Annular microwave drying complete equipment

A technology of microwave drying and complete sets of equipment, which is applied in the direction of drying, drying machines, lighting and heating equipment, etc., can solve the problems of inconvenient production process supervision, etc., to facilitate production supervision, ensure drying effect, and good drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

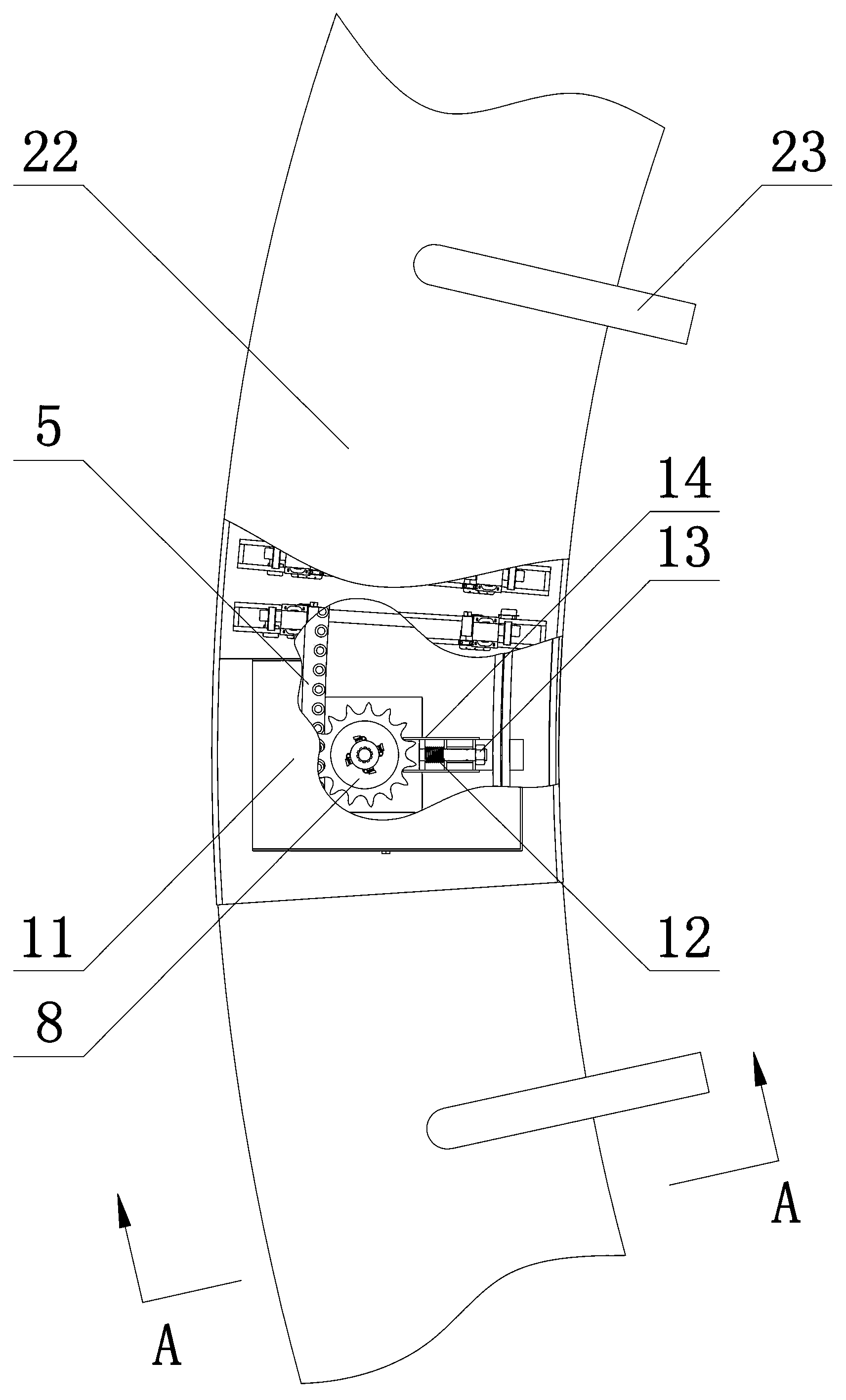

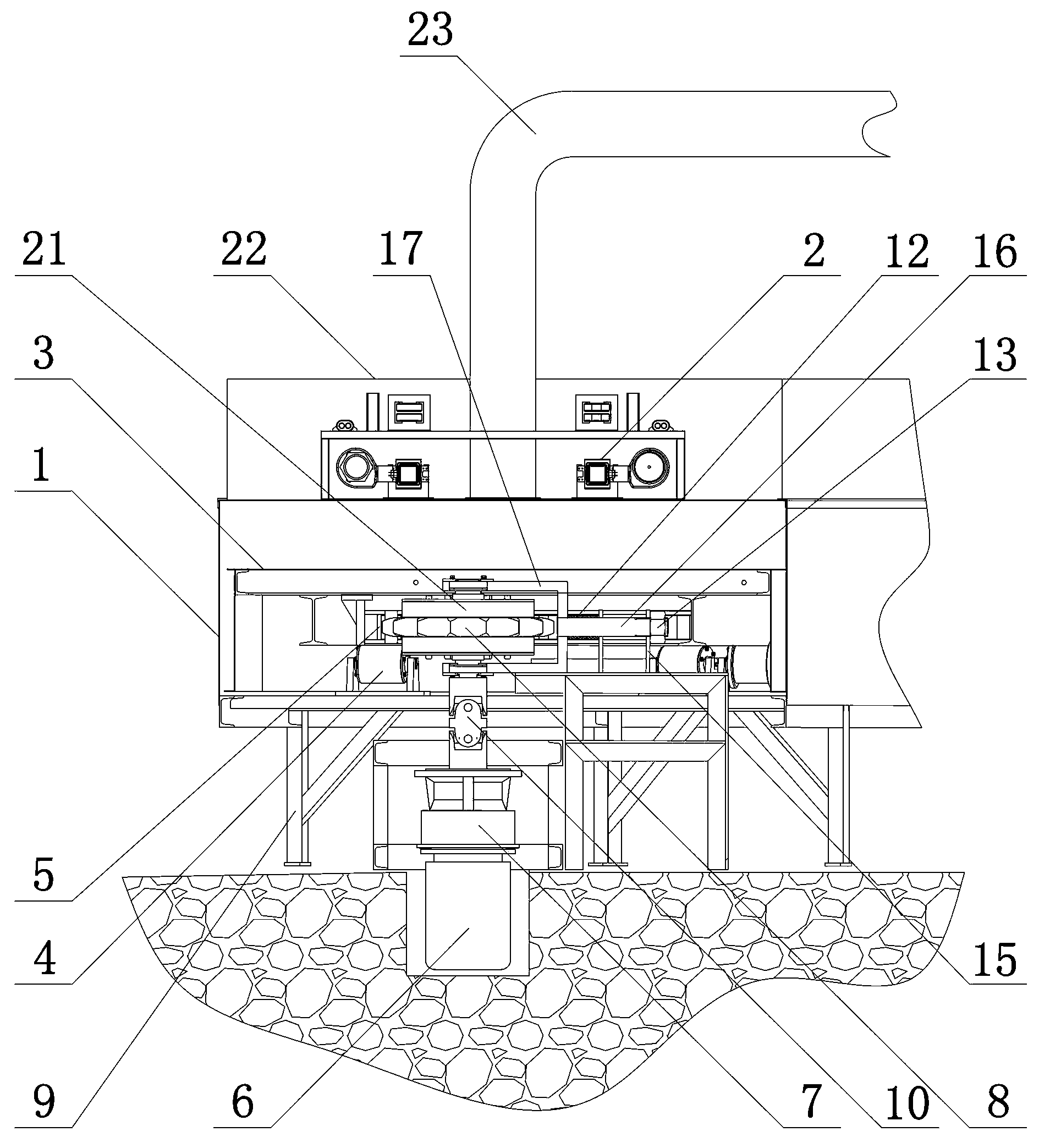

