Protective surface mortar

A protective surface and mortar technology, applied in the field of building materials, can solve the problems of low bonding strength, high water absorption, insufficient flexibility, etc., and achieve the effects of convenient construction, enhanced surface strength, and reduced wall cracking

Inactive Publication Date: 2019-09-20

CHONGQING QINHENG BUILDING MATERIAL

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to provide a protective surface layer mortar to solve the problems of lo

Method used

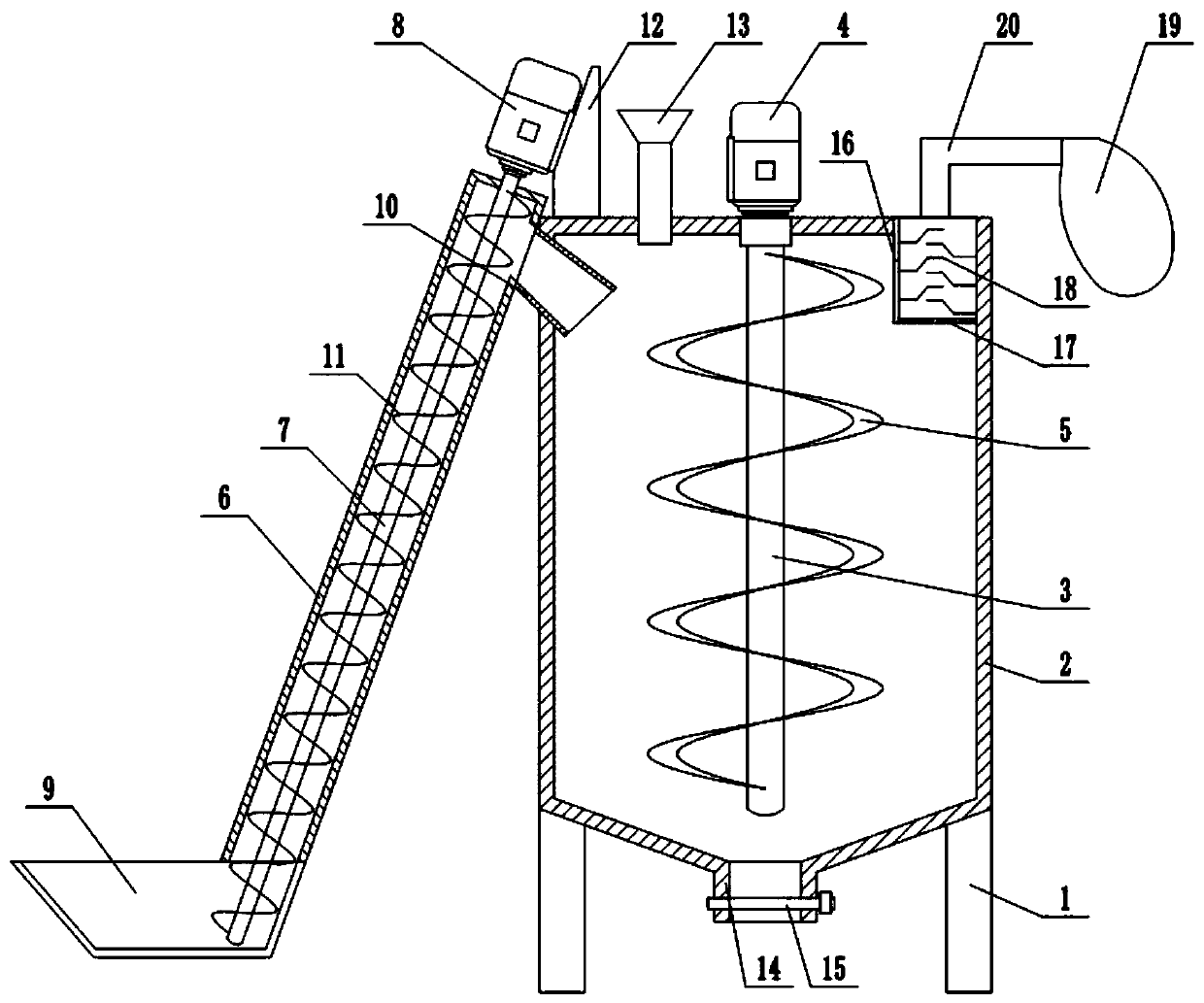

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

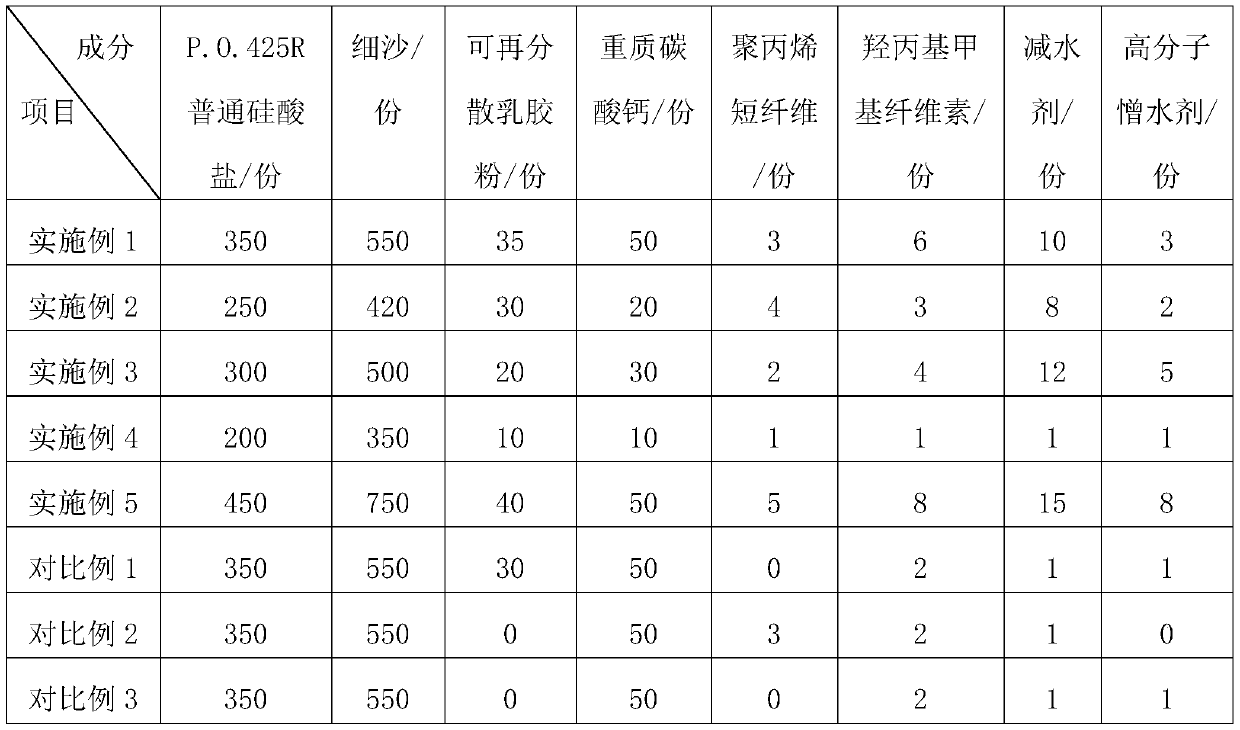

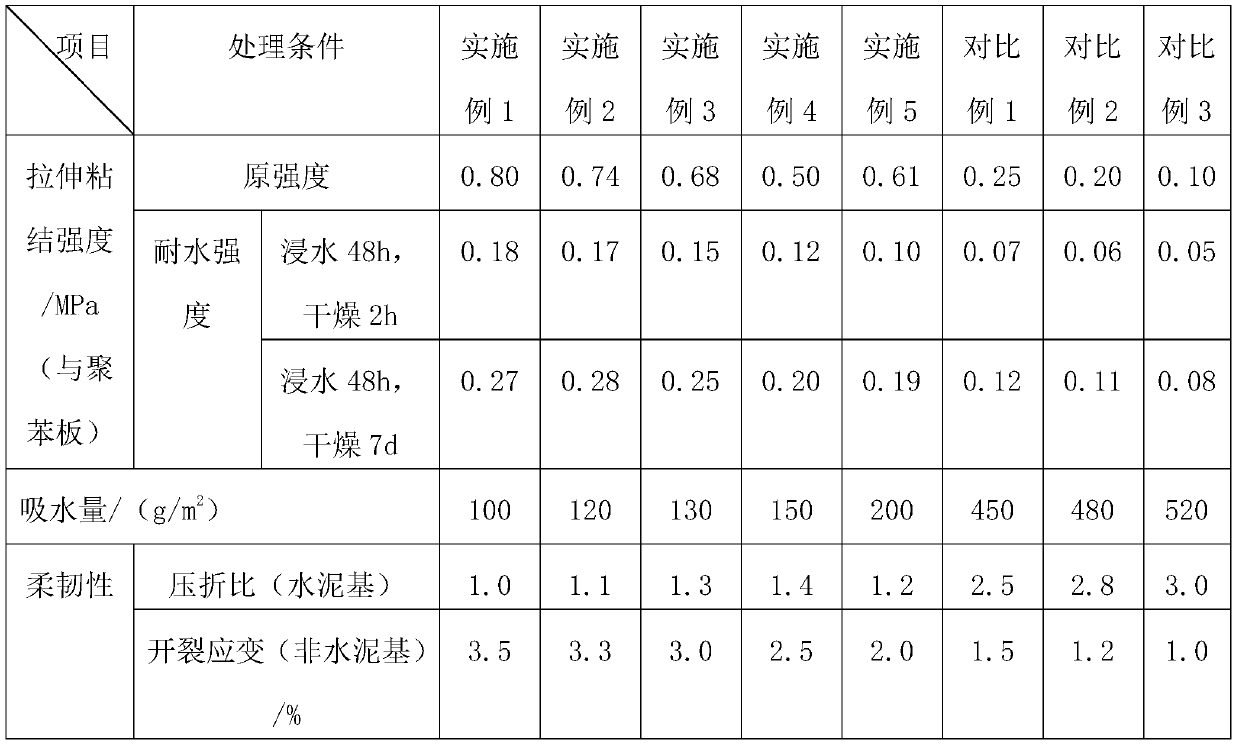

The invention belongs to the technical field of building materials, and concretely discloses protective surface mortar. The protective surface mortar comprises the following components, by mass: 