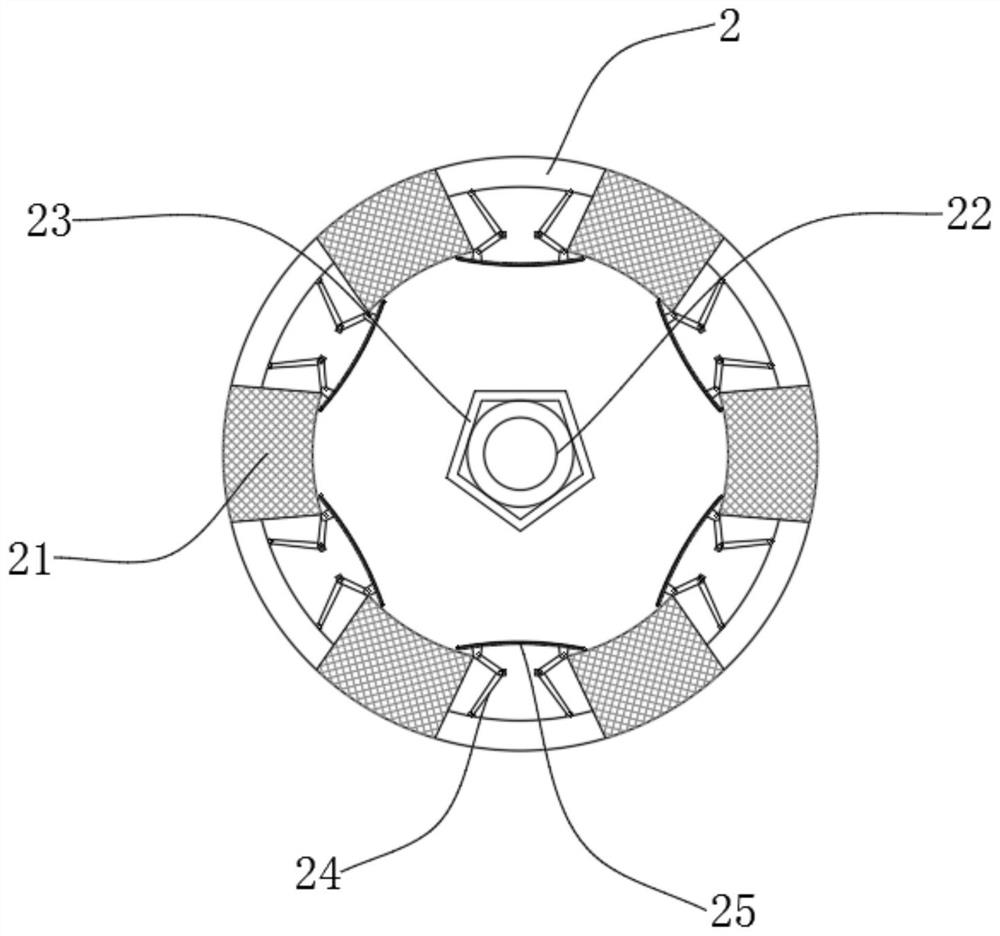

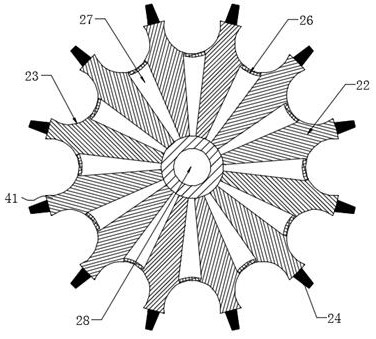

Raw material centrifugal impurity removal device capable of adjusting wind speed for edible oil processing

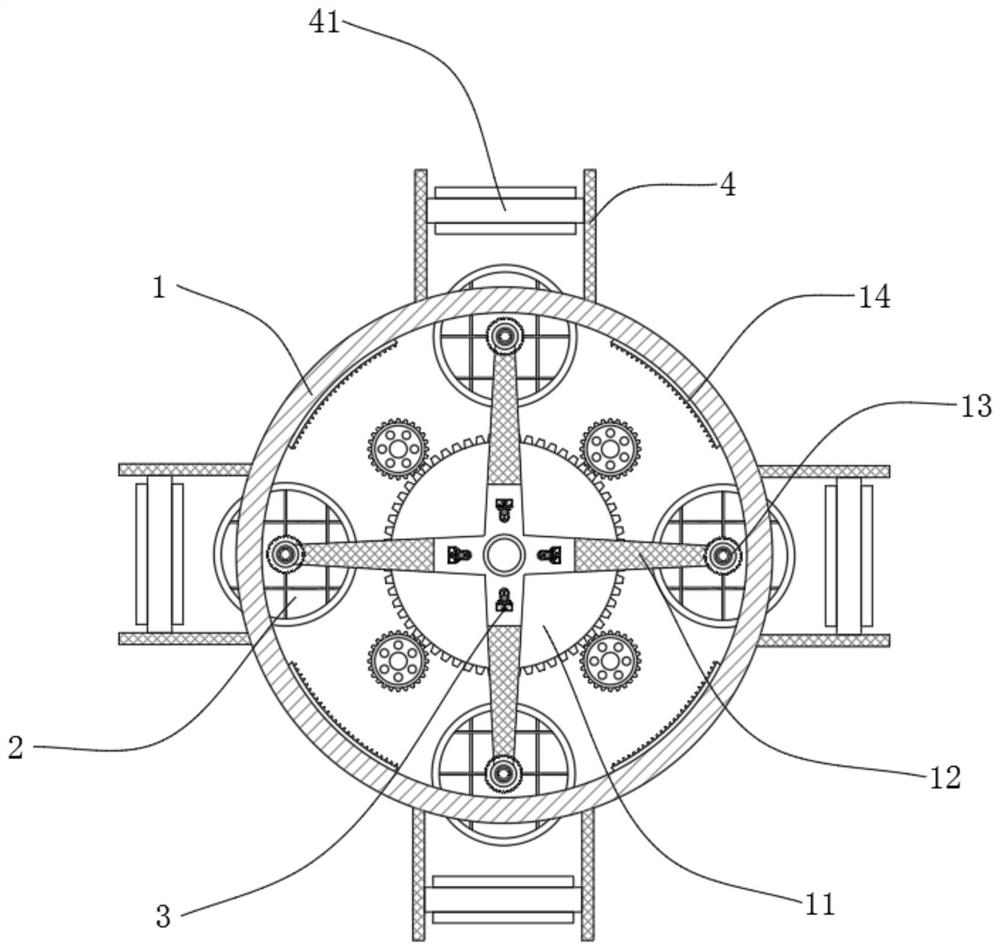

ActiveCN113000354AImprove the effect of impurity removalUniform and comprehensive removalSievingScreeningPhysicsEdible oil

The invention relates to the technical field of edible oil processing, and discloses a raw material centrifugal impurity removal device capable of adjusting wind speed for edible oil processing. The raw material centrifugal impurity removal device comprises a supporting ring, wherein a driving gear is rotatably connected to the center position of the inner part of the supporting ring; a swinging rod is fixedly connected to a rotating shaft of the driving gear; a transmission gear is rotatably connected to one end of the swinging rod; an arc-shaped rack is fixedly connected to the inner side wall of the supporting ring; and a cleaning cylinder is fixedly connected to an output shaft of the transmission gear. The transmission gear is driven by the arc-shaped rack to rotate, so that the transmission gear drives the cleaning cylinder to rotate, the angle of the cleaning cylinder is changed, and water vapor and impurities in the cleaning cylinder can be uniformly and comprehensively removed by a drying machine; and besides, an elastic baffle plate and a baffle plate are also arranged in the cleaning cylinder, and when the cleaning cylinder rotates, raw materials are driven to shake under the action of the elastic baffle plate and the baffle plate, so that the stacked raw materials can be dispersed, and the impurity removal effect of the raw materials is further improved.

