Color master batch drying device

A drying device and masterbatch technology, applied in the field of masterbatch, can solve problems such as uneven drying, affecting the health of operators, and enhanced adhesion of masterbatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

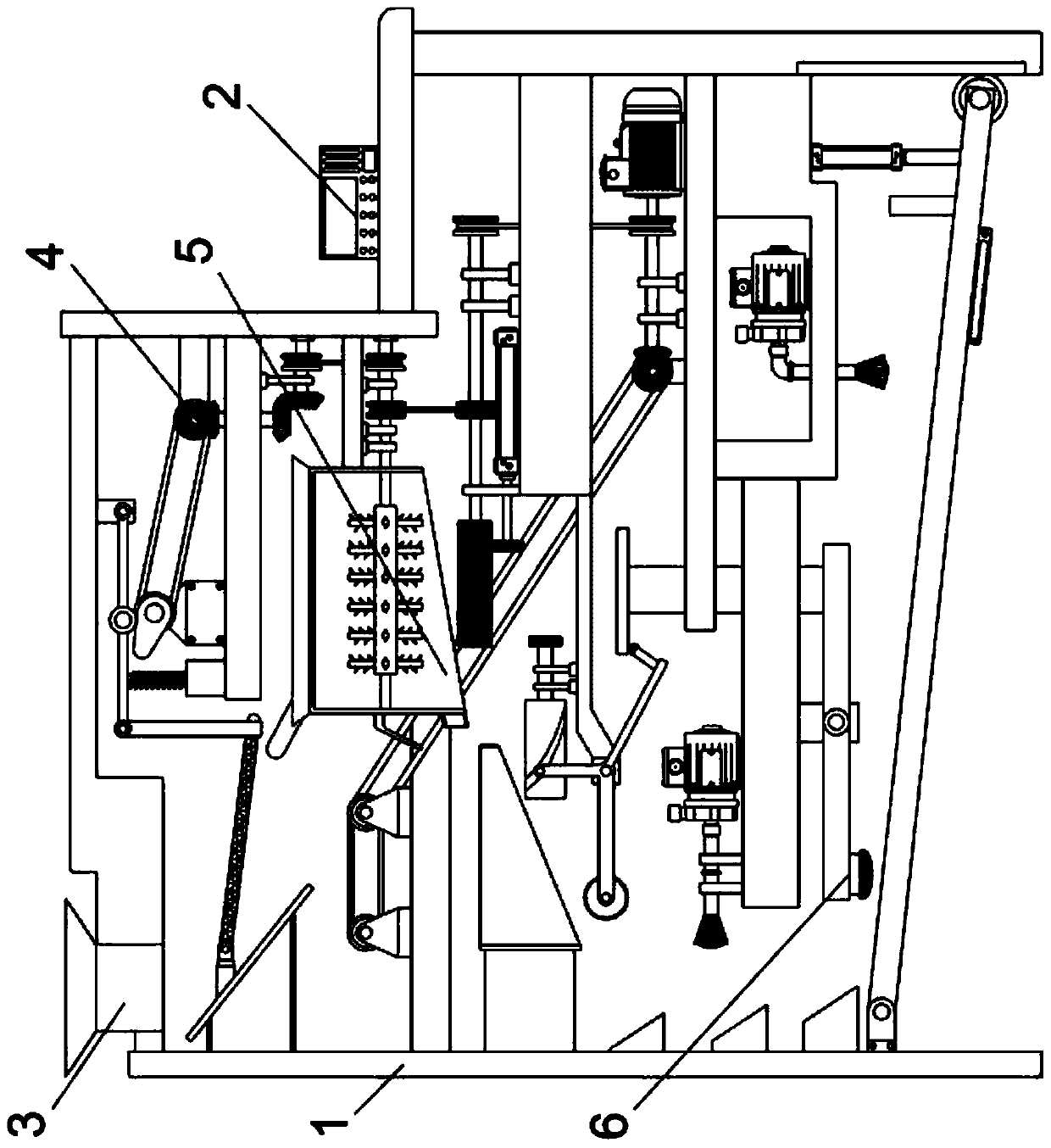

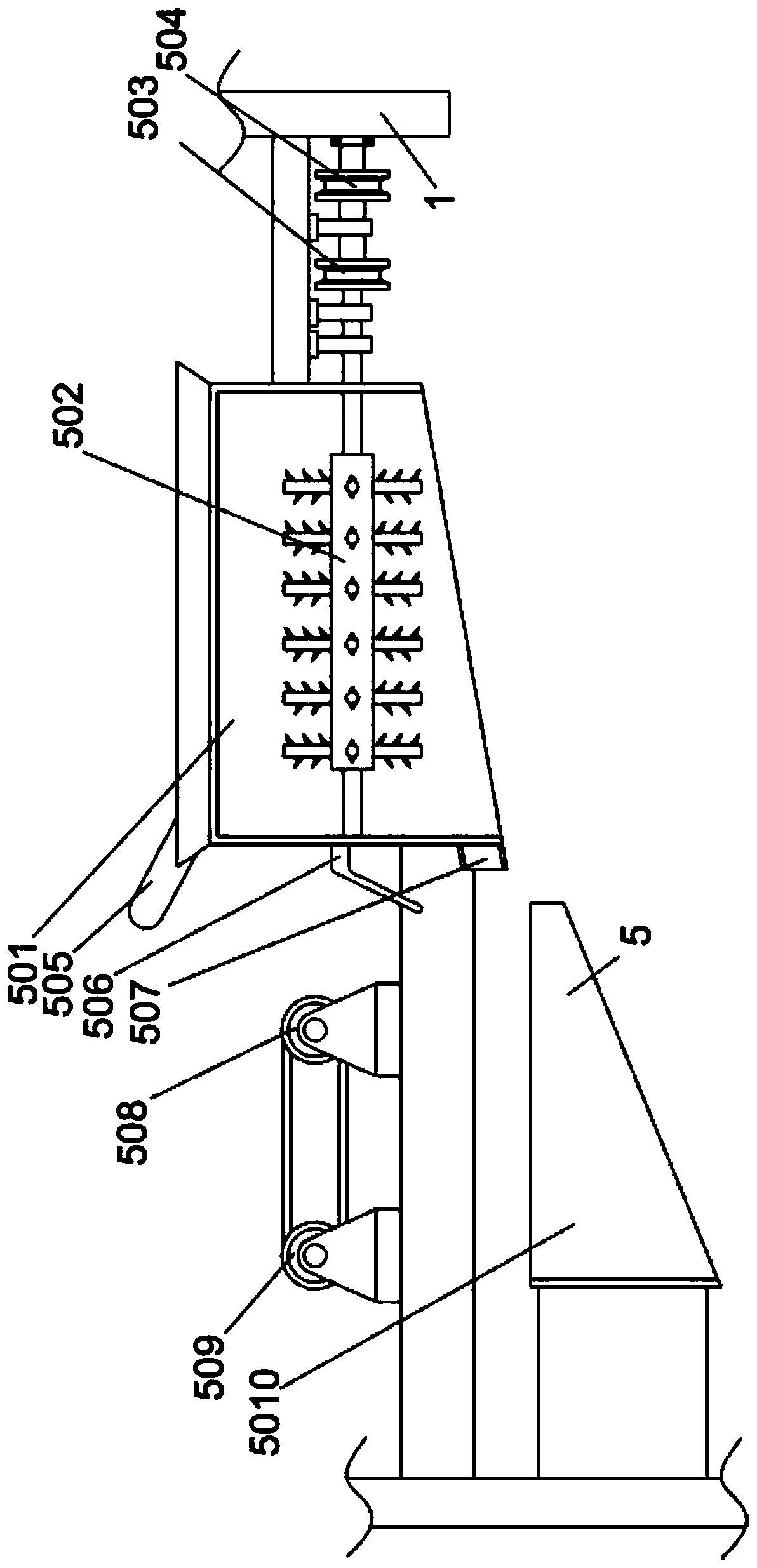

[0027] A masterbatch drying device, such as Figure 1-5 As shown, it includes a bracket 1, a control panel 2, a feed port 3, a screening mechanism 4, a crushing mechanism 5 and a drying mechanism 6; a control panel 2 is provided on the top right of the bracket 1; a feed port is provided on the left top of the bracket 1 3. A screening mechanism 4 is provided on the top of the bracket 1; a crushing mechanism 5 is provided on the top of the bracket 1, and the right part of the top of the crushing mechanism 5 is connected to the screening mechanism 4; the bottom of the bracket 1 is provided with a drying mechanism 6, And the middle right part of the top of the drying mechanism 6 is connected with the pulverizing mechanism 5 .

