Fabricated beam, fabricated double-spliced T-shaped beam and construction method of fabricated double-spliced T-shaped beam

A prefabricated, integrated technology that can be used in building types, protected buildings/shelters, building components, etc., and can solve problems such as unconsidered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

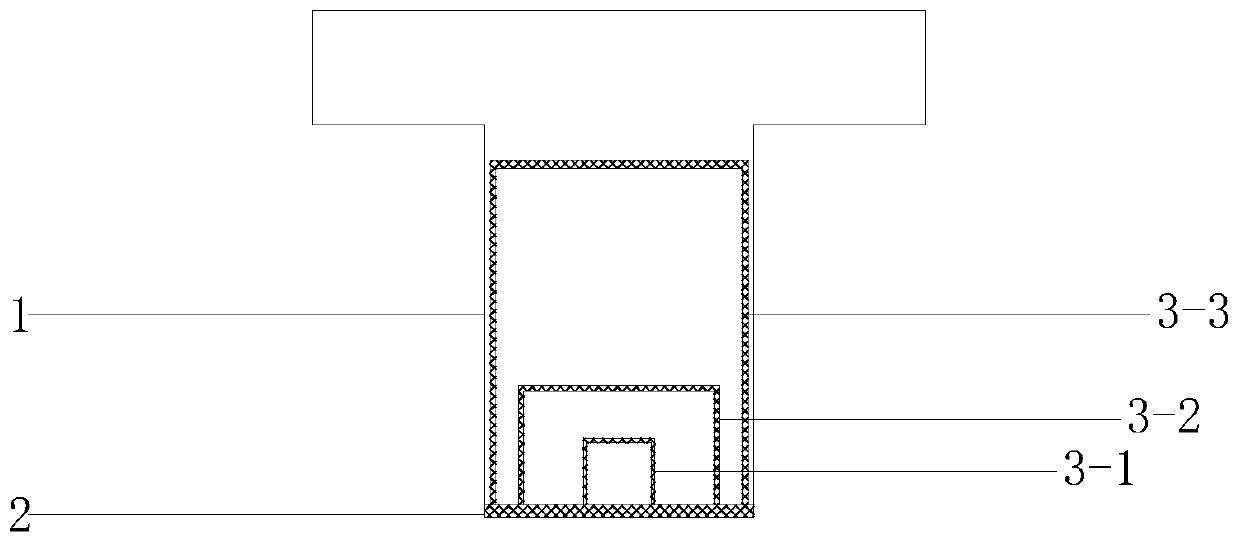

[0046] Embodiment one, such as figure 1 As shown, a prefabricated beam includes a concrete body 1 and a force transmission plate 2;

[0047] The force transmission plate 2 is arranged on the lower surface of the beam, which is used as the formwork of the concrete body; the first C-shaped plate 3-1, the second C-shaped plate 3-2, and the third C-shaped plate 3 are arranged on the upper part of the force transmission plate -3;

[0048] The opening of the first C-shaped plate 3-1 is downward and connected with the force transmission plate 2;

[0049] The opening of the second C-shaped plate 3-2 is downward and connected with the force transmission plate 2;

[0050] The opening of the third C-shaped plate 3-3 is downward and connected with the force transmission plate 2;

[0051]The third C-shaped plate 3-3 wraps the second C-shaped plate 3-2 inside, and the second C-shaped plate wraps the first C-shaped plate 3-1 inside.

[0052] How to avoid slipping between the force trans...