Owner:青岛天祥食品集团有限公司 +1

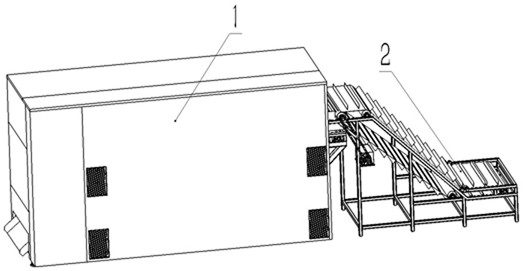

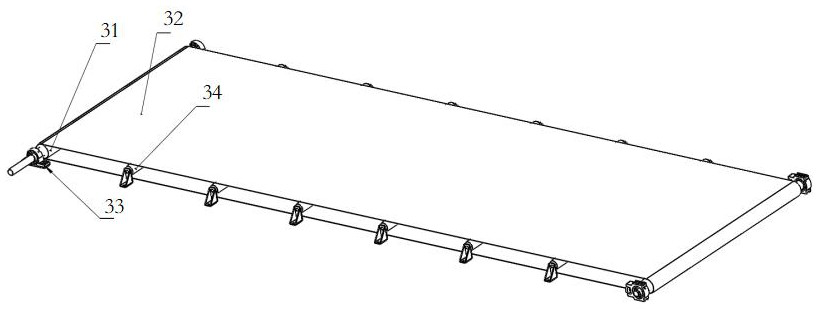

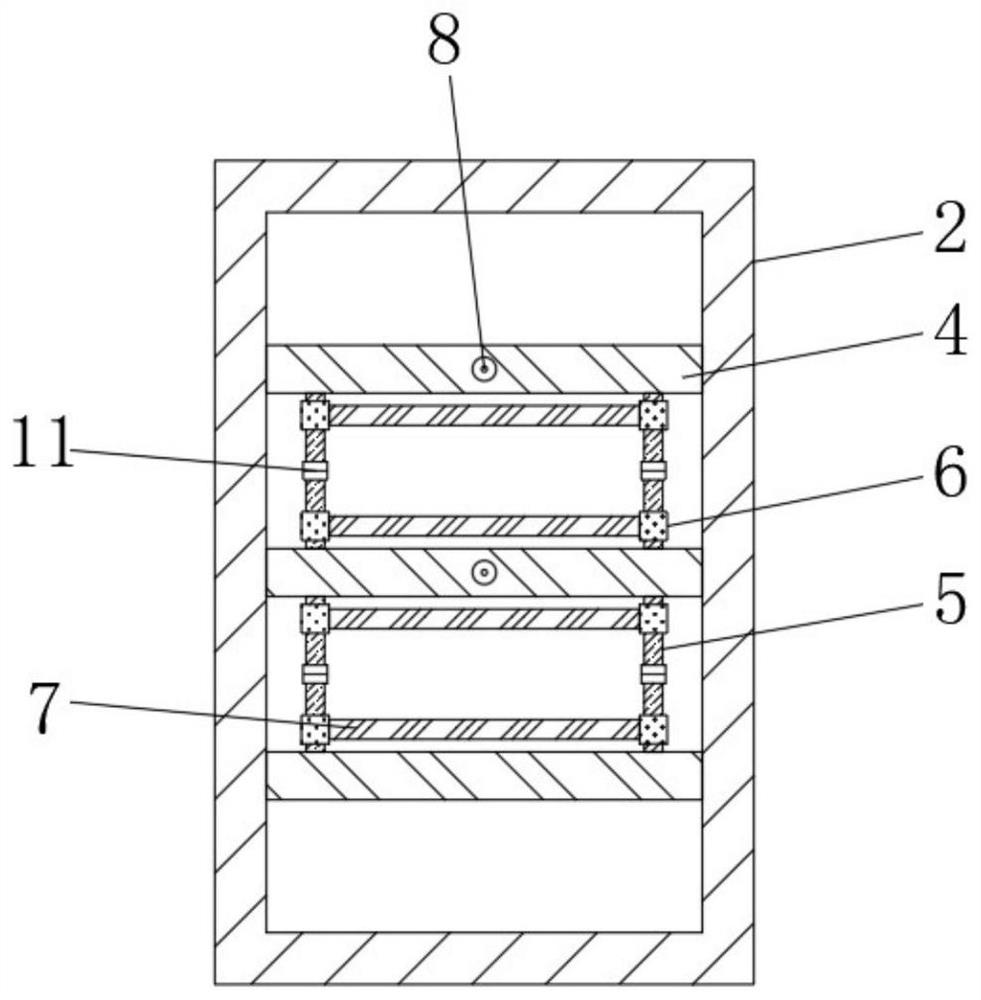

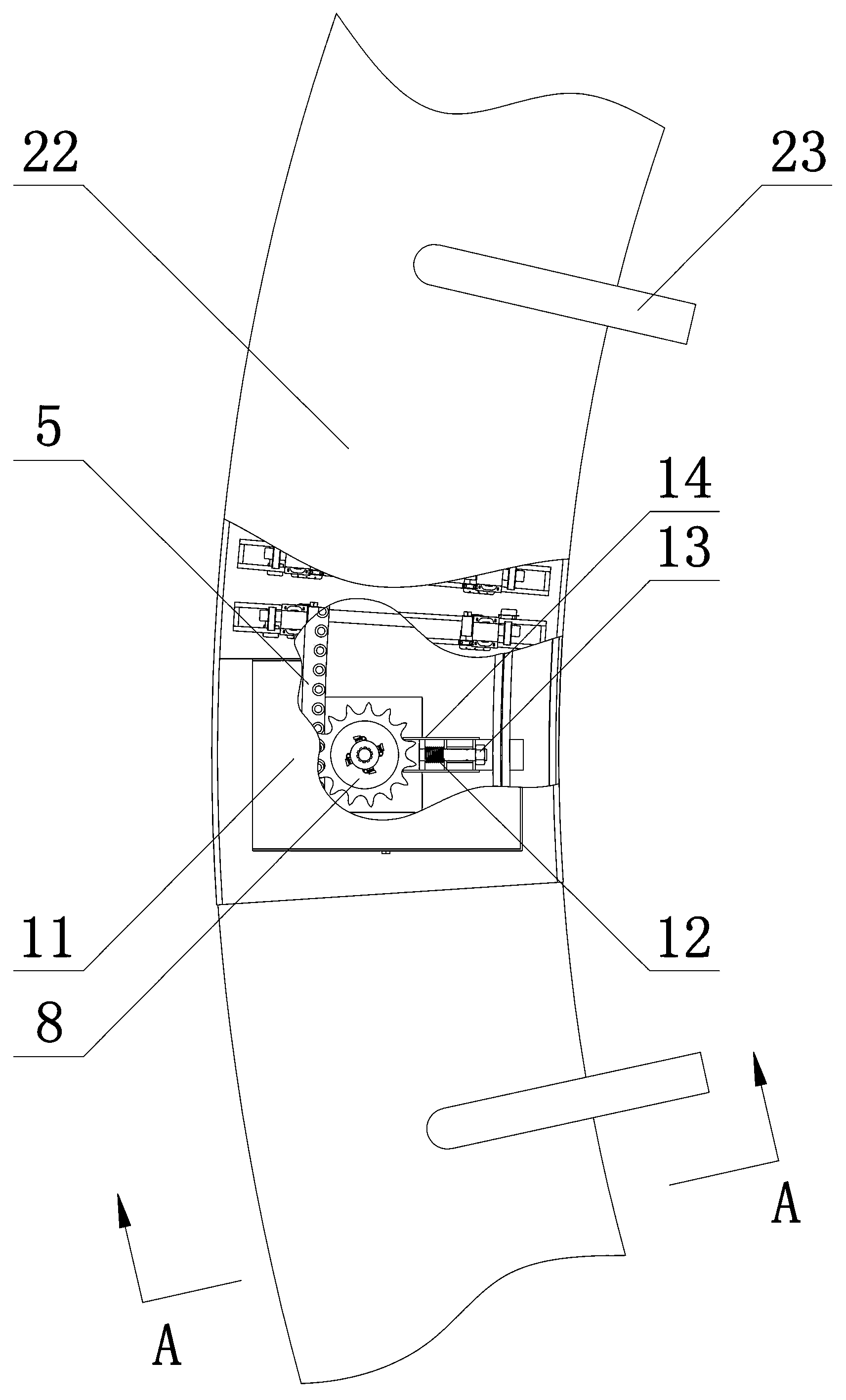

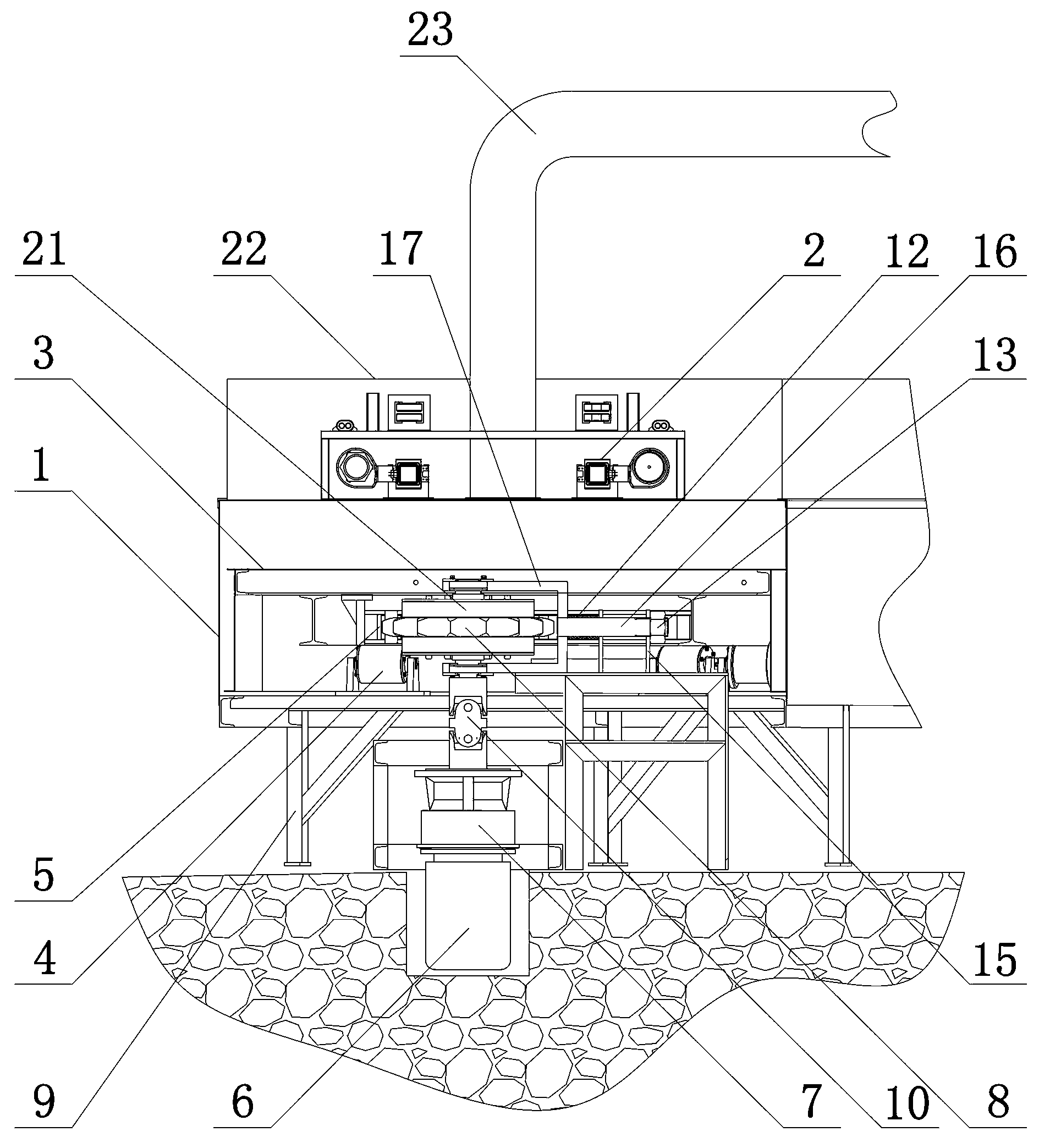

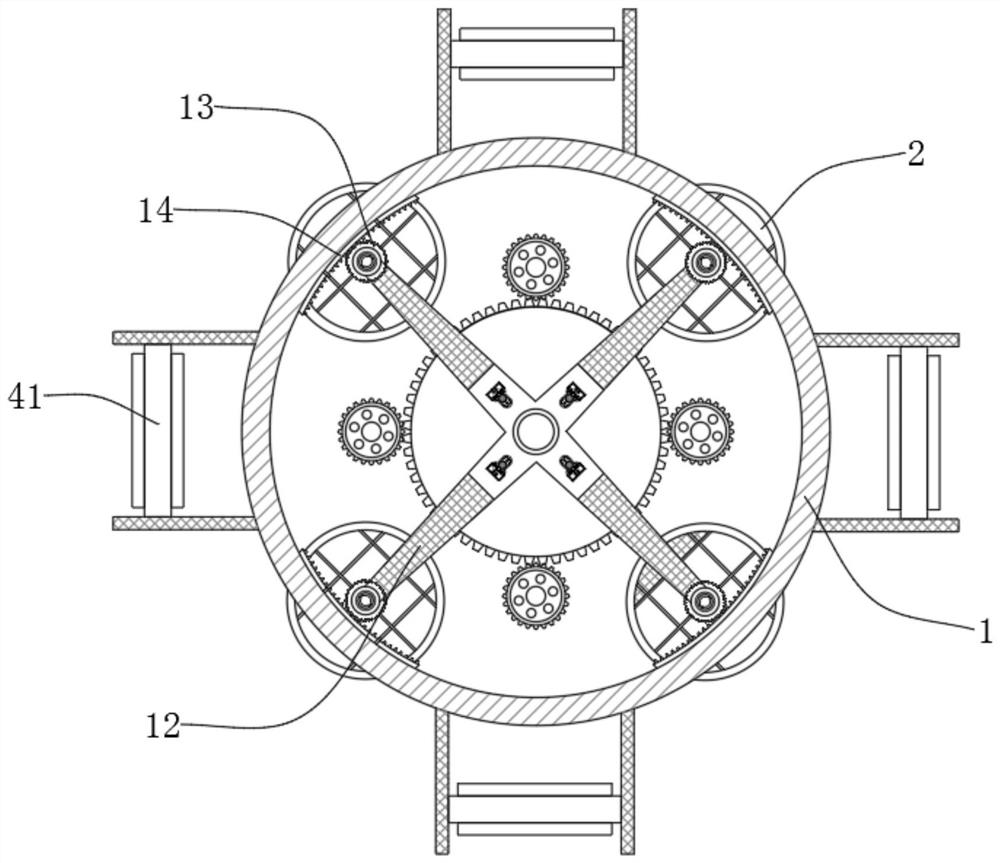

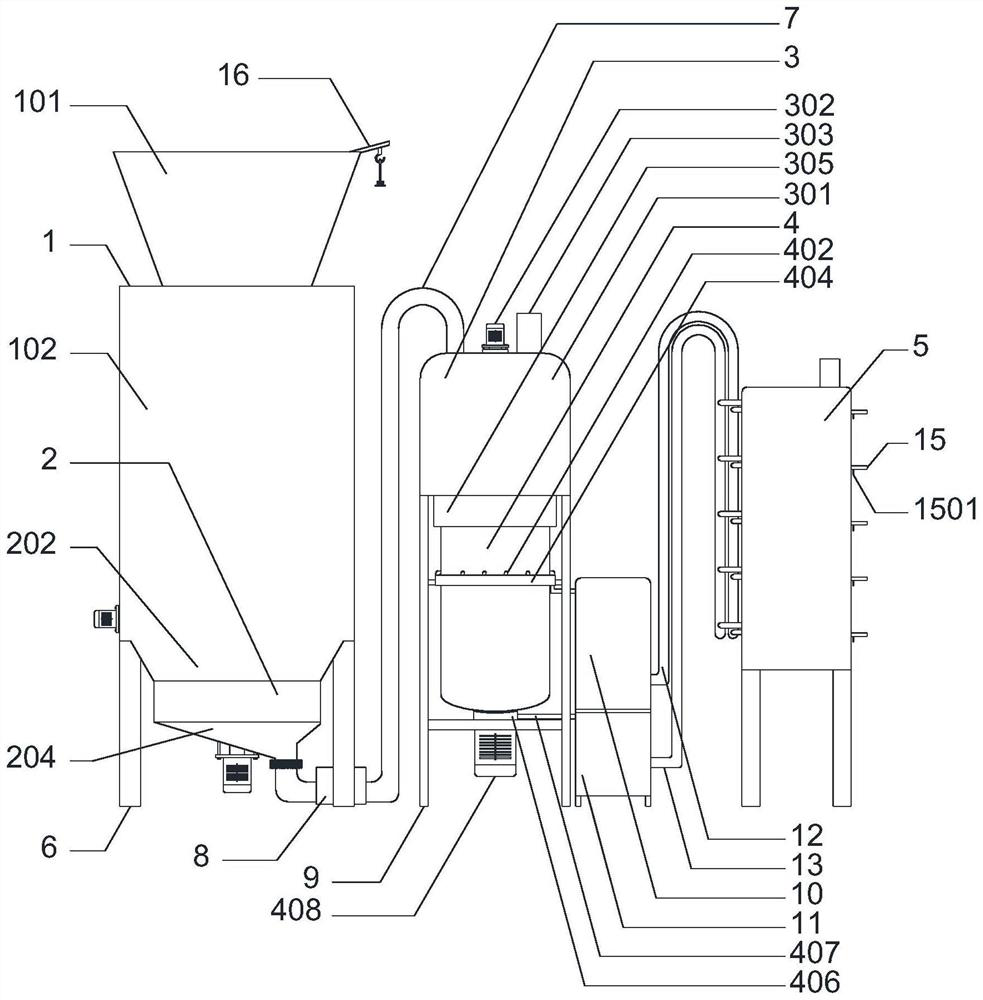

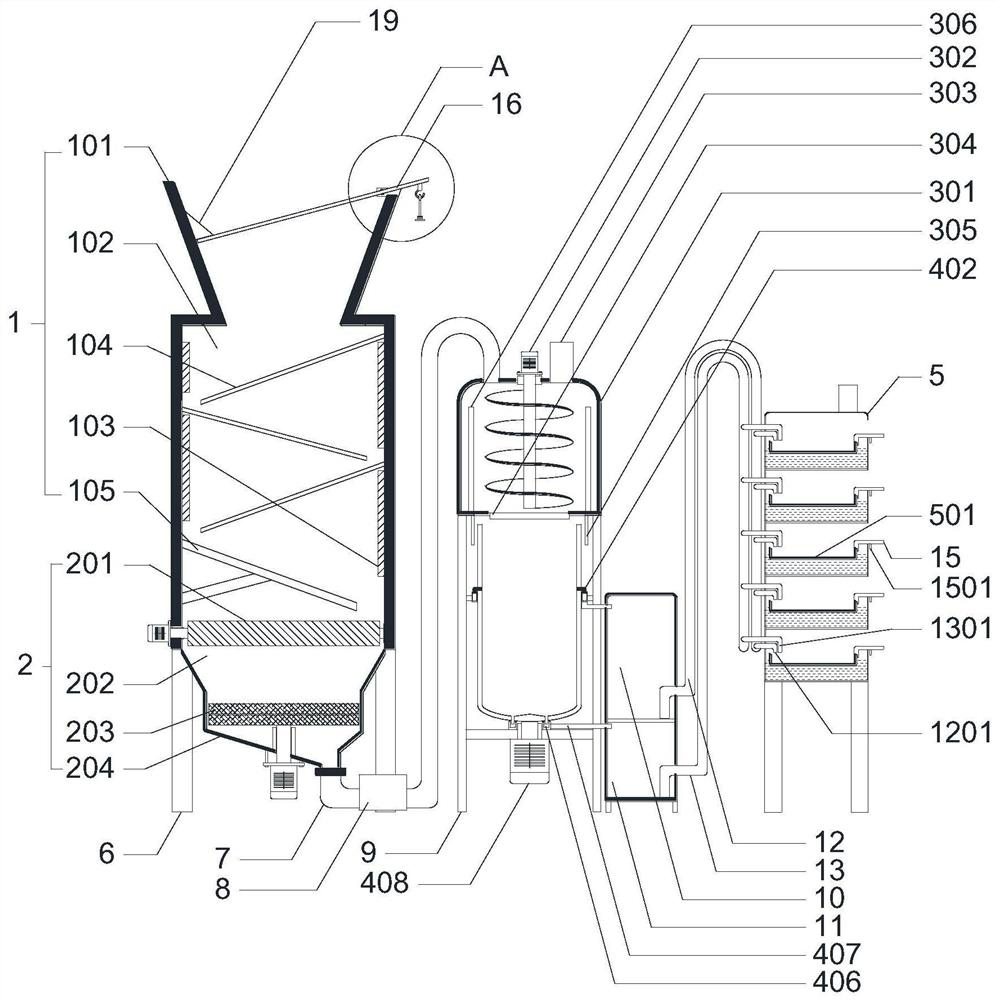