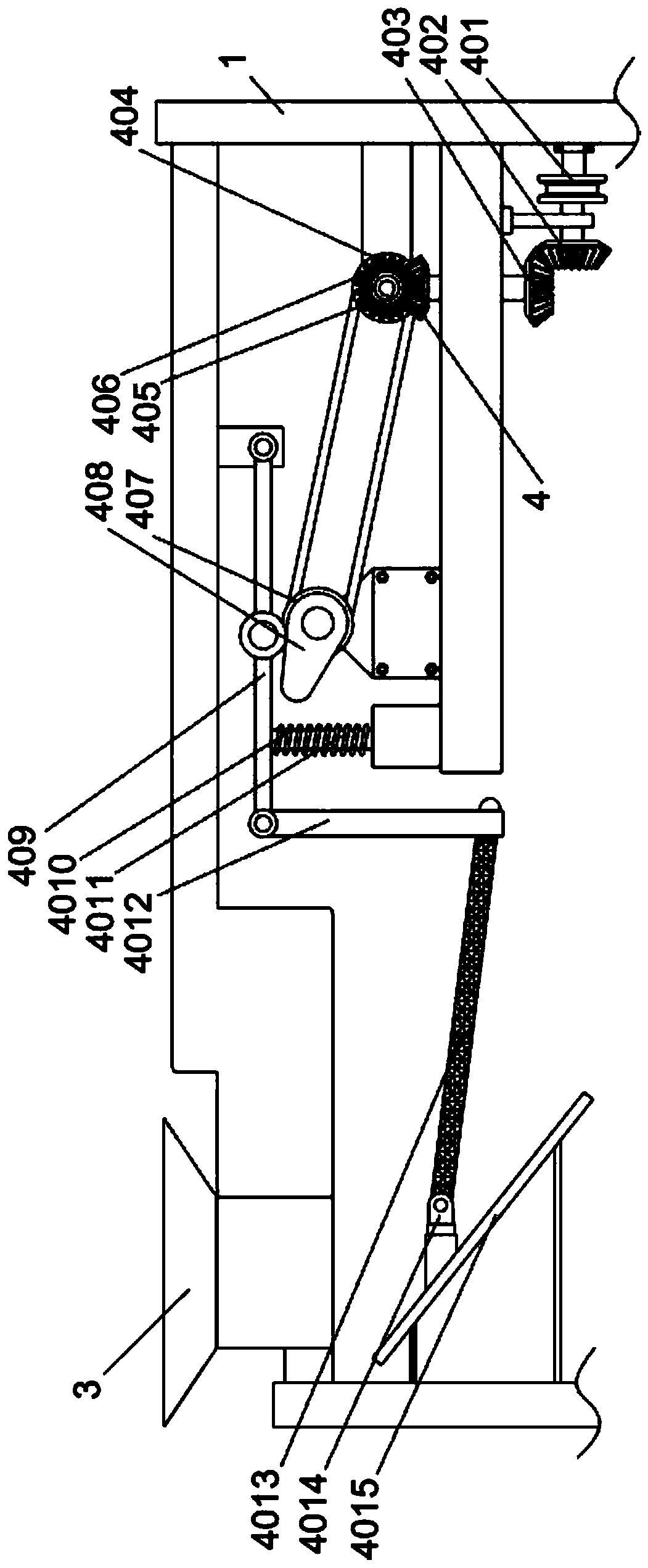

[0028] Wherein, the screening material mechanism 4 comprises a first transmission wheel 401, a first bevel gear 402, a second bevel gear 403, a third bevel gear 404, a fourth bevel gear 405, a second transmission wheel 406, a third transmission wheel 407, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com