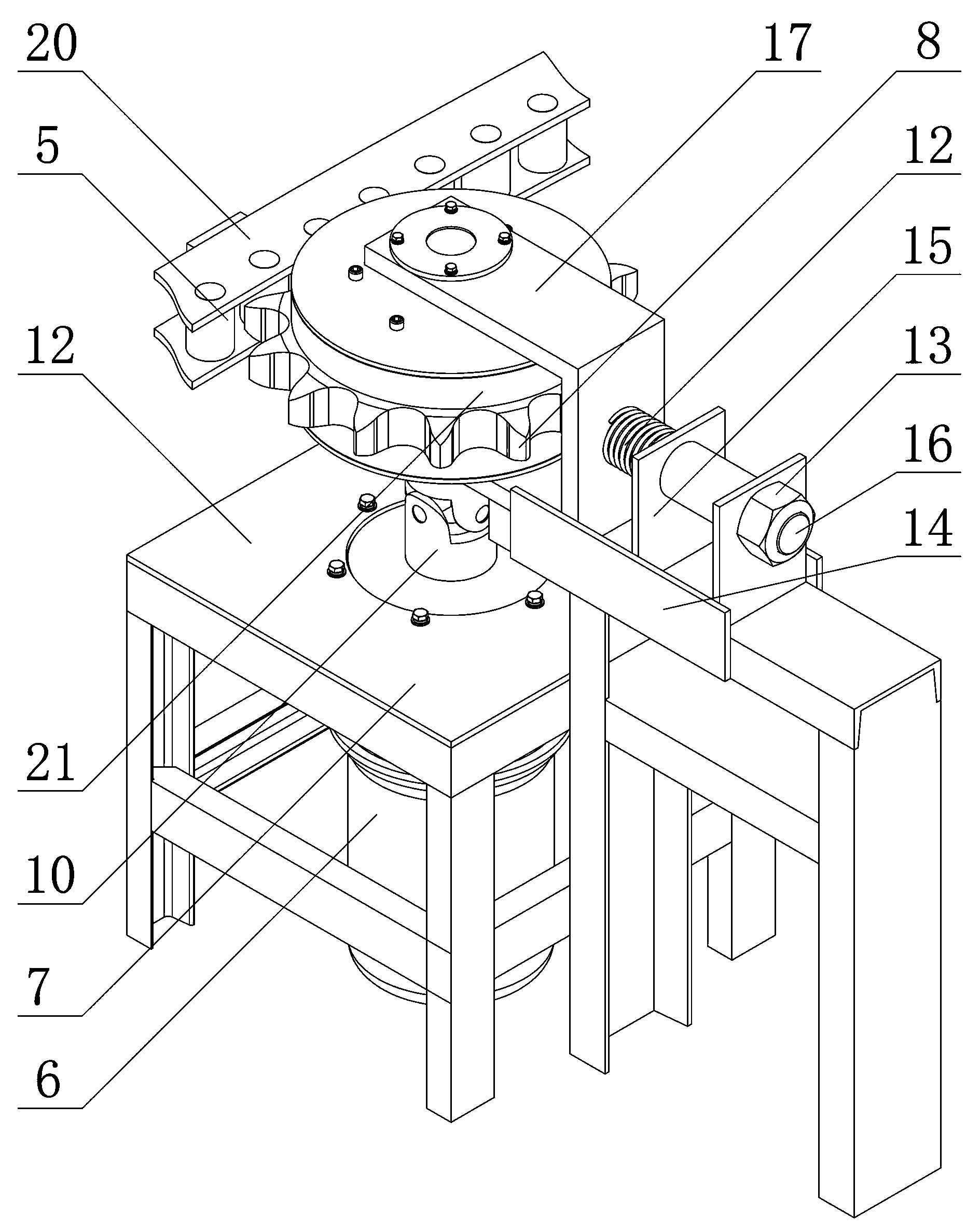

[0024] Such as figure 1 , figure 2 As shown, a complete set of annular microwave drying equipment, which includes an annular microwave drying shell 1, M groups of microwave drying components 2 and annular material conveying devices installed on the top of the annular microwave drying shell 1; The microwave drying assembly 2 is evenly arranged along the annular microwave drying shell 1 to achieve uniform radiation and ensure a drying effect.

[0025] The side wall of the annular microwave drying shell 1 is provided with a material inlet and a material outlet, and the top of the annular microwave drying shell 1 is provided with a dehumidification port for discharging moisture generated during drying.

[0026] The annular material conveying device includes an annular material conveying platform 3, a plurality of sets of platform rollers 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com