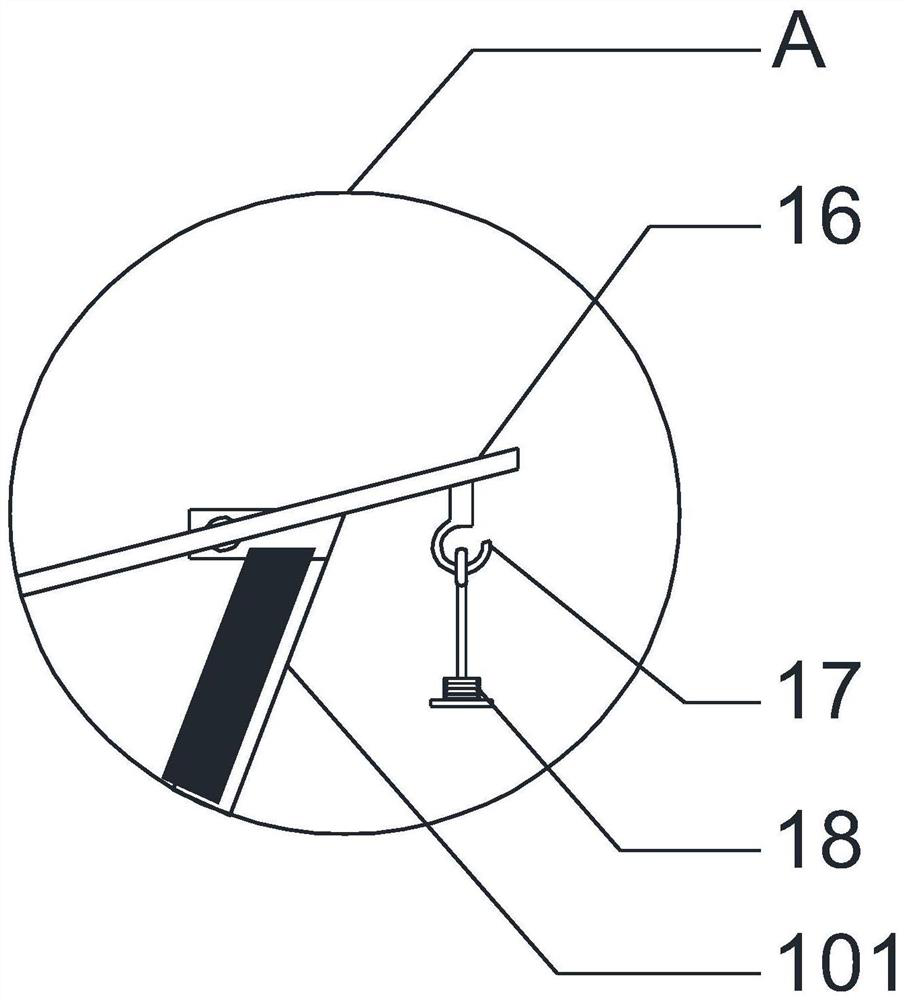

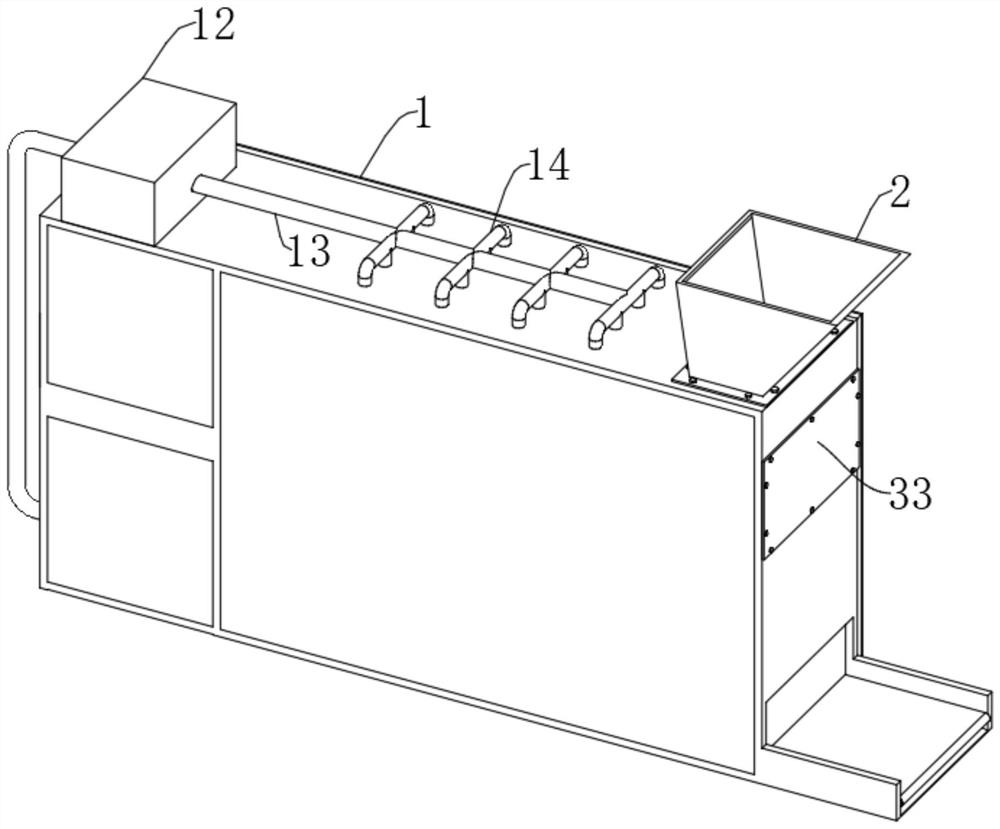

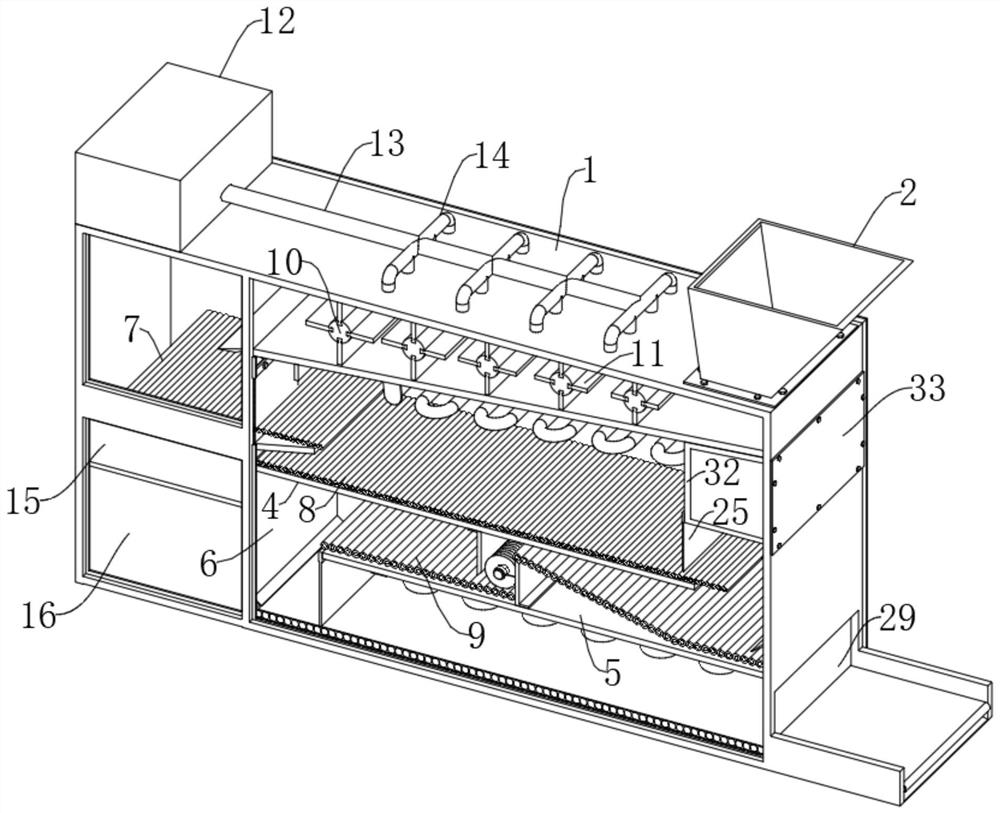

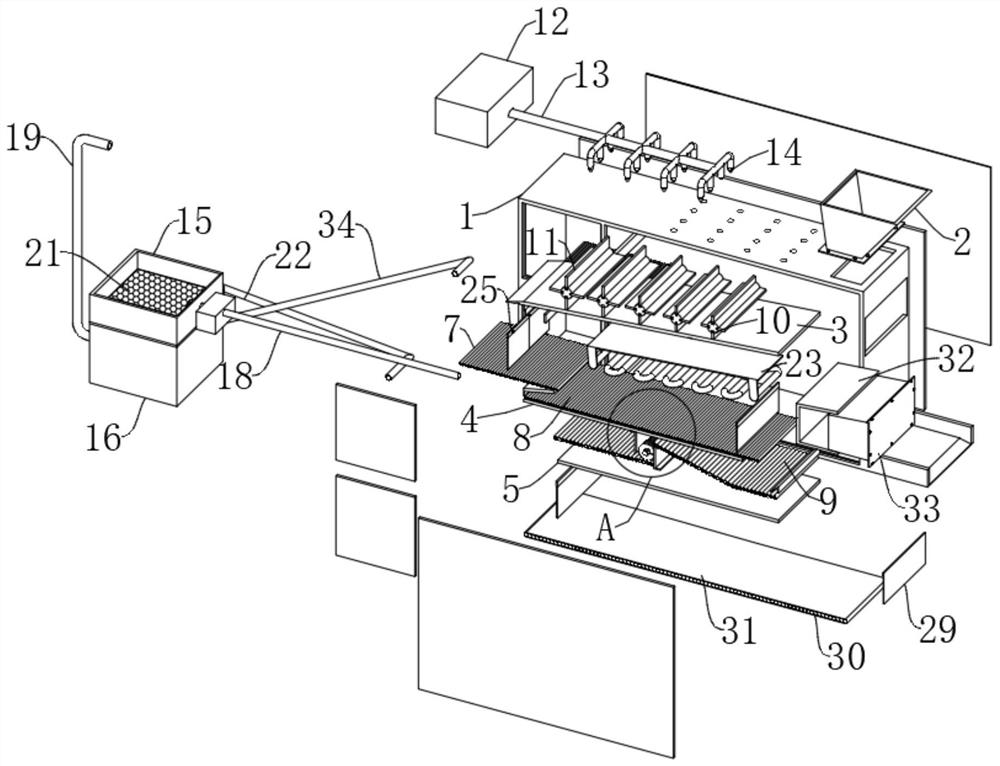

Air energy production line intelligent drying device

PendingCN111721035ADry evenlyReduce drying effectHeat pumpsDrying gas arrangementsProduction lineThermodynamics

