Formula of novel epoxy millstone floor and preparation method

A new type of epoxy technology, which is applied in the formulation and preparation of new epoxy terrazzo floors, can solve the problems of high cost and thicker epoxy terrazzo floors, and achieve reduced thickness, reduced mesh, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

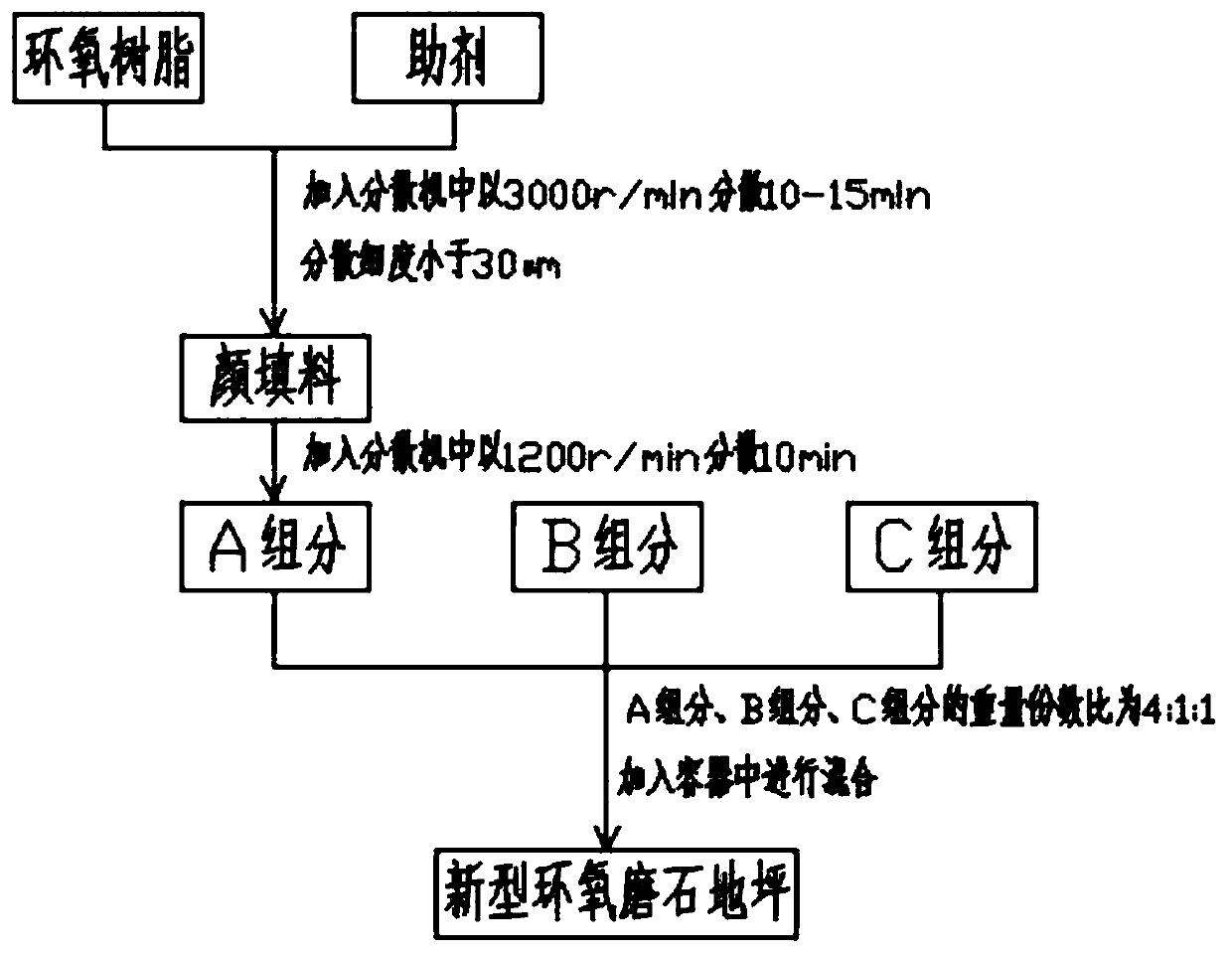

[0031] Such as figure 1 As shown, the present invention proposes a formula and a preparation method of a novel epoxy terrazzo floor, and the preparation method of the novel epoxy terrazzo floor comprises the following steps:

[0032] Step 1. Prepare component A, which contains epoxy resin, pigments and fillers, and additives. The specific mixing steps of component A are as follows:

[0033] Step 1-1, add epoxy resin and additives into the disperser and disperse at 3000r / min for 10-15min;

[0034] Step 1-2. After the dispersion fineness is less than 30μm, add pigments and fillers and disperse at 1200r / min for 5-10min to obtain component A;

[0035] Step 2, prepare component B and component C,

[0036] B component is MDI aromatic polyisocyanate,

[0037] C component contains

[0038] Aggregate of 20-40 mesh sand,

[0039] Aggregate of 80-120 mesh sand,

[0040] The weight and number ratio of the aggregate of 20-40 mesh sand and the aggregate of 80-120 mesh sand is 7:3;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com