A polyurethane foam insulation and decoration integrated board and its preparation method

A polyurethane foam, integrated board technology, applied in ceramic products, other household appliances, floors, etc., can solve the problems of mechanical properties, poor high temperature resistance and flame retardancy, and achieve excellent fire resistance, low surface tension, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

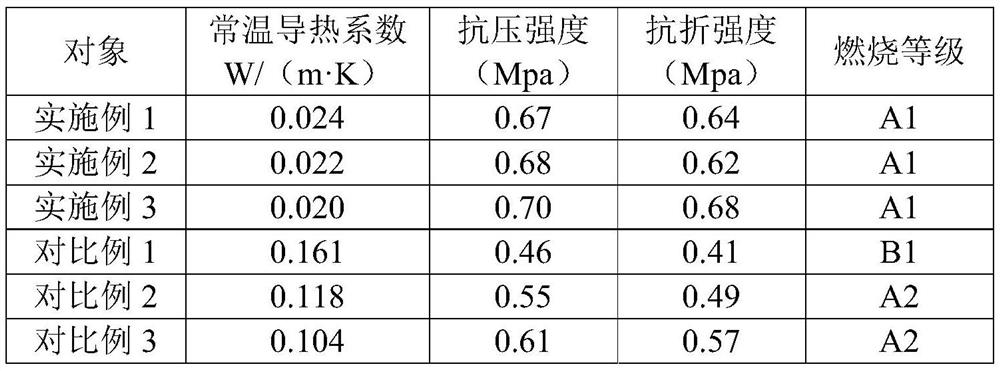

Examples

Embodiment 1

[0031] The polyurethane foam thermal insulation and decoration integrated board of this embodiment includes a facing layer and a base layer, wherein the base layer includes: in parts by weight, 30 parts of modified basalt fiber, modified SiO 2 10 parts of airgel and 60 parts of polyurethane composite material.

[0032] The polyurethane composite material includes: A component and B component with a mass ratio of 1:1; wherein: A component includes: flame-retardant polyester polyol 80wt%, dimethylcyclohexylamine 2wt%, stannous octoate 1wt% , silicone oil 2wt%, glycerin 10wt%, foaming agent 4.9wt% and triethanolamine 0.1wt%; B component is isocyanate.

[0033] The preparation method of the polyurethane foam thermal insulation and decoration integrated board of the present embodiment comprises the following steps: the modified basalt fiber, the modified SiO 2 The airgel is mixed with component A of the polyurethane composite material, and then mixed with component B of the polyur...

Embodiment 2

[0045] The polyurethane foam thermal insulation and decoration integrated board of this embodiment includes a facing layer and a base layer, wherein the base layer includes: in parts by weight, 40 parts of modified basalt fiber, modified SiO 2 20 parts of airgel and 100 parts of polyurethane composite material.

[0046] The polyurethane composite material includes: A component and B component with a mass ratio of 1:2; wherein: A component includes: flame-retardant polyester polyol 85wt%, dimethylcyclohexylamine 2wt%, stannous octoate 0.5wt %, silicone oil 3wt%, glycerin 5wt%, blowing agent 4.2wt% and triethanolamine 0.3wt%; B component is isocyanate.

[0047] The preparation method of the polyurethane foam thermal insulation and decoration integrated board of the present embodiment comprises the following steps: the modified basalt fiber, the modified SiO 2 The airgel is mixed with component A of the polyurethane composite material, and then mixed with component B of the poly...

Embodiment 3

[0059] The polyurethane foam thermal insulation and decoration integrated board of this embodiment includes a facing layer and a base layer, wherein the base layer includes: in parts by weight, 35 parts of modified basalt fiber, modified SiO 2 15 parts of airgel and 85 parts of polyurethane composite material.

[0060] The polyurethane composite material includes: A component and B component with a mass ratio of 1:1.2; wherein: A component includes: flame-retardant polyester polyol 82wt%, dimethylcyclohexylamine 2.5wt%, stannous octoate 0.8 wt%, silicone oil 2.5wt%, glycerin 7wt%, blowing agent 5wt% and triethanolamine 0.2wt%; B component is isocyanate.

[0061] The preparation method of the polyurethane foam thermal insulation and decoration integrated board of the present embodiment comprises the following steps: the modified basalt fiber, the modified SiO 2 The airgel is mixed with the component A of the polyurethane composite material, and then mixed with the component B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com