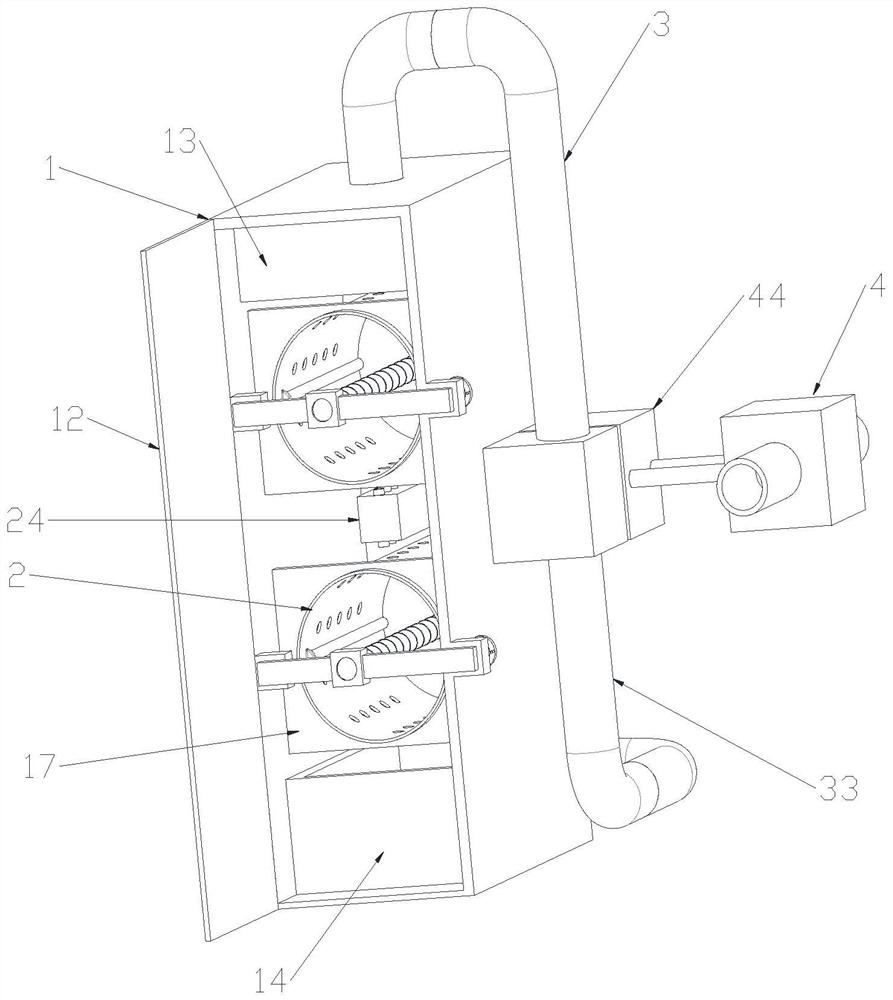

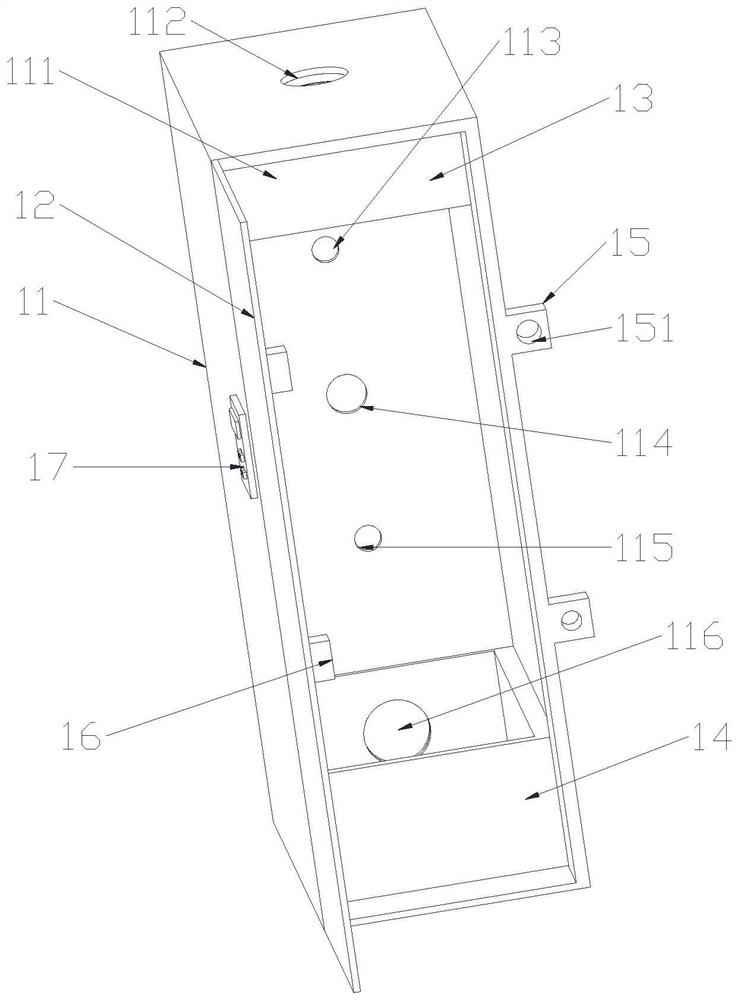

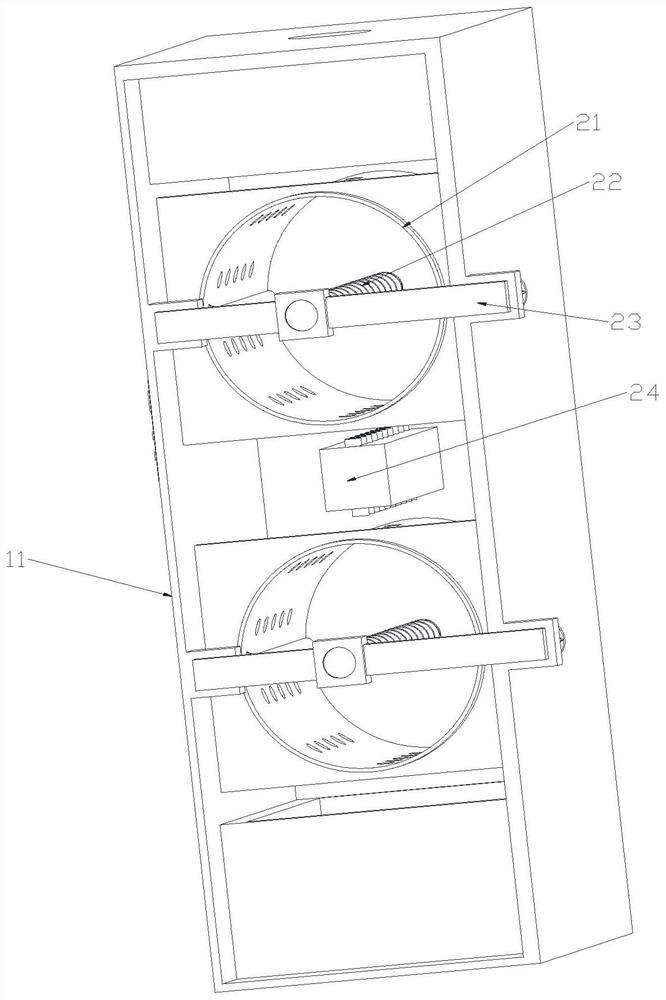

The invention relates to an air energy production line intelligent drying device comprising a drying room (1) and an automatic feeding elevator (2) installed on the side of the drying room (1). A feedinlet (8) is formed in the upper portion of one side of the drying room (1). A discharge outlet (6) is formed in the lower portion of the other side of the drying room (1). A discharge opening of theautomatic feeding elevator (2) corresponds to the feed inlet (8). The drying room (1) comprises a drying box (11), a fan, a condenser (13), a power mechanism (14), a production line mesh belt and anelectric auxiliary heater (17), and the fan, the condenser (13), the power mechanism (14), the production line mesh belt and the electric auxiliary heater (17) are installed in the drying box (11). The air energy production line intelligent drying device has the advantages that the dryer condenser and the electric auxiliary heater are adopted for drying simultaneously, the advantages of even drying, high efficiency, energy saving and the like are achieved, the dryer condenser and the electric auxiliary heater are matched mutually and are combined with production line operation into a whole, alarge amount of space is saved, a large amount of manufacturing cost is reduced, and meanwhile transport is convenient.