200-450 parts of cement, 350-750 parts of fine sand, 10-40 parts of redispersible latex powder, 10-50 parts of heavy calcium carbonate, 1-5 parts of polypropylene short fibers, 1-8 parts of hydroxypropyl methyl cellulose, 1-15 parts of a water reducer and 1-8 parts of a polymer water repellent. The protective surface mortar of the invention has good bonding strength, flexibility and water resistance, is convenient in construction, non-toxic, green and environmentally friendly, and can be applied to an external wall insulation system to effectively reduce wall cracking, water leakage, peeling, stripping, falling off and the like.

Description

technical field [0001] The invention belongs to the technical field of building materials, and specifically discloses a protective surface layer mortar. Background technique [0002] The energy consumption of China's construction industry accounts for almost 40% of the total industrial energy consumption. It is a long-term and arduous historical task to reduce the energy consumption of the construction industry and strive to improve the living comfort of buildings. The scale of China's buildings is huge, and the main structure of the building is mainly heavy. Under the condition of leapfrog development of building energy conservation, wall insulation technology is a thermal insulation and energy-saving technology with broad application prospects. [0003] The thin plaster insulation system of thermal insulation board is widely used in the internal and external wall insulation system, which uses extruded polystyrene foam board (referred to as XPS board) or expanded polystyren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B111/27

CPCC04B28/04C04B2201/50C04B2111/27

Inventor 韩宁磊

Owner CHONGQING QINHENG BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com