Embodiment 2

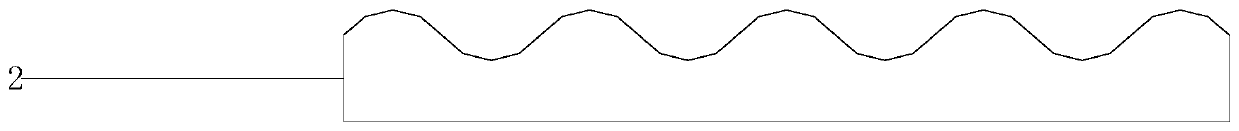

[0053] Embodiment two, in order to further improve the anti-slip effect, such as figure 2 As shown, the upper surface of the force transmission plate is set to be wavy, and it is wavy along the forward direction of the beam; the lower surface of the force transmission plate is provided with racks according to actual needs;

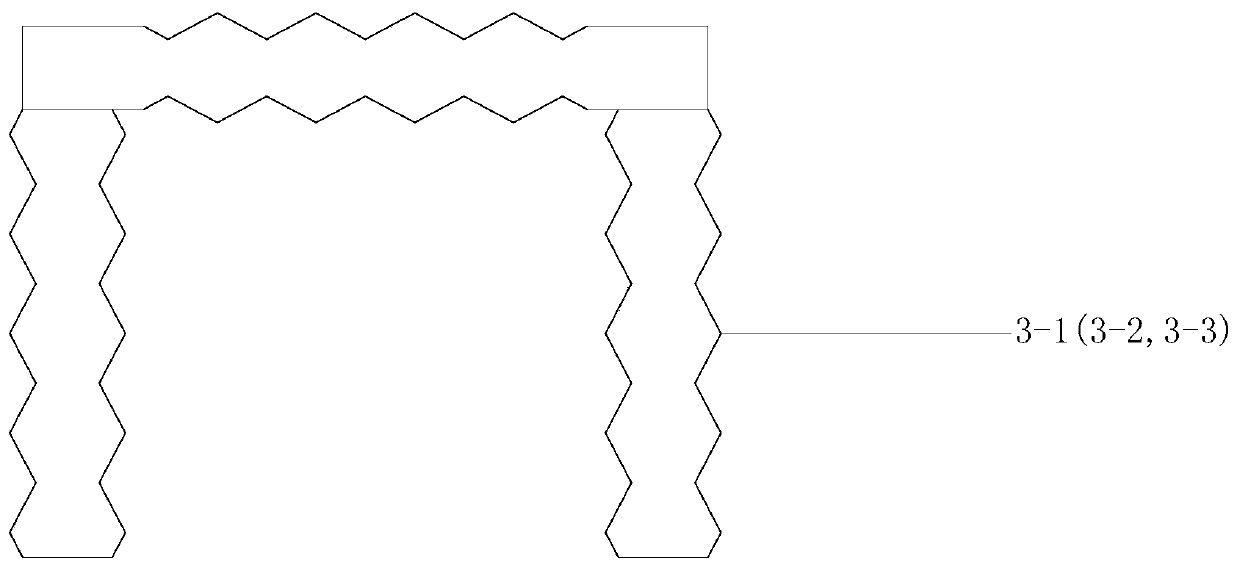

[0054] like image 3 As shown, the inner and outer surfaces of the first C-shaped plate 3-1 are all wave-shaped, the wave shape of the vertical plate of the first C-shaped plate is distributed along the vertical direction, and the wave shape of the horizontal plate of the first C-shaped plate The shape is distributed along the width direction of the beam;

[0055] The inner and outer surfaces of the second C-shaped plate 3-2 are all wave-shaped, the wave-like shape of the vertical plate of the second C-shaped plate is distributed along the vertical direction, and the wave-shaped shape of the horizontal plate of the second C-shaped plate is distributed al...

Embodiment 3

[0058] Embodiment 3, the risk of slippage of the force transmission plate mainly comes from the range where the lower side of the force transmission plate is in contact with the gear, (the gear produces a reaction force on the force transmission plate, and the force transmission plate and the gear are under the action of the earthquake, the transmission The contact point between the force plate and the gear is a range), therefore, under static conditions, the front and rear parts of the position where the force transmission plate is connected to the gear (equivalent to the contact part with the force transmission plate and the gear during work), to strengthen design.

[0059] Within the length L before and after the contact between the force transmission plate and the gear (L is the maximum displacement of the upper beam under the action of a large earthquake), on the basis of the second embodiment, as Figure 4 As shown, the first C-shaped plate, the second C-shaped plate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com