Micro tower type solar heat collecting system

A tower-type solar energy and heat collection technology, which is applied in the field of solar energy collection, can solve the problems of high driving and tracking power requirements, high cost of motor equipment and control costs, and is not suitable for popularization and use. It achieves easy control process, small footprint, The effect of high-speed modular production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

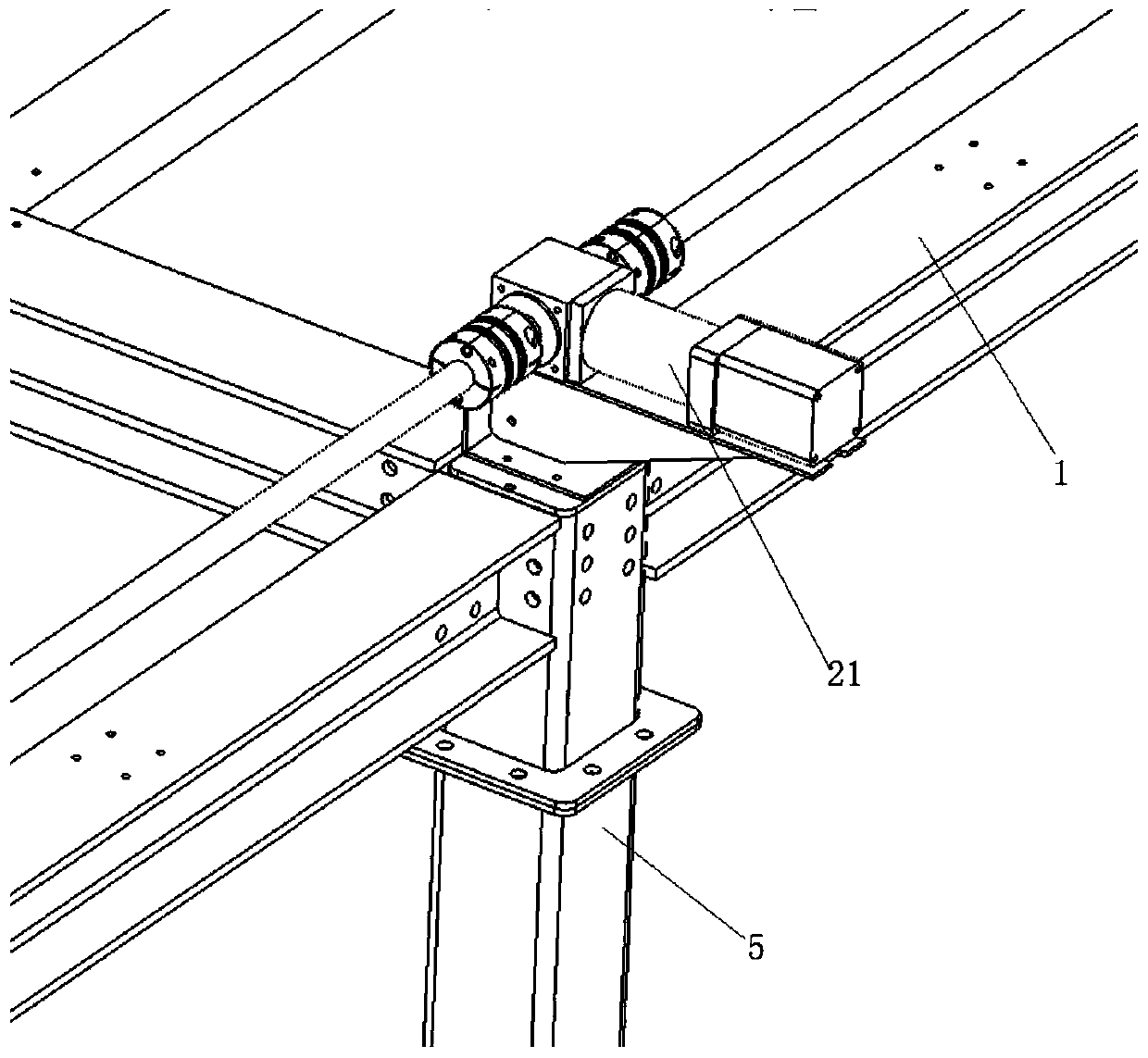

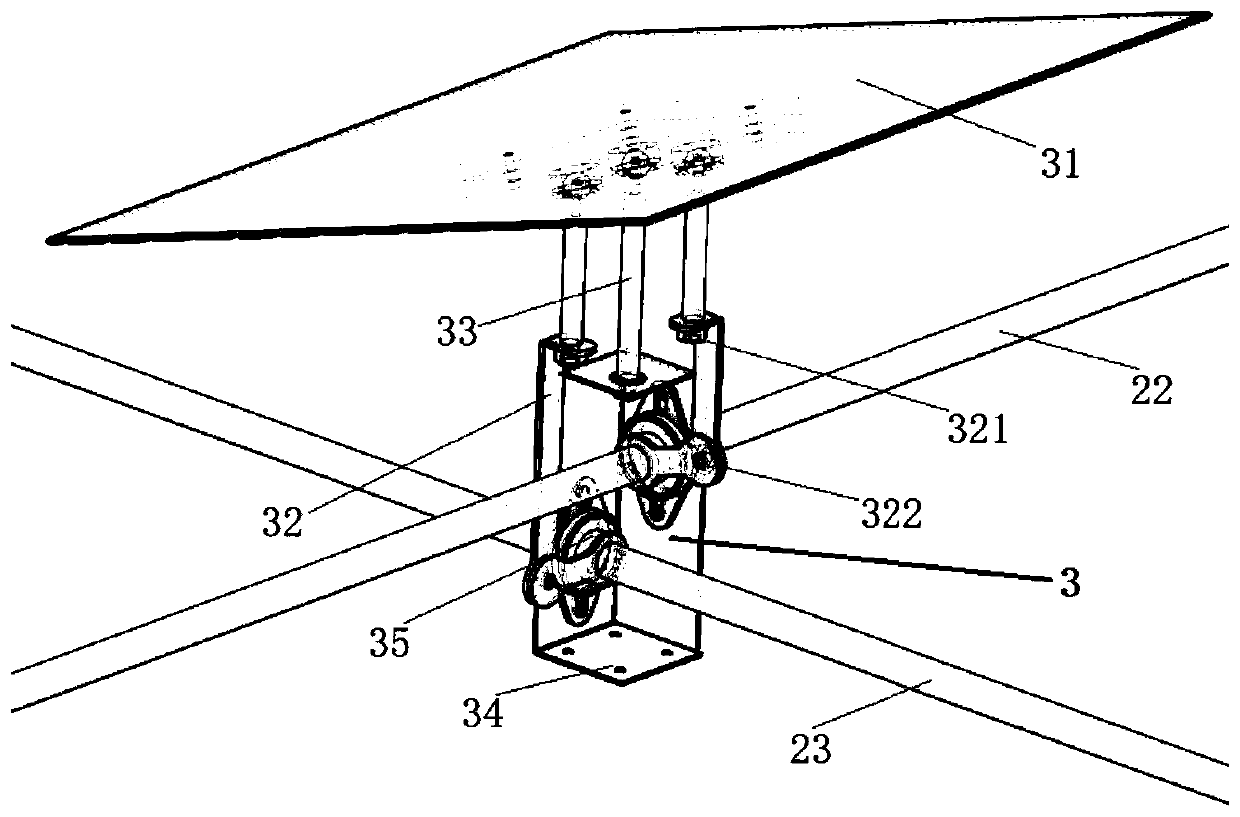

[0055] Such as figure 1 , figure 2 As shown, the micro-tower solar heat collection system includes a frame 1, a transmission device 2, a heat collection unit 3 and a circuit module 4; wherein:

[0056] The transmission device 2 is arranged on the frame 1;

[0057] There are multiple heat collecting units 3, all of which are set on the frame 1 through the transmission device 2;

[0058] The output end of the circuit module 4 is electrically connected to the transmission device 2 .

[0059] In the specific implementation process, the frame 1 is provided with a transmission device 2, and the working state of the transmission device 2 is controlled by the circuit module 4, thereby realizing the overall operation of a plurality of heat collection units 3, forming a multi-heat collection unit 3 The heat collection system reduces the driving power requirements, the whole control process is easy to realize, and the system can be adjusted according to the actual application occasio...

Embodiment 2

[0094] More specifically, on the basis of Embodiment 1, the transmission device also includes a transmission chain, and the transmission chain is arranged on the frame 1; the ends of the longitudinal transmission rod 22 and the transverse transmission rod 23 are all provided with The sprocket is arranged on the transmission chain through the sprocket; the driving motor 21 is connected with the transmission chain for controlling the rotation of the transmission chain.

[0095] In the specific implementation process, through the rotation of the transmission chain, through mechanical linkage and coaxial linkage, the use of motors is reduced, thereby driving the rotation of the longitudinal transmission rod 22 and the horizontal transmission rod 23, and then realizing the control of the heat collection direction of the heat collection unit , effectively reducing the number of driving motors 21, and greatly saving the cost of the system.

[0096] In the specific implementation proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com