Owner:中能鑫凯(山东)节能科技有限公司

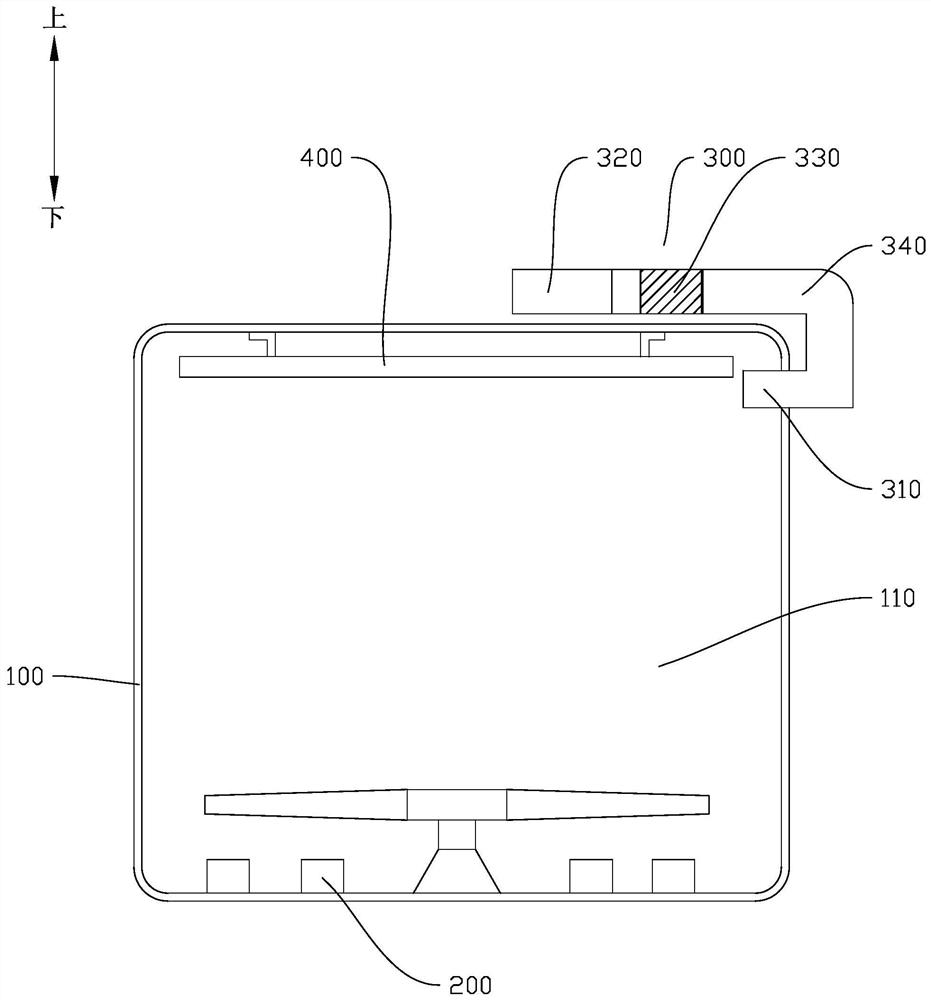

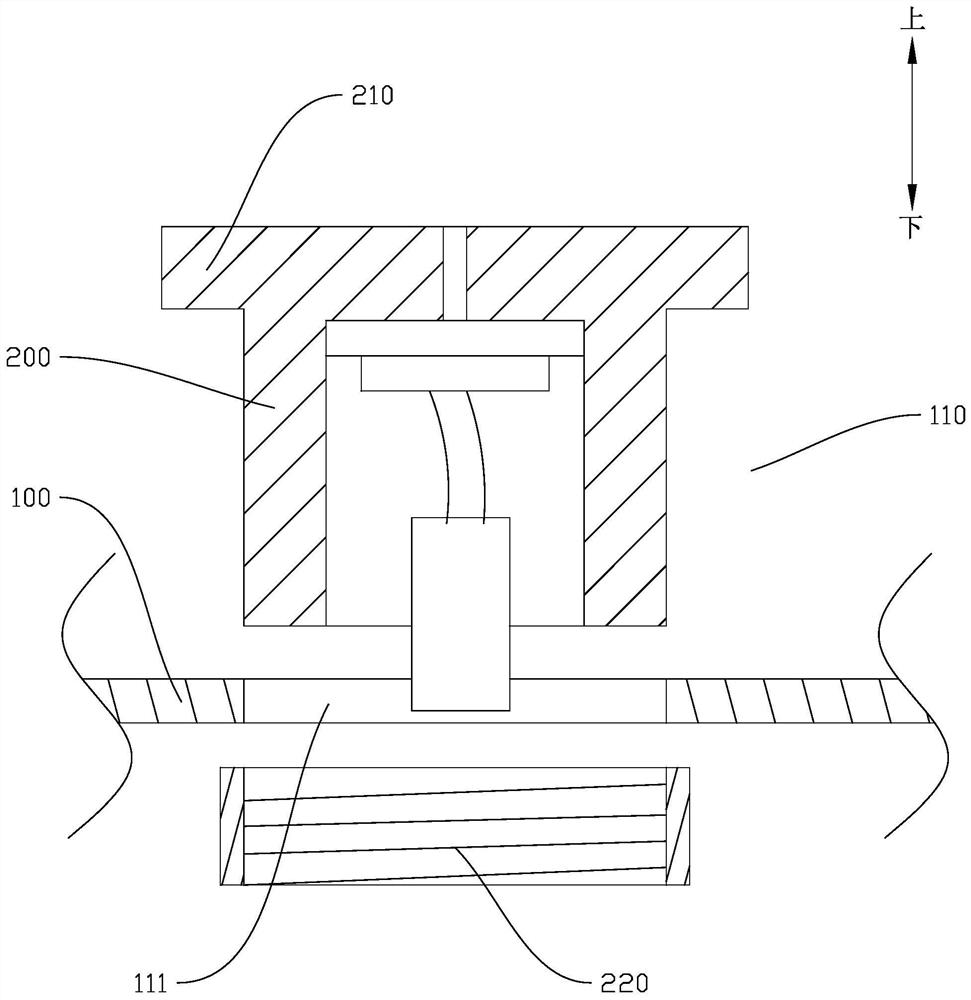

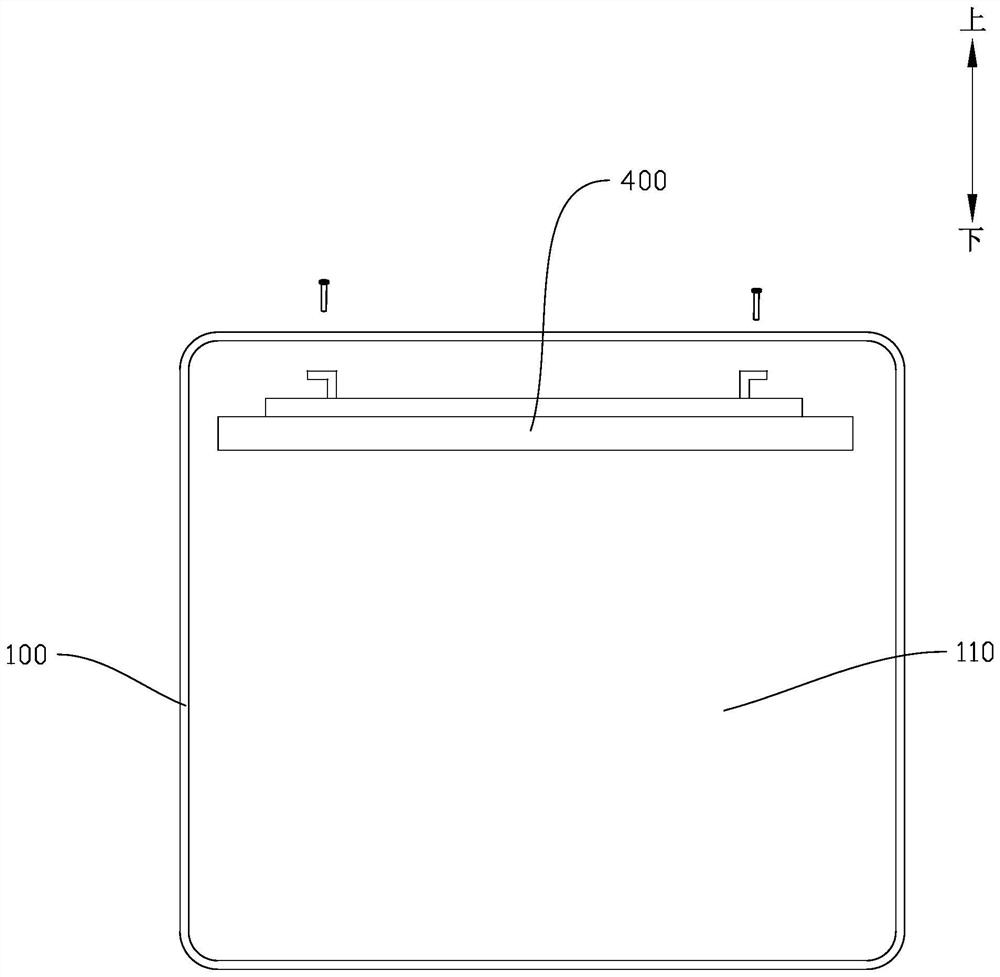

Dish washing machine drying device and drying method

PendingCN112656340AShorten drying timeReduce humidityTableware washing/rinsing machine detailsHigh humidityProcess engineering

The invention discloses a dish washing machine drying device, which comprises an inner container with an accommodating inner cavity; an ultrasonic vibrator, which is arranged at the bottom of the accommodating inner cavity; an ultrasonic reflector, which is arranged at the top of the accommodating inner cavity, and is located above the ultrasonic vibrator; and a hot air device, which is provided with an air outlet, wherein the air outlet is communicated with the accommodating inner cavity, and the air blowing direction of the air outlet faces the position between the ultrasonic vibrator and the ultrasonic reflector. According to the dish washing machine drying device, few water drops are left on tableware, and the tableware drying time of the dish washing machine drying device is greatly shortened. The invention further discloses a drying method using the dish washing machine drying device. According to the drying method, it is avoided that the humidity in the accommodating inner cavity is high, and the drying effect of the hot air device on tableware in the accommodating inner cavity can be weakened due to the too high humidity. The drying device can be applied to washing machines or flushing machines for pottery or tableware.

Owner:GUANGDONG VANWARD ELECTRIC

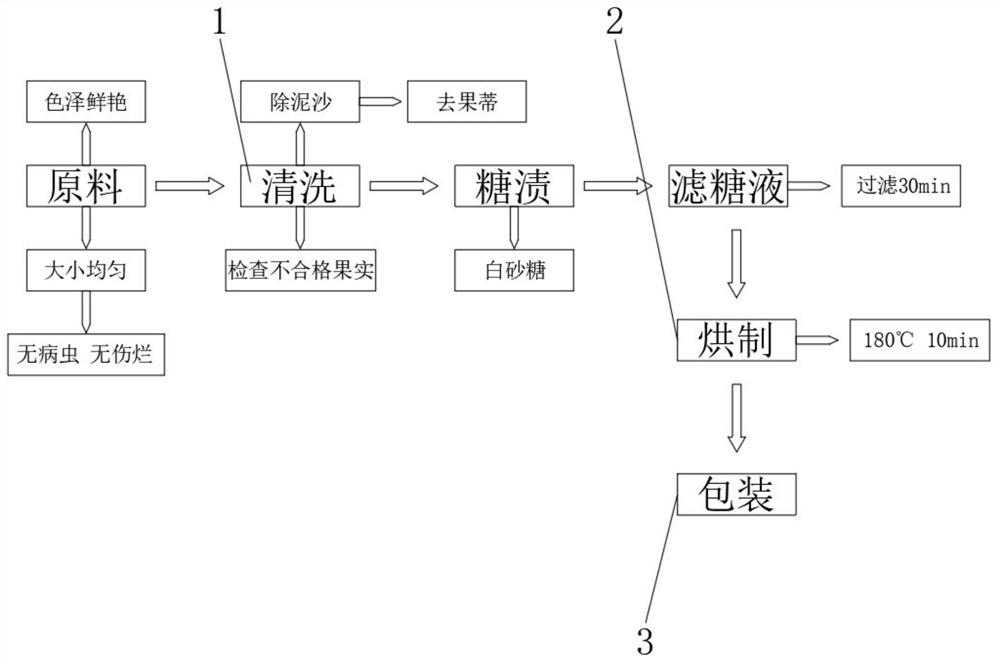

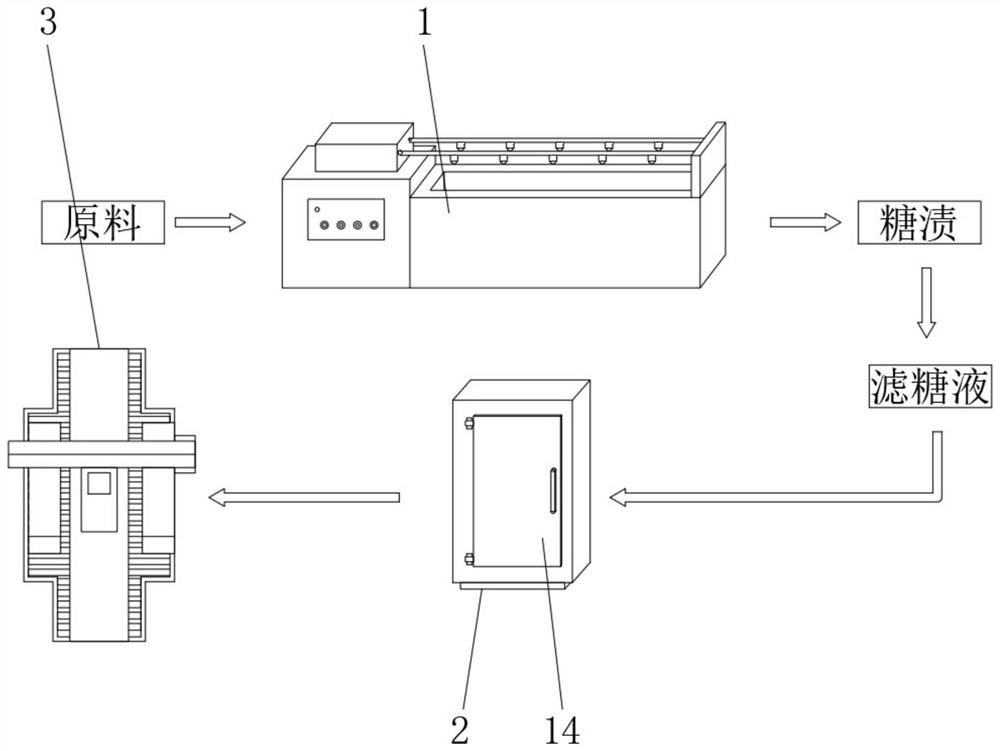

Dried strawberry product with high SOD (superoxide dismutase) enzyme activity and preparation method thereof

PendingCN113545409AUniform sizeImprove drying efficiencyConfectionerySweetmeatsFragariaSuperoxide dismutases

The invention discloses a dried strawberry product with high SOD enzyme activity and a preparation method thereof, which comprises a cleaning machine, a drying machine is arranged on the right side of the cleaning machine, a packaging machine is arranged on one side of the drying machine, fixing plates are transversely and fixedly connected to the top and the bottom of an inner cavity of the drying machine, the left side and the right side of the top of the inner wall of the fixing plate are movably connected with forward and reverse screws through bearing seats, the bottoms of the forward and reverse screws penetrate through the bottom of the fixing plate, and the tops and the bottoms of the surfaces of the forward and reverse screws are movably connected with shaft sleeves through threads. According to the invention, the problems of the existing drying equipment are solved, such as small strawberry contact area and slow action efficiency during high-temperature dehydration, increased power consumption and high production cost by using vacuum freeze-drying technology, no less than 20 hours of freeze-drying time and low efficiency, the processing cost loss of a user is reduced, the working efficiency of the drying equipment is increased, and the practicability of the drying equipment is also improved.

Owner:海澳思本源生物医药集团有限公司

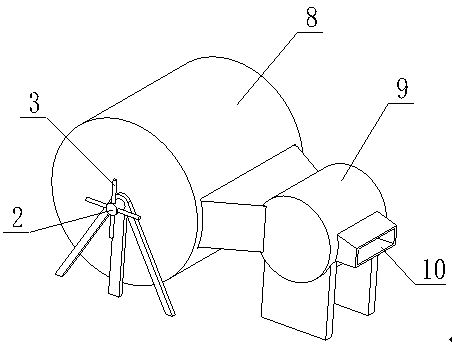

Food drying device

InactiveCN108645167AIncrease storage spaceImprove drying effectDrying gas arrangementsFood preservationImpellerDrying

The invention relates to the field of food equipment, in particular to a food drying device. The food drying device comprises a bracket, a rotating shaft, handles and a drying barrel; and the rotatingshaft is arranged on the bracket. The handles are arranged at the two ends of the rotating shaft of the food drying device; multiple cross beams are fixed between impellers; the cross beams are provided with multiple lifting baskets; the handles can be rotated to drive synchronous rotation of the multiple lifting baskets; through design of the multiple lifting baskets, the food storage space is enlarged, and the food drying space is saved; multiple ventilation holes are formed in the two sides of the lifting baskets to improve the food drying effect; a fan blows air into the drying barrel toaccelerate the drying effect; and foods are taken and placed in the lifting baskets by exhaust ports during exhausting. The food drying device is simple and scientific in structural design, saves thefood airing space, improves the food airing efficiency, and is suitable for popularization and application.

Owner:SUZHOU XINWEN FOOD

Annular microwave drying complete equipment

ActiveCN102980384BGuaranteed uptimeGuaranteed drying effectDrying solid materials with heatDrying machines with progressive movementsMicrowaveEngineering

The invention provides annular microwave drying complete equipment which comprises an annular microwave drying shell, M groups of microwave drying assemblies and an annular material conveying device, wherein the M groups of microwave drying assemblies are installed on the top of the annular microwave drying shell; a feed port and a discharge port are formed in the side wall of the annular microwave drying shell; a dehumidifying mouth is formed in the top of the annular microwave drying shell; the annular material conveying device comprises an annular material conveying platform, a plurality of groups of platform supporting rollers, an annular chain and N groups of power plants, wherein the platform supporting rollers are arranged in an annular shape, the annular chain is installed on the annular material conveying platform, and the N groups of power plants are arranged on one side of the annular chain; an annular protective cover is installed on the annular microwave drying shell, and the microwave drying assemblies are arranged in the annular protective cover; and a dehumidifying pipeline is installed in the dehumidifying mouth, and the outer end of the dehumidifying pipeline penetrates through the annular protective cover. The annular microwave drying complete equipment has the advantages of scientific design, less occupied area, good drying effect, convenience in production supervision and control and stability in operation.

