Annular gas drying complete equipment

A complete set of equipment and ring-shaped technology, which is applied in the field of ring-shaped gas drying complete sets of equipment, can solve the problems of inconvenient production process supervision, and achieve the effects of convenient production supervision, scientific design, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below through specific implementations.

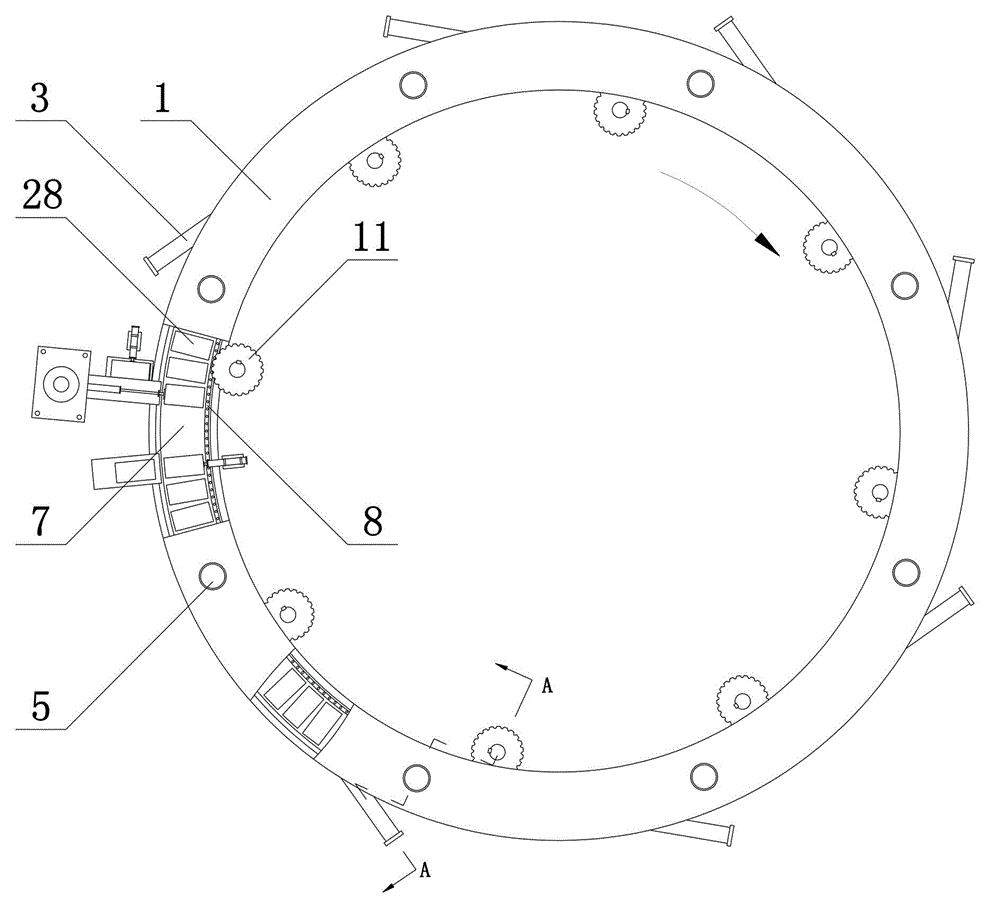

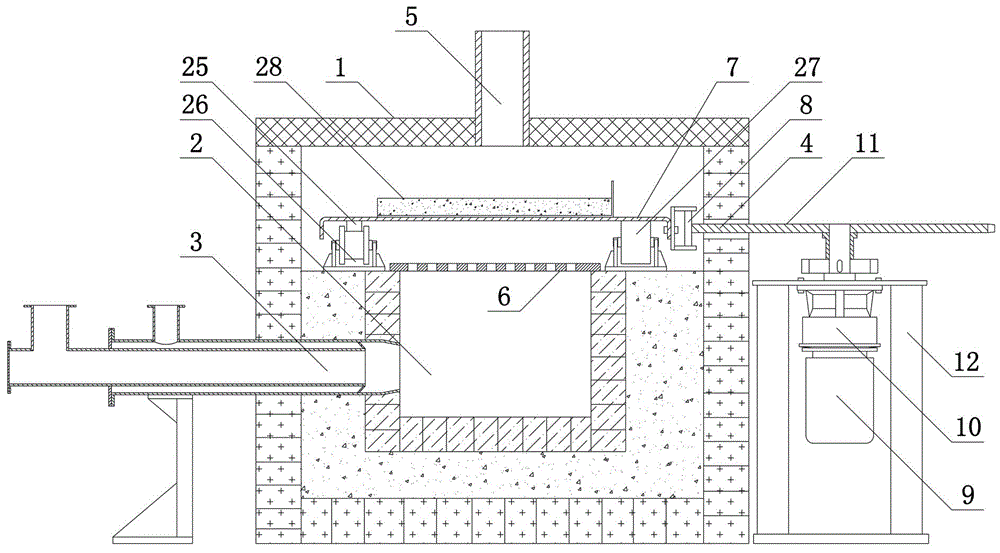

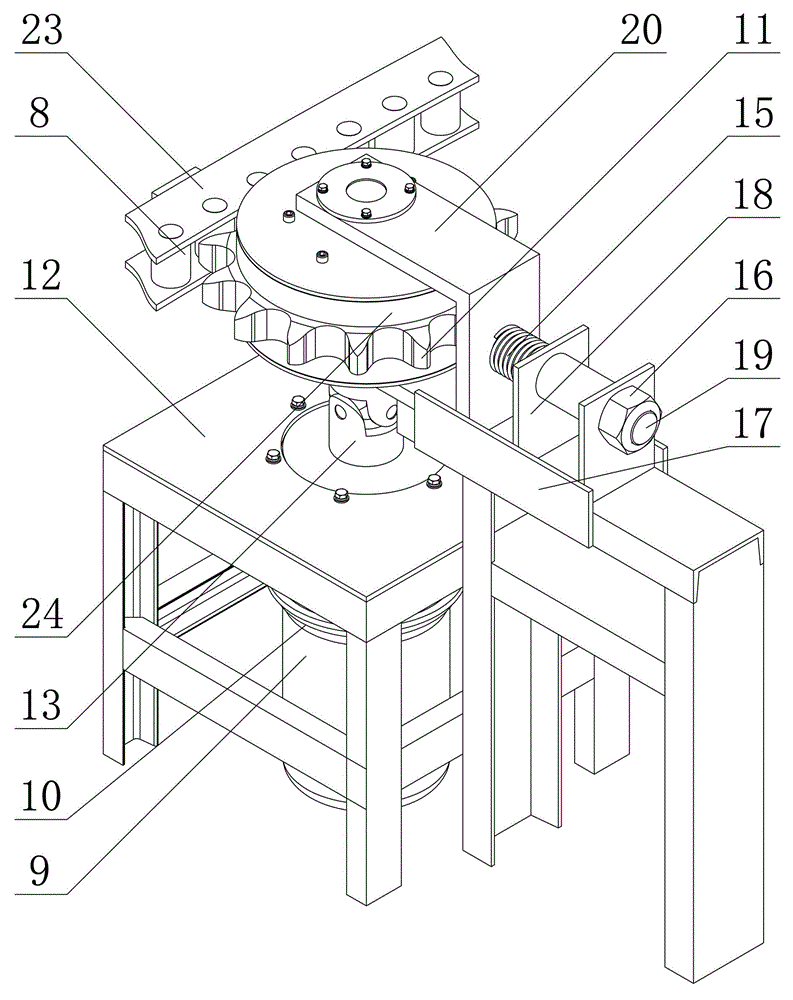

[0026] Such as figure 1 , figure 2 As shown, an annular gas drying complete set of equipment includes an annular heat preservation kiln and an annular material conveying device.

[0027] The ring-shaped heat preservation kiln includes a ring-shaped furnace body 1, an ring-shaped fire channel 2 and M burners 3 built in the ring-shaped kiln furnace body 1, and the ring-shaped fire channel 2 is made of refractory bricks. Therefore, a thermal insulation mortar is arranged between the annular fire channel 2 and the annular kiln body 1 to play a role of heat insulation and heat preservation. The side wall of the ring kiln body 1 is provided with a plate inlet, a plate outlet and N sprocket ports 4, and the sprocket ports 4 are arranged on the inner ring side wall of the ring kiln body 1; The top of the annular kiln body 1 is provided with a smoke exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com