Cloth multi-layer washing and drying integrated equipment

A multi-level, cloth technology, applied in the direction of textile material equipment configuration, textile material processing, textile material continuous processing, etc., can solve the problems of complex structure, large equipment volume, high maintenance cost, etc., to achieve simple equipment structure, High energy utilization rate and good cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

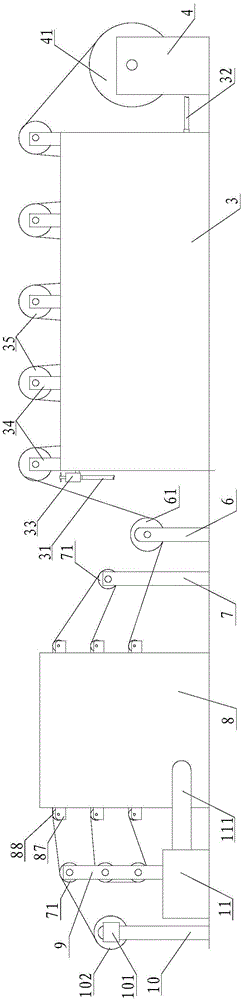

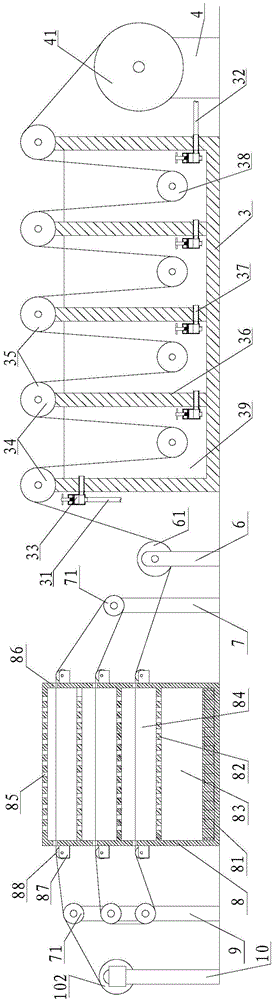

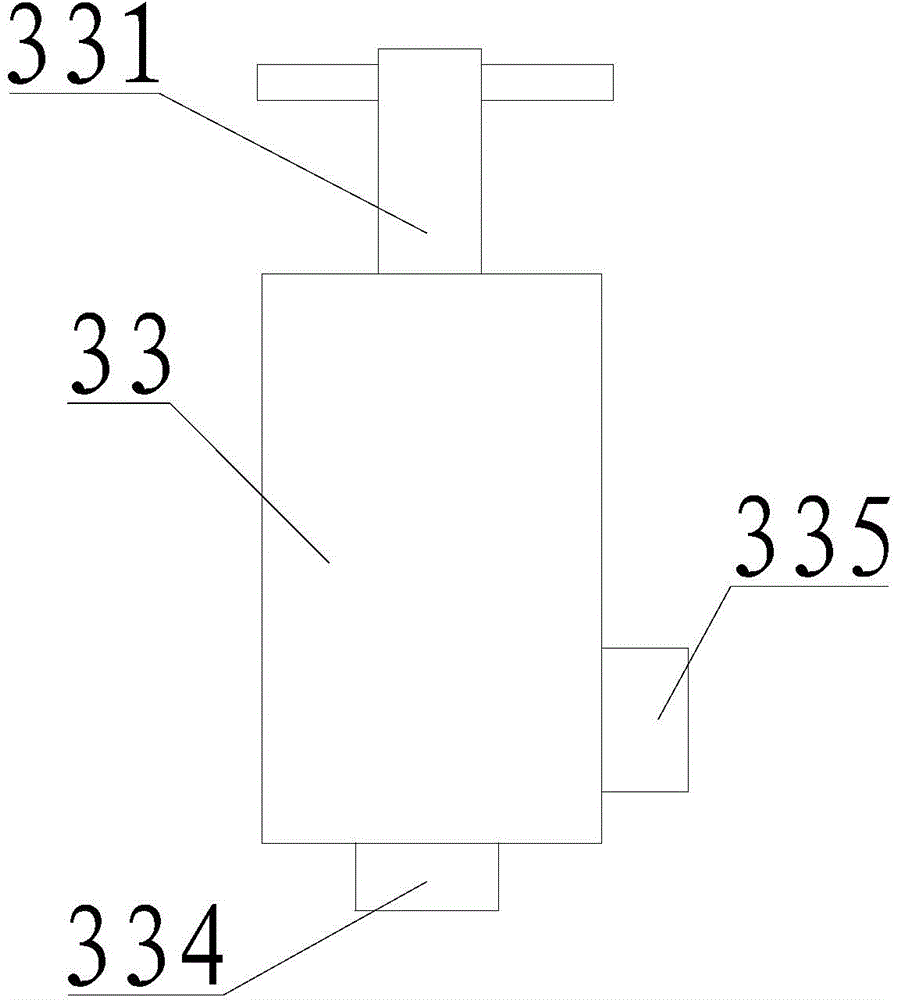

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention is an integrated multi-level washing and drying equipment for cloth, comprising a water tank 3, a cloth releasing roller bracket 4, an adjustment switch 33, a transfer roller bracket 6, a front supporting roller bracket 7, a drying box 8, and a rear supporting roller bracket 9 And blower fan 11, described drying case 8 interior is provided with several temperature stratification plates 82, and described temperature stratification plate 82 divides drying case 8 into an electric heating chamber 83 and several drying chambers 84, and described drying chamber 84 The two sides are respectively provided with cloth openings 86, and the temperature stratification plate 82 is provided with a number of exhaust holes 85, the fan 11 is connected with the electric heating chamber 83 through the air pressure pipe 111, and the left side of the drying box 8 is provided with a rear support roller bracket 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com