Owner:信阳市四通机械制造有限公司

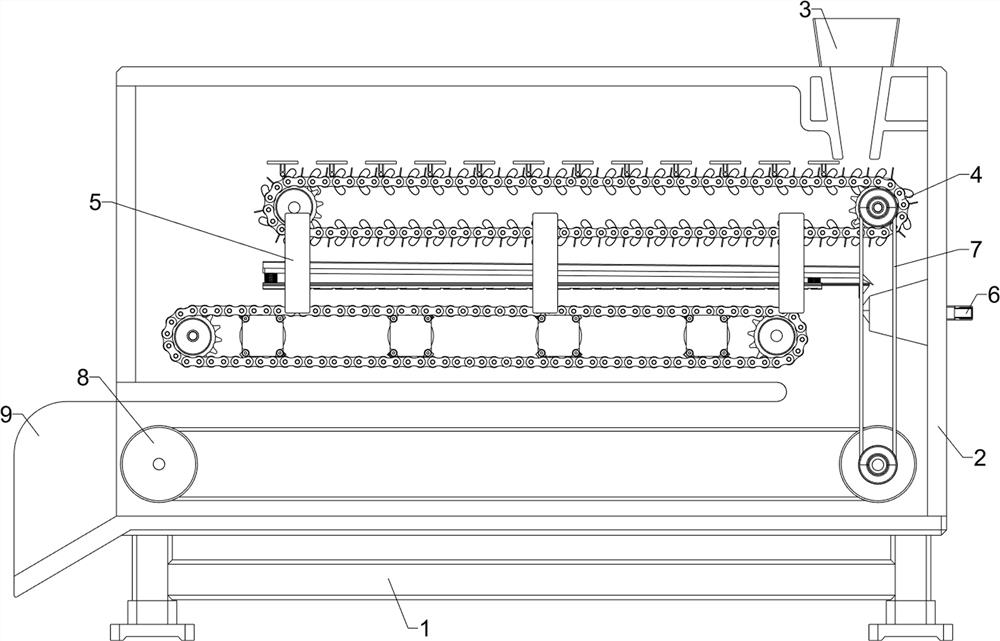

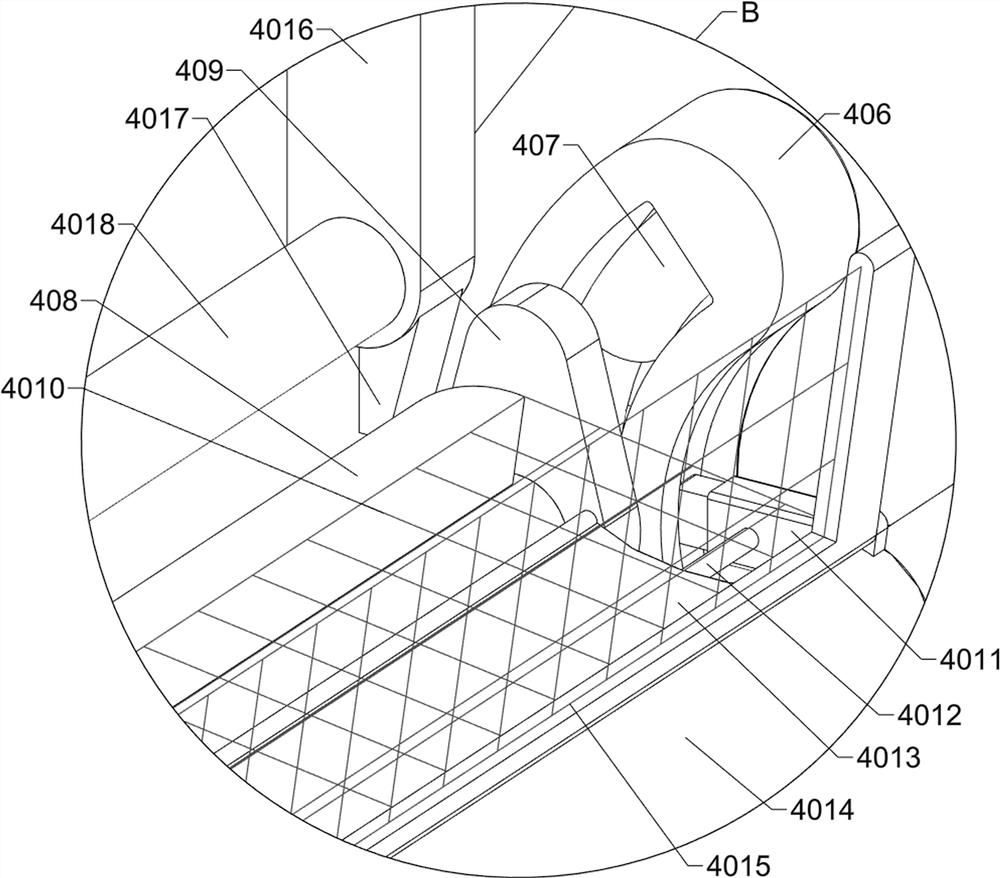

Rolling type drying equipment for new granular materials

InactiveCN113606920AReduce qualityIncrease contact areaGranular material dryingDrying gas arrangementsClassical mechanicsStructural engineering

The invention belongs to the technical field of new material production equipment, and particularly relates to rolling type drying equipment for new granular materials. The rolling type drying equipment comprises a hopper, a discharging opening, a power component and a conveying component. According to the rolling type drying equipment, the conveying component is driven by the power component to move, when the conveying component moves, a friction wheel moves relative to a friction frame, under the action of friction force, the friction wheel rotates, then a conveying roller rotates, and granular materials making contact with the conveying roller roll over under the action of the friction force, so that rolling movement of the materials is achieved while the granular materials are flatly laid on the conveying component at a thin layer thickness along with the movement of the conveying component, the granular materials make more uniform contact with hot air inside a shell, drying of the granular materials is more uniform, and the drying effect of the granular materials is improved.

Owner:邢金丽

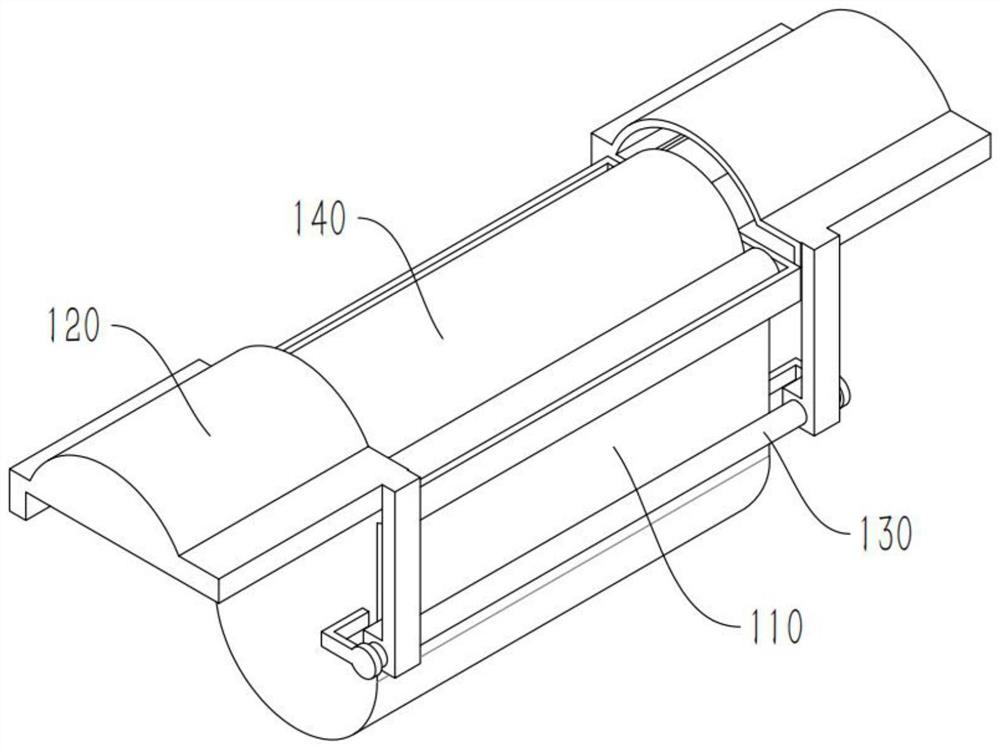

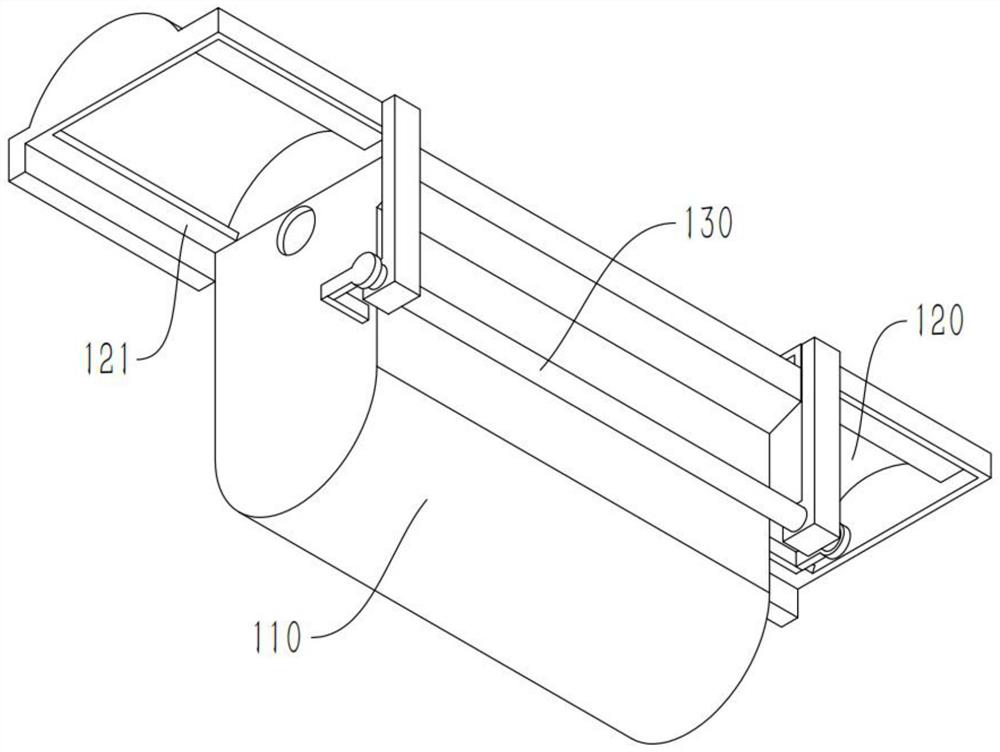

A cloth multi-level washing and drying integrated equipment

ActiveCN104153143BReduce clearanceIncrease concentrationSucessive textile treatmentsTextile treatment machine arrangementsTemperature stratificationWater-use efficiency

The invention discloses a cloth multi-level washing and drying integrated equipment, which comprises a water tank, a cloth releasing roller support, an adjustment switch, a transfer roller support, a front support roller support, a drying box, a rear support roller support and a fan. There are several temperature layered plates inside the dry box, and the temperature layered plates divide the drying box into an electric heating room and several drying rooms. There are a number of exhaust holes, the fan is connected to the electric heating chamber through the air pressure pipe, the water tank is divided into several cleaning chambers through the partition, and a serial flow port is arranged between the cleaning chambers, and the serial flow port is provided with Adjustment switch, the left end and the right end of the water tank are respectively provided with a water inlet and a water outlet, and the water inlet and the water outlet are respectively provided with an adjustment switch. The invention can complete the cleaning and drying of the cloth in sequence, has good cleaning effect, high water utilization rate, high drying efficiency, simple equipment structure and low investment cost.

Owner:XINCHANG COUNTY HENGDA CLOTHING MFG

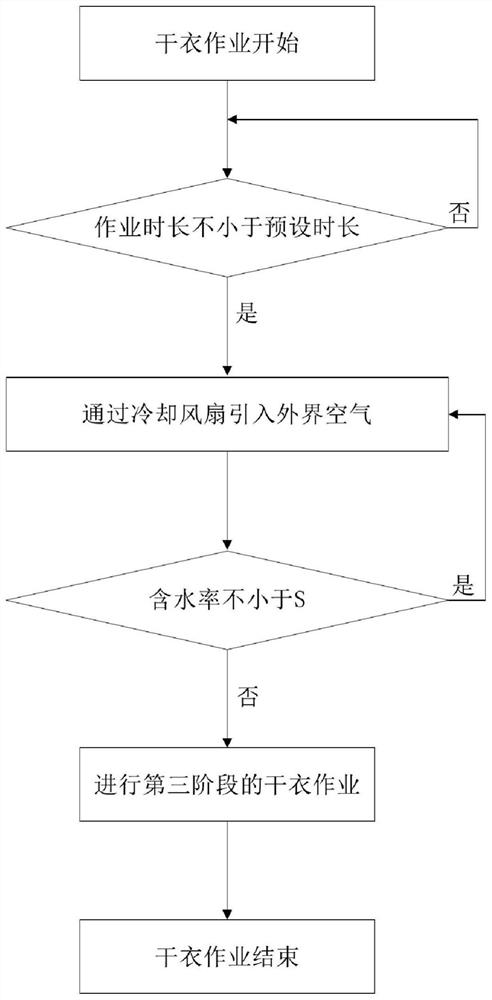

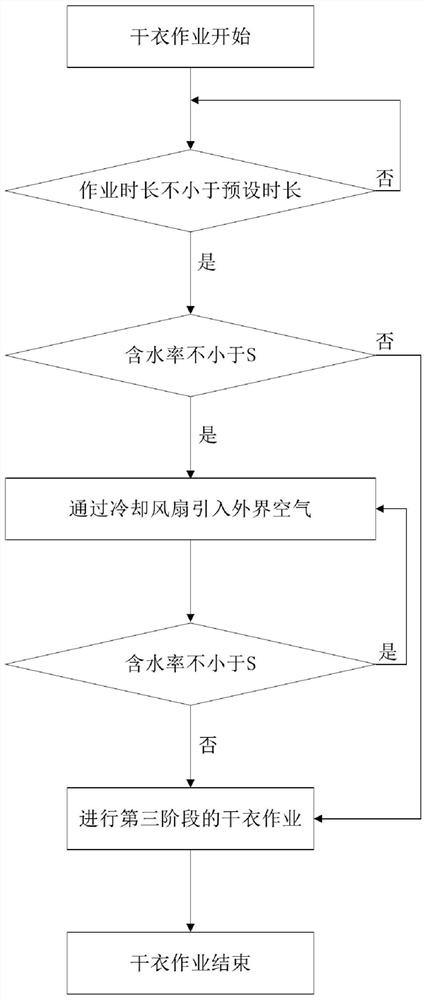

Condensed water controlling method of clothing treatment equipment and clothing treatment equipment

