Anti-wrinkle anti-static fabric and preparation process thereof

A fabric and electrostatic technology, which is applied in the processing of textile material equipment configuration, textile material processing, textile processing machine accessories, etc., can solve the problem of inability to adjust the size of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

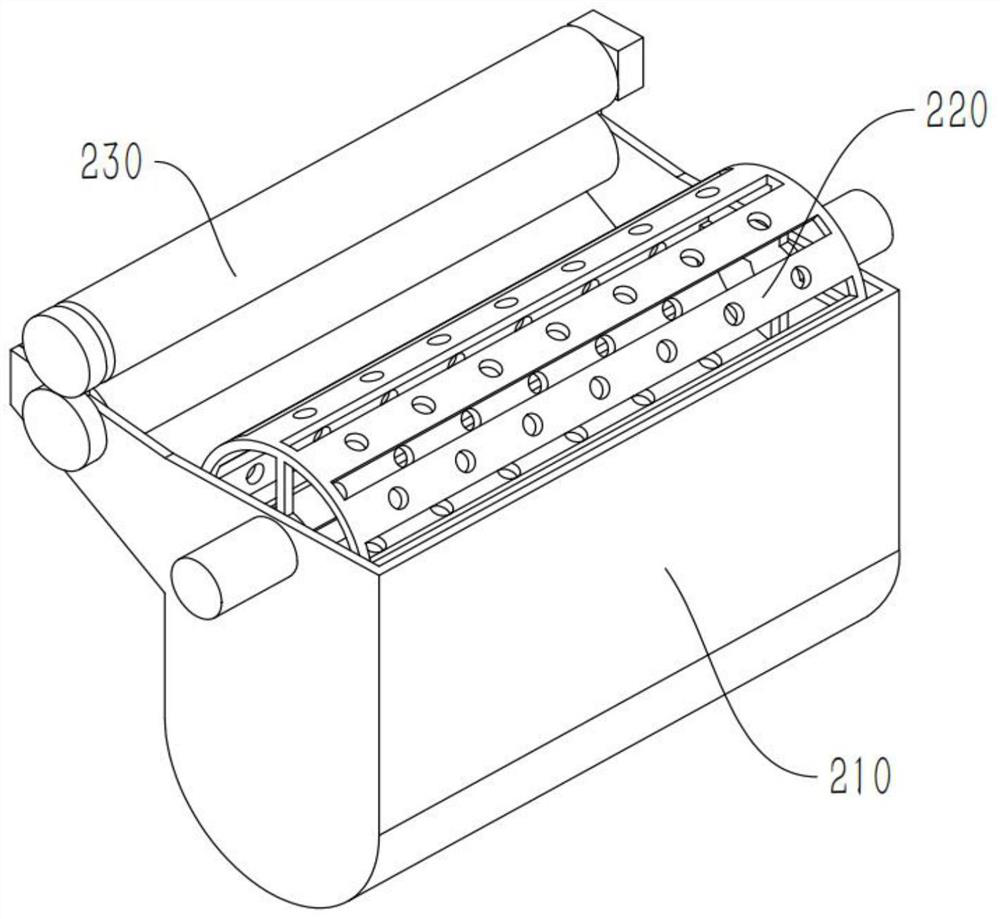

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

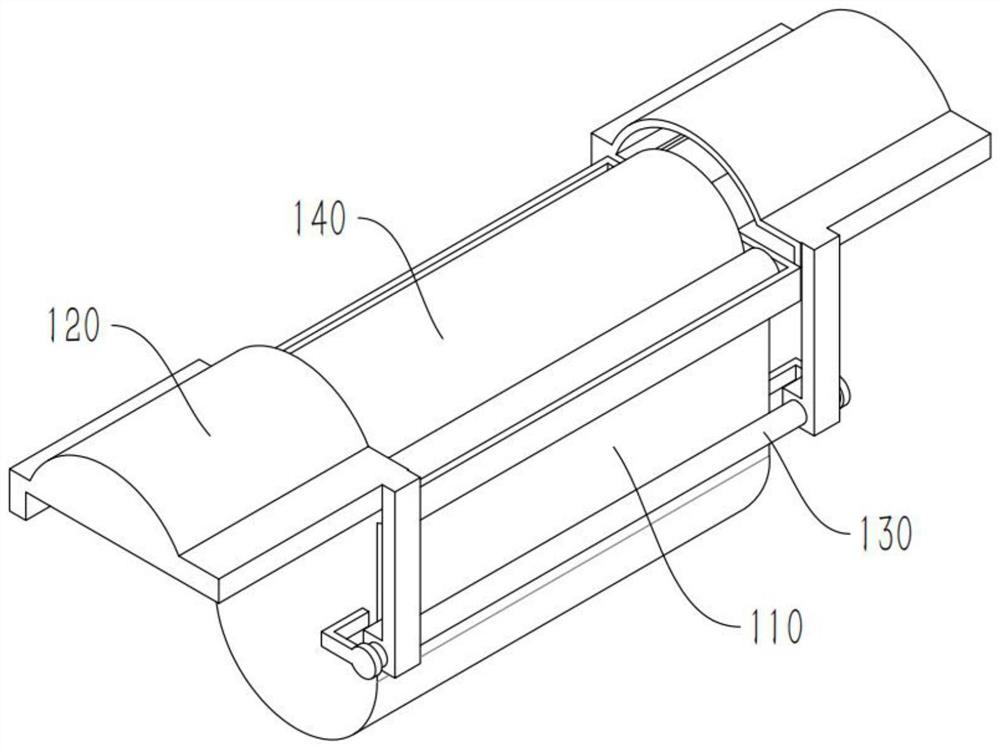

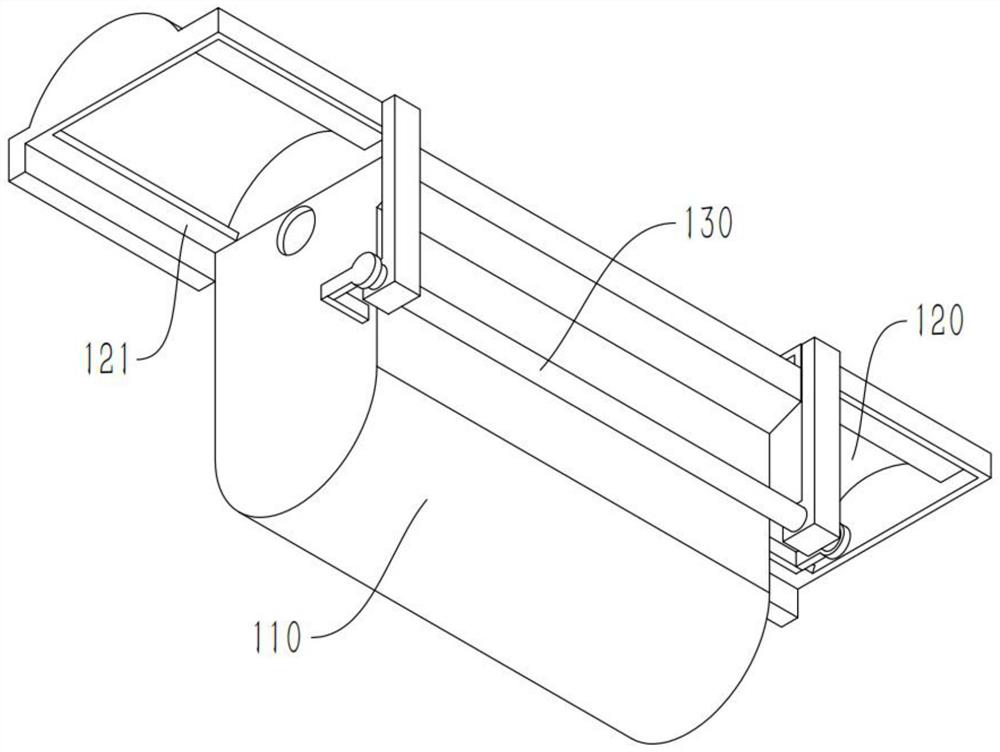

[0030] As shown in Figures 1 and 2,

[0031] The preparation system for anti-wrinkle and anti-static fabrics includes a placement box 110, a case cover 120, a lead screw 130 and an applicator roller 140. Above, the screw transmission between the two box covers 120 and the lead screw 130, the moving directions of the two box covers 120 are opposite, the smearing roller 140 is rotatably connected in the placement box 110, and the two box covers 120 are equipped with scrapers 121 , the lead screw 130 is driven by external power, and the external power is a deceleration motor, which is fixedly connected to the placement box 110, the lead screw 130 is fixedly connected to the output shaft of the deceleration motor, and the smearing roller 140 is driven by an external power. A deceleration motor is selected as the power, and the deceleration motor is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com