PendingCN111851019AReduce generationInhibitionTextiles and paperLaundry driersProcess engineeringEnvironmental engineering

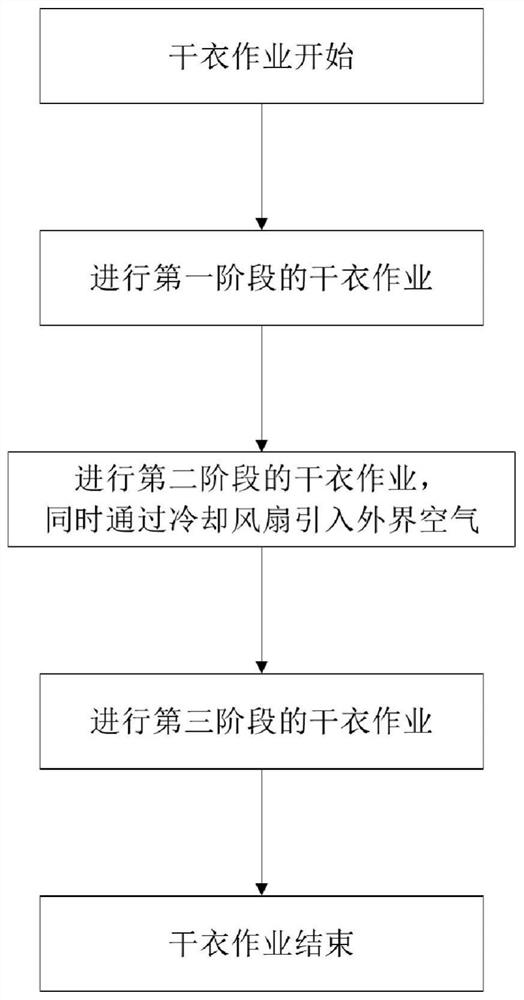

The invention belongs to the technical field of clothing treatment equipment, and discloses a condensed water controlling method of clothing treatment equipment and the clothing treatment equipment. The condensed water controlling method of the clothing treatment equipment includes: a clothing drying process sequentially includes an initial stage, an intermediate stage and an end stage, outside air is introduced into the clothing treatment equipment through a cooling fan in the intermediate stage to suppress the generation of condensed water, and the clothing treatment equipment uses the condensed water controlling method of the clothing treatment equipment. According to the condensed water controlling method of the clothing treatment equipment and the clothing treatment equipment, in theclothing drying stage with relatively high wetness, external air is introduced to circulate the air in the clothing treatment equipment, and the generation of the condensed water can be simply and efficiently suppressed.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

A kind of masterbatch drying device

Owner:山东诺森塑胶有限公司

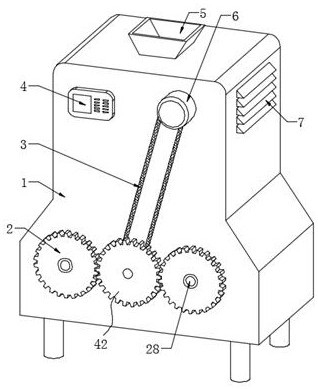

Color master batch drying device

ActiveCN111550980AExcellent adhesionAvoid heat treatmentSievingScreeningProcess engineeringIndustrial engineering

The invention relates to the field of color master batches, in particular to a color master batch drying device. The color master batch drying device comprises a bracket, a control screen, a feeding hole, a sieving mechanism, a smashing mechanism and a drying mechanism, wherein the control screen is arranged on the right part of the top end of the bracket. Through adoption of the color master batch drying device, drying of the color master batches in the falling process of the color master batches is realized, and degradation of the drying effect of internal color master batches due to adhesion enhancement of the color master batches caused by drying of the color master batches when the color master batches are piled is avoided. Uniform cooling treatment is performed on the color master batches, so that long-time high-temperature treatment of the color master batches is avoided, and the influence of inhalation of powdery color master batches flying in the air by human body on the health of operating personnel is avoided.

Owner:山东诺森塑胶有限公司

A raw material centrifugal impurity removal device with adjustable wind speed for edible oil processing

ActiveCN113000354BImprove the effect of impurity removalUniform and comprehensive removalSievingScreeningRotational axisEngineering

The invention relates to the technical field of edible oil processing, and discloses a raw material centrifugal impurity removal device with adjustable wind speed for edible oil processing, which includes a support ring, and an active tooth is rotatably connected to the inner center of the support ring. The rotating shaft of the tooth is fixedly connected with a swing rod, and one end of the swing rod is connected with a transmission gear in rotation, the inner side wall of the support ring is fixedly connected with an arc-shaped rack, and the output shaft of the transmission gear is fixedly connected with a cleaning cylinder. The transmission gear is driven to rotate by the arc-shaped rack, so that the transmission gear drives the cleaning cylinder to rotate, so that the angle of the cleaning cylinder changes, so that the cleaning cylinder can be more uniformly and comprehensively removed by the dryer. At the same time, the inside of the cleaning cylinder There are also elastic baffles and baffles. When the cleaning cylinder rotates, the raw materials are driven to shake under the action of the elastic baffles and baffles, so that the accumulated raw materials can be dispersed and the impurity removal effect of the raw materials is further improved.

Owner:青岛天祥食品集团有限公司 +1

Drying device for starch production

ActiveCN114593565AEasy to joinAvoid clumpingChemical industryDrying gas arrangementsProcess engineeringStarch production

The invention relates to the technical field of starch drying, in particular to a drying device for starch production, which comprises a drying box and further comprises a first partition plate, a second partition plate and a third partition plate, the stirring barrel is connected with the drying box and the first partition plate; the flow guide part is positioned in the drying box, and is matched with the stirring barrel; the drying mechanism is connected with the drying box, the first partition plate and the stirring barrel; wherein the drying mechanism comprises a hot air assembly, a crushing assembly and an equipartition assembly, the equipartition assembly comprises a driving unit, a hot air plate, a rotating cylinder and a containing groove, the drying device for starch production is novel in structure, easy to operate and high in automation degree, the situation that starch is stacked during drying, and then the drying effect is reduced can be avoided, and the drying efficiency is improved. The efficiency of drying work can be improved, and the phenomenon of caking of starch is avoided.

Owner:SHANDONG SHENZHOU XIANGYU TECH GRP

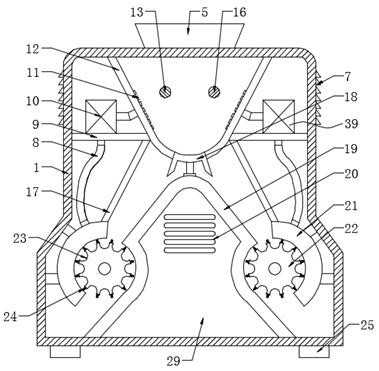

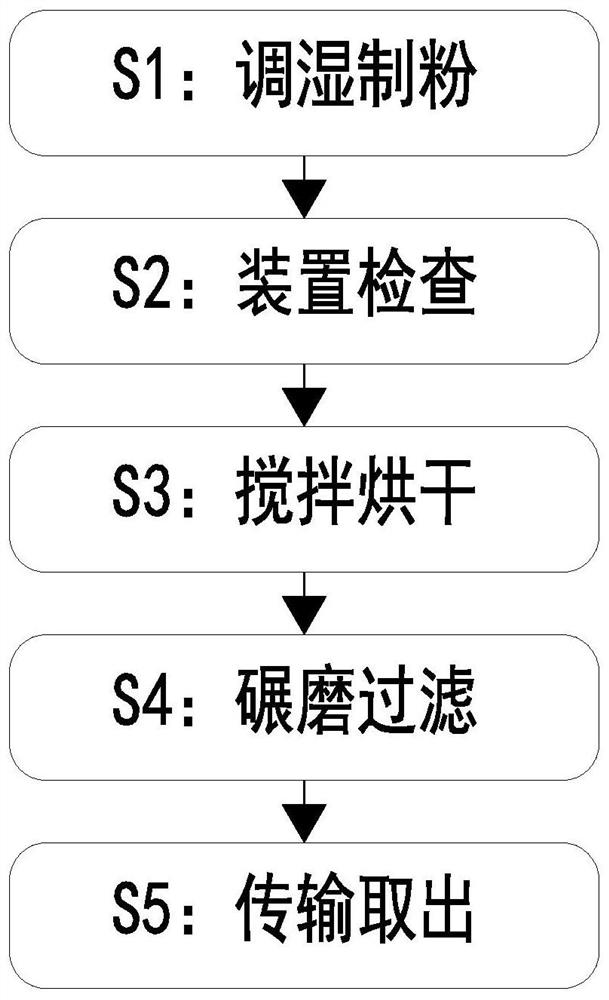

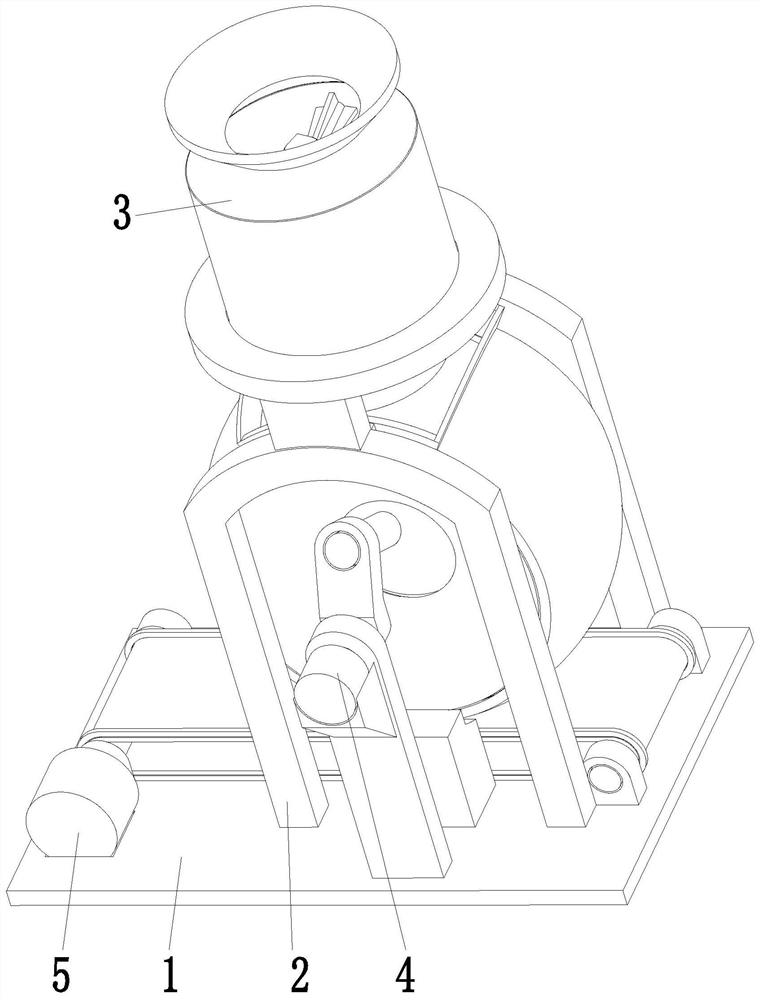

Industrial calcium carbonate preparation process

InactiveCN112939047AReduce drying effectImprove drying effectCalcium/strontium/barium carbonatesPhysical chemistryGrinding process

The invention relates to an industrial calcium carbonate preparation process. The industrial calcium carbonate preparation process adopts the following industrial calcium carbonate preparation device, wherein the industrial calcium carbonate preparation device comprises a base, U-shaped frames, a stirring and drying mechanism, a grinding and filtering mechanism and a transmission mechanism; the U-shaped frames of a U-shaped structure are symmetrically arranged on the right side of the upper end face of the base front and back; a stirring and drying mechanism and a grinding and filtering mechanism are sequentially arranged between the U-shaped frames from top to bottom, and a conveying mechanism is arranged on the portion, located between the U-shaped frames, of the upper end face of the base. The invention can solve the problems that in the drying and grinding process of industrial calcium carbonate in the prior art, due to the fact that limestone particles are not stirred and turned over during drying, the limestone particles on the lower layer are difficult to dry completely, and the drying effect on the industrial calcium carbonate is reduced; besides, the process of transferring the dried industrial calcium carbonate to a grinding machine is long, so that the grinding efficiency of the industrial calcium carbonate is influenced.

Owner:合肥高尧化工科技有限公司

Printing and laminating mechanical device

PendingCN110254044APlay the role of dryingReduce drying effectPrinting press partsPrinting inkPulp and paper industry

The invention discloses a printing and laminating mechanical device which comprises a laminating machine and a dedusting and dehumidifying device, wherein the laminating machine comprises a paper feeding table, and the dedusting and dehumidifying device is arranged across the upper part of the paper feeding table; the dedusting and dehumidifying device comprises an air inlet pipeline and an air outlet pipeline; the air inlet pipeline and the air outlet pipeline are respectively positioned on the two sides of the dedusting and dehumidifying device, and a current of hot air is formed between the air inlet pipeline and the air outlet pipeline; the top of the dedusting and dehumidifying device is inclined, and the dedusting and dehumidifying device also comprises a dust collection groove; and an electrostatic dedusting net is arranged in the dust collection groove. The printing and laminating mechanical device is applied to composition of printing paper and membranes and can pretreat the printing paper before laminating, so that the dedusting and dehumidification of printing paper is realized, and meanwhile the harmful gas volatilized by printing ink is recovered.

Owner:XIAN TECHNOLOGICAL UNIV

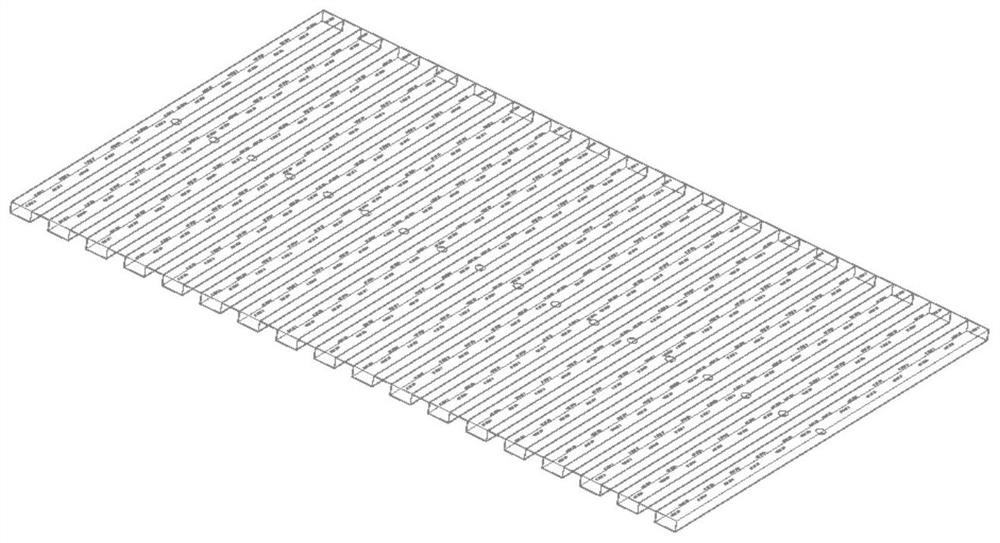

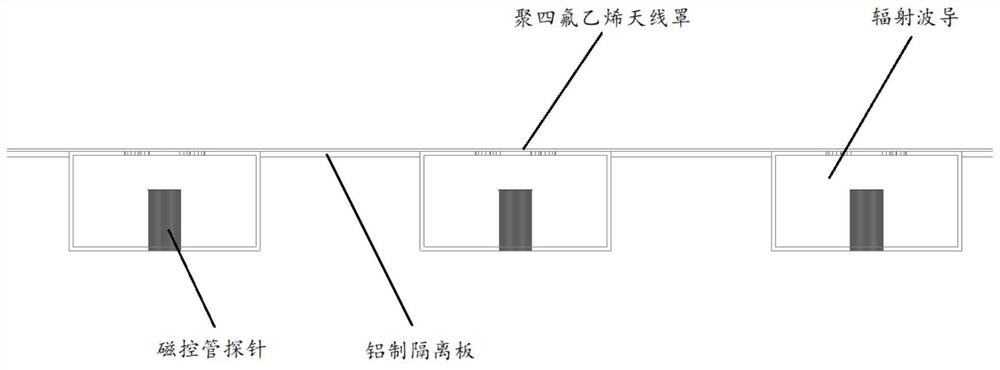

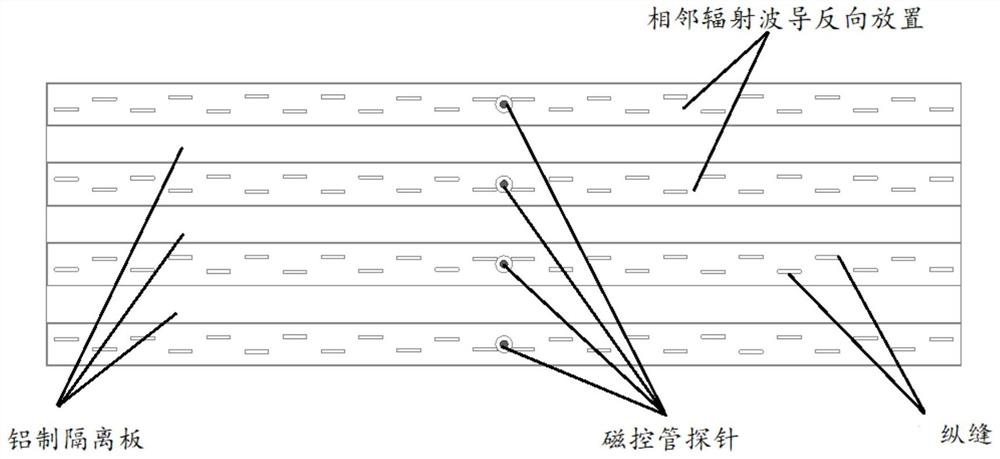

A High-efficiency Waveguide Slot Antenna Array for Base Cloth Drying

ActiveCN112616213BReach the total quantityReduce in quantityDrying solid materials with heatMicrowave heatingMicrowaveEngineering

The invention discloses a high-efficiency waveguide slot antenna array for base cloth drying, comprising: several radiation waveguides and several isolation plates arranged at intervals in sequence, the radiation waveguides are connected through the isolation plates; the radiation waveguides are connected by the isolation plates; A magnetron is fixedly connected inside, and the magnetron is arranged at the bottom of the radiation waveguide; several longitudinal slits are opened on the upper surface of the radiation waveguide, and the adjacent longitudinal slits are arranged in left and right staggeredly, and the radiation waveguide The lower surface is provided with a circular hole; the upper surface of the waveguide slot antenna array is covered with a radome. The radiation waveguide required by the present invention is a non-standard waveguide. Compared with the prior art, the size is smaller, the addition and subtraction and assembly are easier, and the microwave energy uniformity of the drying surface of the base cloth is high, the drying effect is good, and the energy utilization is high. High rate, low processing deviation requirements.

Owner:扬州玛克微尔科技有限公司

Purification equipment and process of tamarind extract

The invention discloses a purifying equipment and process of tamarind extract, belonging to the technical field of extract purification. A kind of equipment and process for purifying tamarind extract, comprising a drying device, a crushing device, a mixing device, a centrifugal device and an evaporation box, the drying device is composed of a feeding hopper, a drying bin, a heating plate and a sieve plate, the The feed hopper is arranged on the top of the drying bin, the heating plate is arranged on the inner wall of the drying bin, the sieve plate is arranged on the inner wall of the drying bin, and the lower part of the drying bin is arranged There is a guide plate, the crushing device is arranged at the lower part of the drying device, and the crushing device is composed of a roller, a cone bucket, a millstone and a collecting hopper, and the roller is arranged at the bottom of the drying bin, so The cone bucket is arranged at the bottom of the drying bin. In the drying process of the present invention, heat loss is reduced and energy is saved; incoming materials are screened according to their volumes, and different sizes have different drying times to obtain a suitable drying effect.

Owner:郑州市鑫磊香料有限公司

Anti-wrinkle anti-static fabric and preparation process thereof

PendingCN113373624APrevent drynessPrevent static electricityLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringMechanical engineering

The invention relates to the technical field of fabric preparation, in particular to an anti-wrinkle anti-static fabric and a preparation process thereof. The anti-wrinkle anti-static fabric preparation method of an anti-wrinkle anti-static fabric preparation system comprises the following steps of 1, soaking fabric through raw materials in a placing box II, carrying out anti-wrinkle treatment by soaking a resin raw material, and then extruding through two auxiliary rollers; 2, enabling the fabric to pass through the lower end of a bracket, heating and drying by multiple electric heating plates, and leveling by two leveling rollers in the drying process; 3, then enabling the fabric to pass through the upper end of a coating roller, and coating the fabric with an anti-static coating through the coating roller; and 4, enabling the fabric to enter the upper end of the bracket through multiple auxiliary rollers, and drying through the multiple electric heating plates again. The exposed size of the coating roller can correspond to the size of the fabric, and the situation that the part, not making contact with the fabric, of the coating roller is exposed in air, and raw materials are polluted can be avoided.

Owner:银河

Drying equipment for rhinitis medicinal materials

PendingCN114877622AAchieve dryingImprove drying efficiencyCuttersDrying chambers/containersBiotechnologyMedicinal herbs

The invention relates to the field of traditional Chinese medicine equipment, in particular to drying equipment for rhinitis medicinal materials. The technical problems that drying equipment cannot separate mutually hooked cocklebur fruits, the cocklebur fruits are in a spherical shape due to mutual hooking of the cocklebur fruits, during drying, the external cocklebur fruits and the internal cocklebur fruits are heated unevenly, internal leaves are heated and curled to wrap the cocklebur fruits during heating and drying, and in the drying process, the internal leaves are heated and curled to wrap the cocklebur fruits. The cocklebur fruits and the cocklebur fruits which are not wrapped by the wrapping leaves are not uniformly heated, and the leaves on the cocklebur fruits are difficult to clean. According to the technical scheme, the drying equipment for the rhinitis medicinal materials comprises a bottom frame, a heating bin and the like; a heating bin is installed on the upper portion of the underframe. According to the cocklebur fruit drying device, cocklebur fruits are dried, the mutually hooked cocklebur fruits are separated, leaves on the cocklebur fruits wrapped by the leaves are crushed in a rubbing mode, the cocklebur fruit drying efficiency is higher, and part of the leaves on the surfaces of the cocklebur fruits are cleaned.

Owner:陈华彬

Dryer control method, device and dryer

ActiveCN108679999BHigh degree of automation controlSolve the problem that the drying degree cannot be accurately controlledDrying solid materialsProcess engineeringMoisture

The invention discloses a control method and device of a drying machine and the drying machine. The method comprises the following steps that whether the moisture content change condition of air at anair inlet in a drying chamber of the drying machine reaches a set moisture content change condition or not is determined, and / or whether the weight change condition of a to-be-dried material reachesa set weight change condition or not is determined; and if the moisture content change condition of the air reaches the set moisture content change condition, and / or if the weight change condition ofthe to-be-dried material reaches the set weight change condition, the drying machine is shut down. According to the scheme, the defects that in the prior art, the manual labor amount is large, the drying effect is poor and the quality of the material cannot be guaranteed can be overcome, and the beneficial effects that the manual labor amount is small, the drying effect is good and the quality ofthe material can be guaranteed can be achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient steel wire online drying oven

InactiveCN111141127AEasy to useSave time at workDrying gas arrangementsDrying machines with progressive movementsElectric machineStructural engineering

The invention relates to the technical field of steel wire drying, and discloses an efficient steel wire online drying oven which comprises a drying oven body. Two supporting frames are fixedly connected to each of the two sides of the drying oven body, a transverse shaft is fixedly connected between the ends, away from the drying oven body, of every two corresponding supporting frames on the sameside, and the front face of each transverse shaft is movably connected with a bolt penetrating through the transverse shaft. According to the efficient steel wire online drying oven, a user can conveniently mount and dismount a wire winding barrel through the bolts and the transverse shafts; a steel wire can be limited in the middle of the drying oven body through auxiliary rollers and heat conduction pipes, the user can conveniently wind the wire through a transmission motor and a power wheel, and the working time of the user is shortened; and convection air blowing is carried out on the interior of the drying oven body through a rotating motor and fan blades in the drying oven body, so that heat in the drying oven body is more uniform, drying of steel wires is more efficient, the dryingtime is shortened, the working efficiency is improved, and use by a user is facilitated.

Owner:YANGZHOU JINCHEN STAINLESS STEEL MFR

Circulating double-layer dryer and drying method thereof

ActiveCN113047014BRealize automatic extractionAvoid direct contactTextiles and paperLaundry driersThermodynamicsProcess engineering

The invention relates to the technical field of clothes drying, in particular to a circulating double-layer dryer and a drying method thereof. The drying mechanism designed by the invention includes a drum, an extraction rod and a rotating nut. After the clothes are dried, the extraction rod can rotate with the drum and move outwards through the cooperation of the lead screw and the nut, so as to realize automatic extraction of clothes and avoid Workers come into direct contact with hot clothing. The first air collecting groove and the second air collecting groove designed by the present invention cooperate with the exhaust fan and the screen to directly enter the wet air after passing through the drum into the air outlet pipe to prevent the wet air from staying in the drying box and reducing the drying effect. The designed hot air circulation mechanism cooperates with the heat pump heating mechanism, which can circulate the air in the device, and at the same time use the heat pump to absorb the waste heat of the factory to heat the air, thereby reducing the energy consumption of the dryer, improving the energy utilization rate, and being more energy-saving and environmentally friendly.

Owner:浙江蓝鲸智能设备制造股份有限公司

A kind of processing equipment and processing method of traditional Chinese medicine in department of traditional Chinese medicine

ActiveCN113617714BFor long-term storageCause wasteDrying gas arrangementsCleaning using toolsMedicinal herbsForeign matter

The invention discloses a traditional Chinese medicine processing equipment and processing method of traditional Chinese medicine. The interior of the processing shell is provided with a separation chamber and a processing chamber from left to right through a partition plate. The feeding hopper is installed on the processing shell, and the bottom of the feeding hopper passes through the top of the processing shell and communicates with the processing chamber. Through the cleaning mechanism, the primary drying mechanism, the section cutting mechanism and the secondary drying mechanism, the medicinal materials are cleaned, the sludge on the surface of the medicinal materials is cleaned, and the surface of the medicinal materials is dried, and the medicinal materials are cut into sections after drying. The finished medicinal materials are dried again for a long time, so that the medicinal materials can be stored for a longer time, and it solves the problems that people have soil and other foreign matter, or has peculiar smell, or is toxic, or is not easy to store when they are wet, and the medicinal materials can be stored. Automatic finishing reduces the time of manual operation.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com